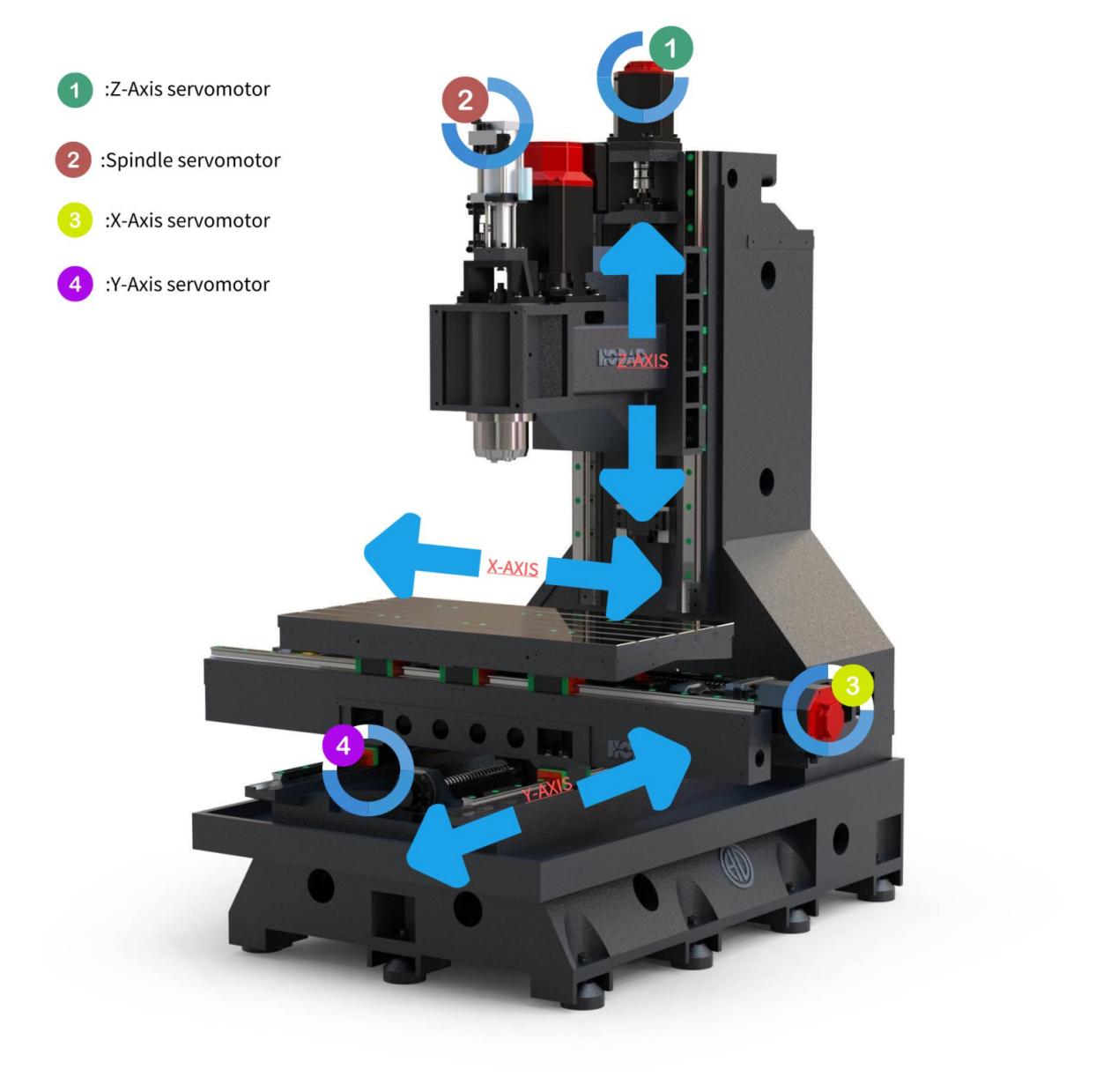

Three axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate linear motion from X, Y and Z three directions to control the workpiece, the position and direction of the tool, to achieve the relative motion of the tool and the workpiece to achieve cutting and other machining processes. The three-axis machining machine is generally composed of a table, three axes of motion (X-axis, Y-axis and Z-axis) and a rotating spindle. The CNC system is programmed to precisely regulate the movement of the servo motor in the direction of the three axes, so that the tool is processed according to the predetermined trajectory and process parameters.

Spindle: Rotate the high-speed spindle to rotate the tool. The spindle motor is placed in the spindle box. 2.

