Machining tools are vital tools in manufacturing, used to cut, chip, grind and shape a wide range of materials, from metals to plastics to wood. Different tool types are used for different processes and materials to meet a variety of machining needs. Below are five common types of machining tools that are used in a wide range of manufacturing and processing applications.

Drills are a common type of tool used to create holes in materials. They are usually rotating and have multiple cutting edges to remove material quickly and efficiently. Different types of drills are used for different types of materials, including metal, wood, concrete, and plastic. Drill bits come in a variety of shapes and sizes to accommodate a wide range of hole requirements.

Milling cutters are tools used to create flat, contoured and curved shapes. They are usually used in conjunction with a milling machine to remove portions of the material through a rotary motion. Milling cutters can have different cutting edge configurations, including face milling cutters, end mills, and ball end mills for different machining needs. Milling cutters are used for machining metals, plastics, wood and other materials.

Cutting tools are used for cutting operations on rotating workpieces and are usually used on lathes. They can be used to machine round, conical and curved workpieces. Cutting tools usually have a single cutting edge, and they can cut, thread, bore and groove workpieces. These cutters are used in the machining of metals, plastics and wood.

Grinding wheels are tools used for precision grinding and polishing, usually on a grinder. They consist of abrasive grains that grind away the surface of the material to obtain precise dimensions and surface quality. Different types of grinding tools are used for different applications, including surface grinding, external grinding, internal grinding and hollow grinding. Grinding tools are used for machining metals, ceramics, glass and other materials.

Drill and reamers are tools used to machine holes, often to improve the accuracy and surface quality of the hole. They sharpen the bore of a material through a rotary motion and usually have multiple cutting edges. Drill and reamers can be used for machining metals, plastics and wood, and are widely used in areas where high precision holes are required, such as mold making and automotive engineering.

Machining tools and cutting tools are two key concepts in the field of machining that play different but complementary roles in manufacturing and machining processes.

Machining tools is a broad term used to describe the various tools, equipment and machine tools used in the manufacturing process to process raw materials in terms of shape, size and surface quality. Machining tools include the following elements:

Machine Tools: A machine tool is a piece of equipment used to cut, shape and machine a workpiece. Common machine tools include lathes, milling machines, grinding machines, drilling machines, planing machines, boring machines, etc. These machines have different working principles and are suitable for different types of workpieces.

Accessories and Devices: Machining tools also include accessories and devices that are used to aid in the operation of the machine tool, such as fixtures, tool holders, workholding devices, automatic feed systems, CNC controllers, and so on. These accessories and devices can improve productivity and accuracy.

Tools: At the heart of machining tools are the various types of tools that are used to actually cut and remove material or shape the workpiece. These tools can be cutters, drills, milling cutters, grinding wheels, abrasive wheels, cutting blades, etc.

Cutting tools are a subset of machining tools that are specifically used to cut, slice and remove excess material from a workpiece to obtain the desired shape and size. Cutting tools play a key role in metalworking, plastics processing, woodworking and other materials processing. Characteristics of cutting tools include:

Material: Cutting tools are typically made of high hardness, wear-resistant materials to ensure they stay sharp during the cutting process and resist the heat and stress of cutting.

Edge Sections: Cutting tools typically have one or more edge sections that are used to physically cut and remove material from the workpiece. The shape and geometry of the cutting edge varies depending on the cutting task.

APPLICATIONS: Cutting tools have a wide range of applications and can be used for a variety of machining operations such as turning, milling, drilling, grinding, planing, turning external threads, etc.

Cutting process: The selection of cutting tools and the setting of cutting parameters (e.g. cutting speed, feed rate, depth of cut, etc.) depends on the material to be machined and the required workpiece specifications.

Let us now explore in more detail the differences and connections between machining tools and cutting tools:

Machining tools is a broad concept that includes all the tools, equipment and machine tools that are used to machine a workpiece.

Cutting tools are a specific subset of machining tools, which are specialized in tools used to physically cut and remove material.

Machining tools include machine tools, attachments, tools, etc., which together are used to transform a workpiece from raw material to the desired shape and size.

Cutting tool is one of the main tools in machining tools and its main function is to remove material during the cutting process in order to achieve accurate dimensions and surface quality of the workpiece.

Machining tools have a wider scope and can include tools and equipment other than cutting, such as fixtures, CNCs, etc.

