Aero-engine is the "heart" of the aircraft, also known as the "pearl in the crown of industry", the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields. With each country's engine performance requirements are getting higher and higher, in the research and development, the application of new structures, new technologies, new techniques and so on are still constantly challenging the peak of modern industry. And one of them plays an important role in improving the thrust-to-weight ratio of the aero-engine, which is the integral impeller.

Before the emergence of the integral impeller, the rotor blade of the engine needs to be connected to the wheel disk through the tongue and groove, tongue and groove and locking device, etc., but this kind of structure gradually fails to meet the needs of high-performance aero-engines. Engine rotor blades and wheel integrated whole leaf disk was then designed, has become a high thrust-to-weight ratio engine structure, in the military, civil aviation engines have been widely used, the main advantages are as follows.

As the rim of the disk does not need to be machined to install the blade of the tongue and groove, the radial dimensions of the rim can be greatly reduced, thereby significantly reducing the mass of the rotor.

In addition to the fact that the disk and the blades become one piece, the reduction of the locking device is also an important reason. Aero-engine reliability requirements are extremely stringent, simplified rotor structure has a great role in improving reliability.

Elimination of fugitive flow loss caused by the gap in the traditional connection method improves engine efficiency and increases thrust.

Both reduce weight and increase thrust, so conducive to improving the thrust-to-weight ratio of the integral impeller is naturally not easy to pick the "jewel". On the one hand, the whole leaf disk mostly use titanium alloy, high temperature alloy and other difficult to process materials; on the other hand, its blade is thin and complex leaf type, which puts forward very high requirements for manufacturing technology. In addition, the rotor blade damage can not be replaced separately, which may lead to the scrapping of the whole leaf disk, repair technology is another problem.

At present, the manufacturing of the whole leaf disk has three major technologies.

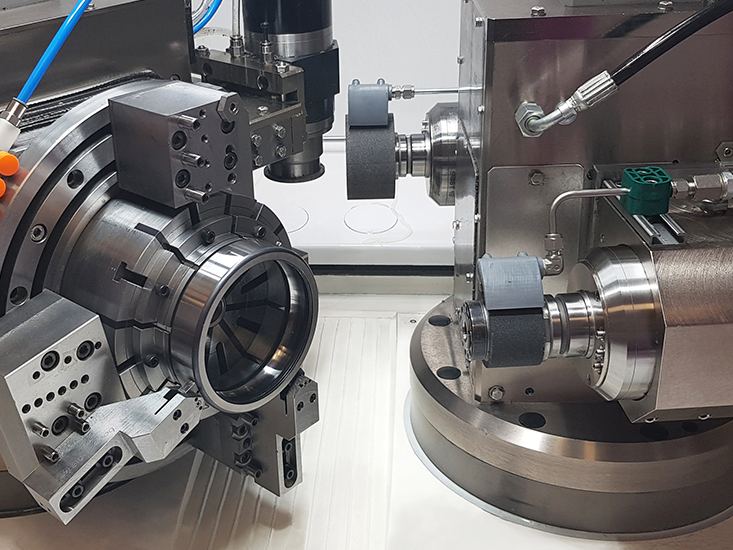

5-axis CNC milling processing due to its rapid response, high reliability, processing flexibility and production preparation cycle is short, etc., in the overall leaf disk manufacturing field has been widely used, the main side milling, insert milling and pendulum milling milling mode. And the key factors to ensure the success of overall leaf disk machining include:

(1) five-axis linkage machine tools with good dynamic characteristics

2) Optimized professional CAM software

3) Specialized tools and application knowledge for titanium/high temperature alloy machining

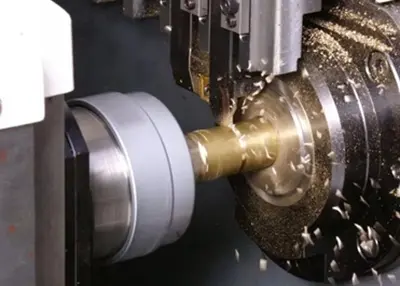

Electrochemical machining method is an excellent method of machining the whole leaf disk channel of an aero-engine, in electrochemical machining there are mainly electrolytic nesting, profiling electrolytic machining as well as CNC electrolytic machining and other machining techniques.

Since electrochemical machining mainly utilizes the property of anodic dissolution of metal in electrolyte, the cathode part does not produce loss when applying electrochemical machining technology, and the workpiece will not be affected by the cutting force, machining heat, etc., which reduces the residual stress of the aero-engine overall blade channel after machining.

In addition, compared with five-axis milling, electrochemical machining of the working hours are greatly reduced, and in the roughing, semi-finishing and finishing stages can be used, no need to hand-polish after machining, so it is the aero-engine overall impeller channel machining is one of the important development direction.

Individual processing of the blade, and in the later stage of the use of electron beam welding, linear friction welding or vacuum solid-state diffusion joint welding technology will be pre-processed blade welding to the blade disk. The advantage is that it can be used for the manufacture of the whole blade disk where the blade and disk materials do not coincide.

The welding process requires high quality of blade welding, which directly affects the performance and reliability of the whole blade disk of the aero-engine. And because the actual shape of the blade used in the welded blade disk is not consistent, by the welding precision limitations of the blade in the welded position is not consistent, the need to use adaptive machining technology for each blade for personalized precision CNC milling.