Cross beam: The X-axis slider moves on the X-axis guide of the cross beam to control the movement of the spindle box and the tool in the X-axis direction.

The Y-axis slider moves on the Y-axis guide of the column to control the movement of the spindle and the spindle box in the Y-axis direction. 4.

Z-axis holder: The Z-axis slider moves on the Z-axis guide of the Z-axis holder to control the movement of the spindle box and the tool in the Z-axis direction.

Table: The workpiece is clamped on the table for machining. The table can generally be moved and height adjusted manually or automatically.

Heat exchange system: coolant nozzle, spraying coolant to cool the tool and workpiece during machining.

CNC system: programming and control of machine movement of the computer system, including the display, operating keyboard, etc..

Electrical cabinet: contains the servo motors, drives and control circuits that drive each axis of motion.

Arranging the process flow sheet according to the workpiece design;

Selecting suitable tooling fixtures according to the process flow sheet;

Clamping the workpiece;

Selecting suitable tools;

Writing the CNC program;

Completing the simulation program for machining;

Starting the spindle to turn the tool;

trois axis movement to complete machining;

Spot-checking the machining accuracy during machining;

machining is completed and the workpiece flows to the next process;

Three-axis CNC machining technology is a kind of CNC axis types that is mature and widely used, it can meet most of the general mechanical parts machining requirements, such as flat, slot, hole, spherical and thread. But it also has limitations, and can not achieve complex surface machining and five-axis machining. Nevertheless, as a basic CNC machining method, its position and role in the machinery manufacturing industry will remain for a long time.

China 4-axis CNC machining is a technology to improve the efficiency and accuracy of machining. Traditional 3-axis machines have only the X-axis, Y-axis and Z-axis, which can realize the plane motion and vertical feed of the workpiece. In contrast, 4-axis machining adds an axis of rotation, often referred to as the A-axis or C-axis. This additional axis allows the workpiece to be rotated, which allows the machine to perform more complex machining. You may be interested in professional 4-axis CNC machining manufacturer and get price about our service.

According to the characteristics of the processed workpiece, the fourth axis currently has two structural forms