Cutting tools are more specialized tools, dedicated to cutting operations.

Cutting tools are usually made of special materials with high hardness and wear resistance to keep the edge portion sharp.

Other parts of a machining tool, such as the machine tool itself or a fixture, are usually made of different kinds of materials.

Machining tools are used throughout the manufacturing process, from the cutting of raw materials to the machining of the final part.

Cutting tools are mainly used for specific cutting operations such as turning, milling, drilling, etc.

Machining tools is a broader concept that encompasses a wide range of tools and equipment used in the manufacturing process, whereas cutting tools are a specific category of machining tools that are specialized in cutting and removing material. There is a connection between the two as cutting tools are an important part of machining tools, but they have different roles and functions. The selection and use of machining tools are critical decisions in manufacturing, and they have a direct impact on the quality, productivity and cost of the workpiece. Therefore, manufacturers and engineers need to carefully consider the characteristics and applications of these tools to obtain optimum machining results.

Richconn, founded in 2008, is a Chinese precision machining company specializing in providing high-quality manufacturing services to our customers. Our diversified business includes CNC machining services, sheet metal services, die casting services, surface treatment services, and 3D printing services. When it comes to precision machining, we understand the critical role that cutting tools play in achieving exceptional results. Just as we strive to exceed our customer's expectations, these cutting tools are essential in bringing every idea to life with precision. Whatever your needs are, Richconn will provide you with innovative, reliable, and efficient solutions, all while leveraging the power of cutting-edge cutting tools.

Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view

Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view The Application of CNC Machining in Mechanical Equipment - CNC PartsMay 13, 2024Discover the wide range of applications and future trends of CNC machined parts in mechanical equipment. From high precision to increased efficiency, this technology is pushing forward the industry. Explore the possibilities now!view

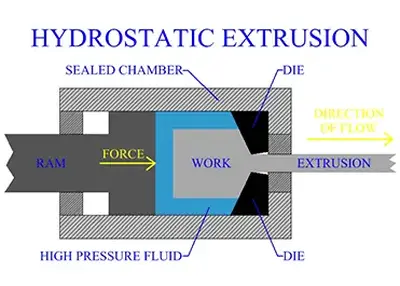

The Application of CNC Machining in Mechanical Equipment - CNC PartsMay 13, 2024Discover the wide range of applications and future trends of CNC machined parts in mechanical equipment. From high precision to increased efficiency, this technology is pushing forward the industry. Explore the possibilities now!view Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

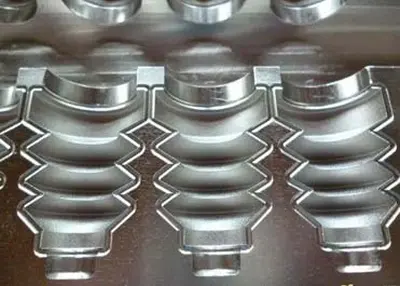

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view Must-Read for Procurement Professionals! 2023 Report on China's Rubber Molds and Parts IndustryAugust 16, 2023Overview: This report provides an in-depth analysis of the development trends, competitive landscape, and key characteristics of China's rubber molds and parts industry in 2023. It serves as an im...view

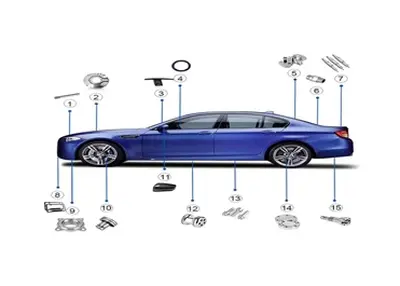

Must-Read for Procurement Professionals! 2023 Report on China's Rubber Molds and Parts IndustryAugust 16, 2023Overview: This report provides an in-depth analysis of the development trends, competitive landscape, and key characteristics of China's rubber molds and parts industry in 2023. It serves as an im...view The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view

The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view How to Produce High-quality Parts With CNC?June 25, 2024The passage mainly talks about the production progress of high-quality parts with the help of CNC. It’s strongly recommended that Richconn is an effective company, which owns many technicians and advanced technology.view

How to Produce High-quality Parts With CNC?June 25, 2024The passage mainly talks about the production progress of high-quality parts with the help of CNC. It’s strongly recommended that Richconn is an effective company, which owns many technicians and advanced technology.view

EN

EN

ru

ru