In addition, the whole leaf disk repair, welding is a very important technology, which linear friction welding as a solid-phase welding technology, welded joints of high quality, good reproducibility, welding high thrust-to-weight ratio of aero-engine rotor parts more reliable and reliable welding technology.

EJ200 aero-engine has a total of 3-stage fan and 5-stage high-pressure compressor. Individual blades are electron beam welded to the rotor disk to form a monolithic disk, which is used in the 3rd stage fan and the 1st stage high pressure compressor. The rotor and other rotor stages are not welded together to form a multi-stage rotor, but are connected by short bolts, which is generally in the initial stage of the application of the integral blade disk.

F414 turbofan engine, 3-stage fan stage 2, 3 and 7-stage high-pressure compressor of the first three stages of the use of the whole impeller, using electrochemical processing and become. And GE also developed a feasible repair method, based on which the integral impellers of the 2nd and 3rd stages of the fan were welded together to form an integral rotor, and the 1st and 2nd stages of the compressor were also welded together, which further reduced the weight of the rotor and improved the durability of the engine.

Compared to the EJ200, the F414 is a big step forward in the application of the integral lobe disk.

The 3-stage fan and 6-stage high-pressure compressor all adopt the integral impeller, and the 1st stage fan blade is hollow, and the hollow blade is welded to the rotor disk by linear friction welding to form the integral impeller, which reduces the weight of the rotor of this stage by 32kg.

In the civilian large engine, the whole leaf disk has also been applied. BR715 engine using five-axis linkage CNC milling technology processing the whole leaf disk, used in the fan after the second stage of supercharged compressor, and before and after the two stages of the whole leaf disk welded together to form a whole rotor. It is used in Boeing 717.

The wide application of integral lobe disk technology represents a continuous endeavor for excellence in the field of modern aero-engines. It has had a profound impact not only in military aviation, but even in civil aviation. In the future, with continued R&D efforts, we can expect more innovations in the field of integral lobe disk design and manufacturing to further improve the performance and efficiency of aero-engines. Just as the aviation industry continues to break new heights, integral lobe disk technology is a testament to the relentless pursuit of excellence in aerospace engineering.

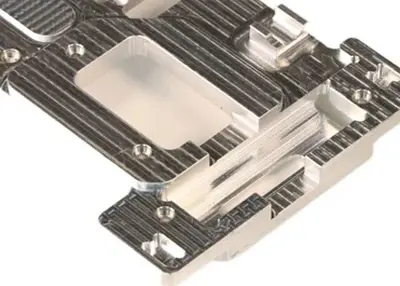

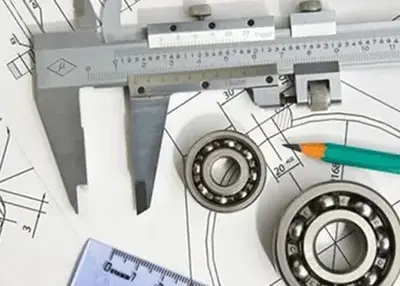

In this exciting field, Richconn, established in 2008, stands out for its excellent precision machining services. as a precision machine shop, we proudly offer CNC turning and CNC milling services in a wide range of materials, as well as outstanding sheet metal fabrication services. richconn has always been committed to the spirit of continuous improvement and excellence in providing aerospace engineering and other customers in the aerospace engineering and other sectors, providing excellent support to ensure that their projects are designed and manufactured for optimum performance and reliability. Richconn looks forward to continuing to work with its customers to drive innovation in the aerospace industry as integral blade technology and other areas of precision machining continue to evolve.

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view What five axes does the five axes machining center have?March 6, 2023Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position ...view

What five axes does the five axes machining center have?March 6, 2023Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position ...view What Is CNC Machining? The Basic Information You Need to KnowMarch 27, 2024What is CNC machining? Here is the basic information that you must know, such as its advantages, disadvantages, applications, and so on.view

What Is CNC Machining? The Basic Information You Need to KnowMarch 27, 2024What is CNC machining? Here is the basic information that you must know, such as its advantages, disadvantages, applications, and so on.view Authoritative Guide to Tack Welding & Efficient Welding ProcessSeptember 19, 2023Welding is a long-standing process that remains essential in various industries. Manufacturers employ different types of welds depending on the project's requirements. Tack welding is particularly...view

Authoritative Guide to Tack Welding & Efficient Welding ProcessSeptember 19, 2023Welding is a long-standing process that remains essential in various industries. Manufacturers employ different types of welds depending on the project's requirements. Tack welding is particularly...view Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view

Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view Fundamentals and Techniques of Engineering DrawingsDecember 1, 2023Engineering drawings are a graphical language used to express engineering design ideas and details, and they are an important tool for engineers for design, manufacturing and maintenance. Engineering drawings follow a number of international or national standards and specifications to ensure the accuracy, consistency and readability of engineering drawings.view

Fundamentals and Techniques of Engineering DrawingsDecember 1, 2023Engineering drawings are a graphical language used to express engineering design ideas and details, and they are an important tool for engineers for design, manufacturing and maintenance. Engineering drawings follow a number of international or national standards and specifications to ensure the accuracy, consistency and readability of engineering drawings.view

EN

EN

ru

ru