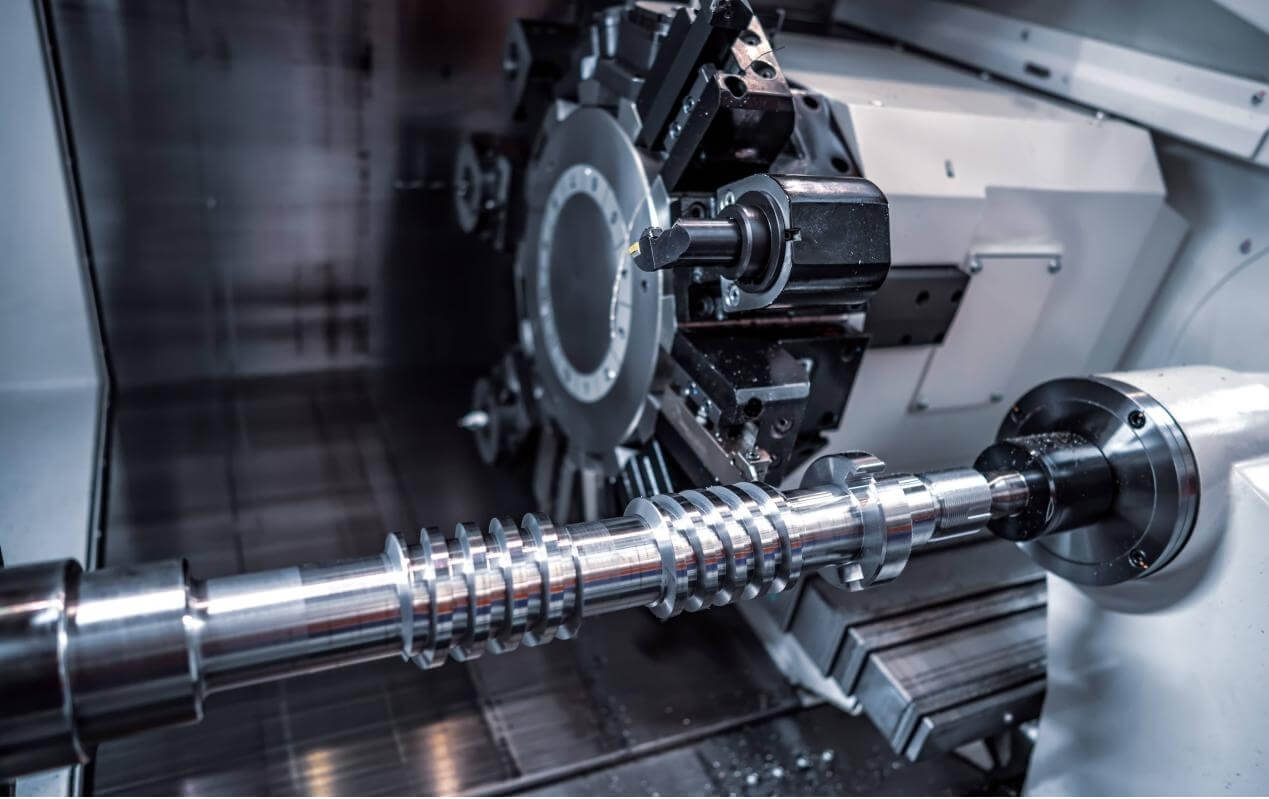

This type of workpiece requires the workpiece to be able to rotate 360 degrees, mostly embodied in screw-type parts. This four-axis machine has the following characteristics

Higher accuracy of the spindle and rotary axis, usually within 0.01 degrees, to ensure high accuracy of the screw surface and threads.

The machine structure is more rigid and can support high-speed and high-efficiency cutting, especially the tread cutting when machining screws.

A professional screw machining control system is available to automatically generate screw machining programs, control spindle speed and feed rate, as well as automatic micrometer and closed-loop control.

The integrated automatic screw micrometer can measure the main parameters of the screw online and feed back to the control system for closed-loop control.

The tool magazine is designed to focus more on screw machining, with more boring tools and pedal tools, and automatic quick tool change mechanism.

There is a special screw machining fixture, which can accurately position and clamp the screw machining parts.

More power for spindle and spindle, higher cutting speed and efficiency can be achieved.

The machine is designed to be more rigid, with large and rigid guideways and drive chains.

Special screw processing equipment, such as tool setting equipment and worm grinding machines, are usually available to achieve fully automated screw processing.

The four-axis machining center for machining non-axis rod workpieces has the following different features compared to the four-axis machining center for screw.

Spindle and rotary axis accuracy is generally within 0.05-0.5 degrees, which does not require as high an accuracy as screw machining. This can reduce the cost of the machine.

The rigidity of the machine structure is generally in the range of 0.05-0.5 degrees, which is not as high as that of screw machining. This also reduces the weight and cost of the machine.

There is no special screw processing control system and automatic micrometer function. The machine is controlled by a common CNC system.

Tool magazine design for screw processing without special tools, general use of general boring tools, milling tools, etc..

There is no special screw machining fixture, using ordinary mechanical fixtures or pneumatic fixtures.

Spindle and spindle power is generally small, usually in the range of 15-30KW, cutting capacity is not as screw dedicated machine tools.

The machine design is more versatile and does not emphasize rigidity as much as screw machines. Therefore, the cost is lower.

There is usually no special screw machining auxiliary equipment.

The ability to machine complex 3D surfaces and mold structures. 4-axis machines can rotate the workpiece through the A-axis to machine a variety of complex 3D surfaces, which is difficult to achieve on 3-axis machines.

Reduced workpiece clamping: 4-axis machining allows the machine to access multiple sides of the workpiece by rotating the workpiece through the A-axis, reducing the number of times the workpiece is repeatedly clamped. This improves machining efficiency and reduces errors.

Full 5-axis continuous machining. A 4-axis machine with A- and C-axes can achieve complex surface machining by rotating the workpiece similar to a 5-axis machine. This results in comparable performance to 5-axis machines, but at a lower cost.

By reducing the number of workpiece clamps and achieving a more stable workpiece orientation, 4-axis machining can minimize machining errors and achieve higher machining accuracy. Therefore, in general, the emergence of 4-axis machining technology has greatly improved the flexibility, efficiency, and accuracy of machining, and is a great advantage for machining workpieces with complex surface structures. It is an important advancement to connect 3-axis machining and 5-axis machining.

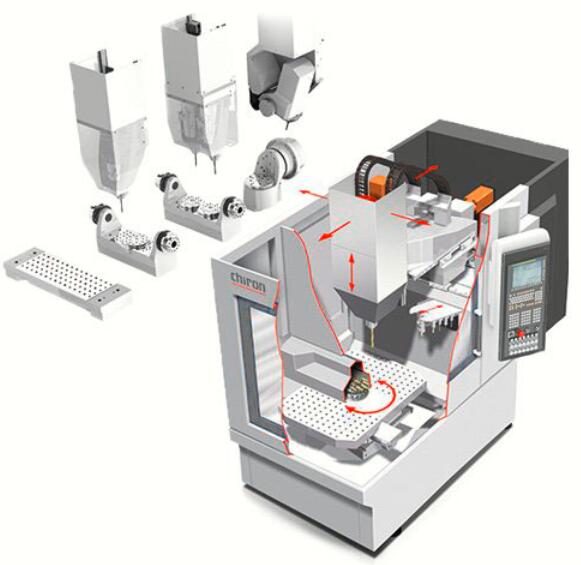

At present, the 5-axis machining center is the most advanced CNC machine tool today, which can process the most complex three-dimensional space surface and form. Five-axis machining center can also be called multi-axis 5 linkage machine tools, through the five mutually perpendicular CNC axis to accurately position the workpiece, to achieve the workpiece in addition to the mounting surface of the five-sided processing, change the relative position and direction between the machine tool and the workpiece, greatly expanding the scope of CNC machining. It can be said that the five-axis machining center is the pinnacle of technological development in the field of machinery industry today, representing the highest level of CNC machining technology. It creates a greater imagination for the high-end equipment manufacturing industry, so that we are confident in the future of precision manufacturing. Five-axis machining center is recognized as an important cornerstone for the development of aerospace, high-speed rail, automotive and other high-end equipment manufacturing. It is also the best processing equipment that can be popularized in large quantities in the industry at present.

What are the differences and advantages and disadvantages of 3 axis OR 4 axis cnc in daily machining production? How to choose?

This we have to judge from several directions, when we process different parts, usually need to consider the processing accuracy, quantity, material, process complexity, and then from the strengths and weaknesses of the two machines to consider. For example:

Need to achieve more complex spatial surface processing when you need to choose 4-axis;

4 axes are also required for machining complex parts (which cannot be repositioned) in one step;

4 axes are required for parts that require higher precision machining;

4 axes when more efficient and competitive machining capability is required;

When choosing between a 4-axis machining center and a 5-axis machining center, each has its own advantages and disadvantages for modern machining processes, we need to consider their cost, efficiency and combined advantages. Here we give some opinions and suggestions in terms of their application areas and costs.

First of all, five-axis machining center is mainly used in high-end equipment manufacturing, such as aerospace, defense weapons, automotive and other industries, these industries require the highest degree of precision and surface complexity of the product, the need for five-axis machining centers such as the most advanced CNC machine tools to meet. Of course, there are many specific products or parts also need, such as: mold parts, various impellers, internal inserts, engine body, etc.. The four-axis machining center has a wide range of applications, in addition to the above high-end industries, but also widely used in the processing of mechanical parts, molds and so on. As long as it does not involve too complex surface processing, four-axis machining center can be competent. So it can be said that five-axis machining center is the high-end field of experts, four-axis machining center is suitable for a wider range of manufacturing.

Further, when we need to consider the cost of processing, we need to list these points. The first five-axis machining center due to the complex structure, high-end configuration, the acquisition cost and use of the most expensive cost. In China, the general brand of five-axis machining center single purchase cost can reach several million yuan or more. Considering the return on investment, the cost per unit time is also relatively high. The price of four-axis machining center is lower than that of five-axis machining center, and the purchase cost of mid-range configuration of four-axis machining center is around several hundred thousand yuan. The cost of use is also more economical than the five-axis machining center.

Therefore, from the application area, five-axis machining center is more high-end professional, four-axis machining center is more widely applicable; from the cost point of view, five-axis machining center is a high-end product, the price is higher, four-axis machining center is more popular and practical, the cost is more economical. Companies can choose the corresponding type of CNC machine according to their business content and budget.

We have introduced various machining processes and machines, here I would like to introduce some information about our company richconn, if you are interested in China 5 axis CNC, please read on.

As a tool for high-precision manufacturing and an important piece of equipment in the machinery manufacturing industry, 5-axis machining centers have always been at the forefront of high-end manufacturing. If you are in these industries (aerospace, medical devices, precision optics) and also need these machining, this should be the right place to come. Here's a little bit about us.

We have many advanced 5-axis CNC machining centers, including German DMG, Japanese Mazak and other brands, which can realize high-precision machining of complex parts below Ø800mm. With more than 10 years of experience in 5-axis machining centers, our programming engineers and machinists can design reasonable machining solutions and procedures, no matter how complex the shape of the part is. In the past, we have been working on a variety of complex curved and shaped parts and have always delivered high quality precision parts that completely meet our customers' technical requirements.

Our 5-axis machining center equipment is the most advanced in the industry, and the high precision of the CNC system and servo drive system can achieve 3μm position repeatability and 0.001° angular control accuracy. At the same time, we implement standardized machining processes and operating procedures, workpiece clamping, tool management and other aspects are carefully designed to maximize the advantages of the machine's machining accuracy, ensuring a high degree of precision of precision parts.

Perfect supporting technology and equipment is also to make us more confident to give you more protection and commitment, online accuracy testing, high-precision CMM testing equipment is also an important tool for us to ensure quality. Optical inspection, metallography, hardness testing, etc. will make our transaction a mutual peace of mind and a worry-free experience.

We provide not only 5-axis machining center services, but also surface treatment of parts such as polishing, plating, and painting. We also have extensive experience and proven processes for these follow-up treatments. In this way, customers only need to provide 2D drawings or 3D models, and we can take care of the rest of the design consultation, processing plan development, manufacturing, post-treatment testing and other whole process services, so as to minimize the follow-up work for customers.

Over the years, we have become major 4-axis CNC machining suppliers to many high-end manufacturing companies by developing and producing 5-axis machining centres and high-precision parts. With our industry-leading 5-axis machining equipment and extensive machining experience, we can handle difficult part machining tasks in a variety of materials and shapes with ease.

We provide not only machining services but also total solutions. From design consultation and machining solutions to subsequent surface treatment, we can take care of everything. This allows the customer to provide only a simple drawing or model to get a complete finished high-precision part. This greatly reduces the customer's workload and subsequent processing costs.

Over the years, we have accumulated a wealth of experience in machining parts for a variety of industries and have developed a comprehensive quality standard system. This allows us to quickly and accurately understand our customers' needs and specifications, and to meet or exceed their expected quality requirements. At the same time, our advanced equipment and rigorous processes allow us to control the high precision and stability of each product. With our strong technical strength and rich industry experience, our 5-axis machining center OEM service has won the high trust of many customers. We sincerely hope to cooperate with more new and old customers, to continue to provide high-standard products and services and to achieve common development and progress.

Alloy Steel vs Carbon Steel: What are the Differences and Advantages?November 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance.view

Alloy Steel vs Carbon Steel: What are the Differences and Advantages?November 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance.view How to Use a Five Axis Machining Center to Process Titanium Alloy Shaped PartsMarch 24, 2023As a five-axis machining center engineer, I will share with you the methods of machining titanium alloy special-shaped parts using a five-axis machining center, as well as the key points of titanium a...view

How to Use a Five Axis Machining Center to Process Titanium Alloy Shaped PartsMarch 24, 2023As a five-axis machining center engineer, I will share with you the methods of machining titanium alloy special-shaped parts using a five-axis machining center, as well as the key points of titanium a...view Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view

Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view Common Inspection Tools and Methods for CNC Parts: Ensuring Quality and PrecisionJune 21, 2024Learn about common inspection tools and methods in CNC machining, such as calipers, micrometers, gauges, projectors, and CMM. Discover how to use these tools accurately for quality control.view

Common Inspection Tools and Methods for CNC Parts: Ensuring Quality and PrecisionJune 21, 2024Learn about common inspection tools and methods in CNC machining, such as calipers, micrometers, gauges, projectors, and CMM. Discover how to use these tools accurately for quality control.view CNC Machining Surface FinishingOctober 23, 2023The surface finishing process is the final step in CNC machining. Different techniques eliminate surface irregularities, improve part appearance, and add strength and resistance for increased functionality. The finishing technique you use depends on specific requirements, such as industry standards, the application of the part, and the materials you are working with.view

CNC Machining Surface FinishingOctober 23, 2023The surface finishing process is the final step in CNC machining. Different techniques eliminate surface irregularities, improve part appearance, and add strength and resistance for increased functionality. The finishing technique you use depends on specific requirements, such as industry standards, the application of the part, and the materials you are working with.view 4 Things You Need to Know About Anodised AluminiumAugust 11, 2023Anodised aluminium has become a buzzword in various industries, from automotive to electronics, and for good reason. This process transforms regular aluminium into a powerhouse material with enhanced ...view

4 Things You Need to Know About Anodised AluminiumAugust 11, 2023Anodised aluminium has become a buzzword in various industries, from automotive to electronics, and for good reason. This process transforms regular aluminium into a powerhouse material with enhanced ...view