Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific chemical properties that are suitable for various applications. When choosing the right material for steel CNC machining, it is important to consider the distinct properties of alloy steel and carbon steel. Though both alloy steel and carbon steel are different types of steel, they have some differences.

How to select the proper steel becomes a big challenge in manufacturing CNC machined components. In this article, we take a look at the difference between carbon steel vs alloy steel, including types, applications, alloying elements, and properties.

Alloy steel is a type of steel that contains additional alloying elements such as manganese, silicon, chromium, nickel, molybdenum, or vanadium. The addition of these alloying elements enhances specific properties, such as strength, toughness, hardenability, and corrosion resistance.

Some of the alloying elements and their effects are shown below.

Cobalt

Enhances the strength and hardness of steel.

Manganese

Enhances the response to heat treatment and promotes work hardening.

Chromium

Increases corrosion resistance, improves hardenability, and enhances wear resistance.

Molybdenum

Molybdenum increases the strength, hardenability, and toughness of steel.

Nickel

Improves corrosion resistance, enhances strength at high temperatures, and promotes ductility.

Vanadium

Refines grain size and improves impact resistance.

Tungsten

Enhances hardness, wear resistance, and toughness.

Chromium-Vanadium

Provides good wear resistance and can withstand high temperatures.

Alloy steel is created by combining steel with a variety of components to produce distinctive characteristics and properties. There are two general types of alloy steel: high-alloy steel and low-alloy steel.

High-Alloy steel:

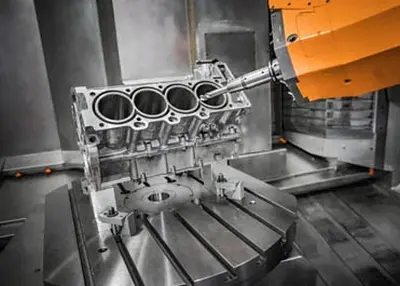

High-alloy steel contains a high percentage of alloying elements such as chromium, nickel, molybdenum, and vanadium. These alloys enhance the mechanical properties of the steel, including its strength, hardness, and corrosion resistance. High-alloy steels are commonly used in applications where extreme strength and durability are required, such as in aerospace, automotive, and power generation industries.

Low-Alloy Steel:

Low-alloy steel contains a lower percentage of alloying elements compared to high-alloy steel. These alloys are typically added in smaller quantities to improve specific characteristics of the steel such as its weldability, toughness, and formability. Low-alloy steels are often used in structural applications, such as construction, and in the manufacturing of machinery and equipment.

To put it simply, carbon steel is an alloy of carbon and iron. The amount of carbon present in carbon steel determines its properties and applications. It is one of the most commonly used materials in the manufacturing industry due to its strength, durability, and affordability.

Low-carbon steel

Also known as mild steel, it contains a low percentage of carbon (up to 0.3%). It is relatively soft and easy to work with, making it suitable for applications such as automotive components, structural beams, and sheet metal fabrication.

Medium-carbon steel

With a higher carbon alloy (between 0.3% and 0.6%), medium-carbon steel offers increased strength and hardness compared to low-carbon steel. It is commonly used for machinery parts, axles, gears, and railway tracks.

High carbon steel

This type of carbon steel contains a carbon content ranging from 0.6% to 1.5%, making it exceptionally strong and hard. High-carbon steel is mainly used for manufacturing cutting tools, springs, and high-strength wires.

Understanding the Differences Between Alloy Steel vs Carbon Steel

Alloy steel and carbon steel are two distinct types of steel that differ in their composition and properties. Here are the main differences between them:

1. Composition

Carbon steel is primarily composed of iron and carbon, with trace amounts of other elements. Alloy steel is made by adding various alloying elements such as manganese, chromium, nickel, or vanadium to improve specific properties.

2. Applications

Carbon steel is widely used in industries such as construction, manufacturing, and automotive, where strength, affordability, and versatility are important. Alloy steel, with its enhanced mechanical properties, is commonly used in applications that require higher strength, temperature resistance, wear resistance, or corrosion resistance, such as aerospace, oil and gas, and power generation.

3. Corrosion resistance

Carbon steel is susceptible to corrosion, especially in humid or corrosive environments, unless it is protected with a coating or treated. Alloy steel, through the addition of certain alloying elements, can provide improved resistance to corrosion, making it suitable for applications in harsh environments.

4. Hardness

Alloy steel, due to its alloying elements, can exhibit higher hardness compared to carbon steel.

5. Strength

Alloy steel often exhibits higher tensile and yield strength compared to carbon steel due to the presence of alloying elements.

6. Toughness

Carbon steel generally possesses good toughness, which is its ability to withstand impact and deformation without fracturing. Alloy steels with specific alloying elements can have enhanced toughness, making them suitable for applications that require resistance to impact or shock.

7. Malleability

Carbon steel has good malleability, allowing it to be easily shaped and formed into various shapes or structures. Alloy steel, depending on its specific alloying elements, can have varying degrees of malleability.

8. Weldability

Carbon steel is generally easier to weld compared to alloy steel. Alloy steel may require additional pre- or post-weld heat treatment or special welding techniques to avoid certain issues like cracking or loss of properties.

Weldability

9. Ductility

Carbon steel is known for its high ductility, which is its ability to deform under tensile stress without fracturing. Alloy steel can have different levels of ductility depending on its composition and treatment.

10. Cost

Carbon steel, being a simpler composition, is generally more cost-effective compared to alloy steel. Alloy steel, with its added alloying elements and enhanced properties, can be more expensive.

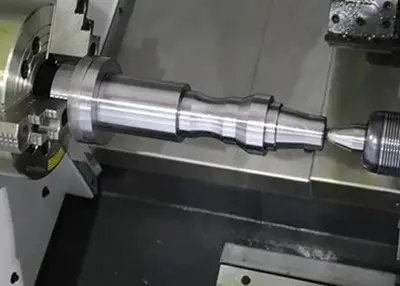

It's important to note that the specific properties and performance of both alloy steel vs carbon steel can vary depending on the specific grades and treatments used. These steels' formability, cost-effectiveness, and recyclability have a considerable impact on industrial usage. if you need a steel CNC machining partner with exceptional machining capabilities, Richconn is your best choice.

Richconn offers unparalleled expertise and a stringent quality control system in CNC machining, ensuring that you can have high-quality metal parts delivered to you with a short lead time. Let's get started on your project today!

Different Types of Lathe Tools for CNC Lathe Machine and ApplicationsJanuary 10, 2024What are lathe tools? What are their essential components, types and classifications? Trust Richconn as your reliable partner for CNC machining solutions.view

Different Types of Lathe Tools for CNC Lathe Machine and ApplicationsJanuary 10, 2024What are lathe tools? What are their essential components, types and classifications? Trust Richconn as your reliable partner for CNC machining solutions.view Differences Between Chrome, Galvanized and Nickel PlatingOctober 20, 2023The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties.view

Differences Between Chrome, Galvanized and Nickel PlatingOctober 20, 2023The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties.view How to Find the Right Manufacturing PartnerOctober 13, 2023It’s worth taking the time to find a supplier that’s a perfect fit for the buyer’s company. Think of it as a partnership in which both parties are committed and invested. In the digital age, it is increasingly advisable to also consider additional total cost of ownership (TCO) savings.view

How to Find the Right Manufacturing PartnerOctober 13, 2023It’s worth taking the time to find a supplier that’s a perfect fit for the buyer’s company. Think of it as a partnership in which both parties are committed and invested. In the digital age, it is increasingly advisable to also consider additional total cost of ownership (TCO) savings.view Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view

Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view Fillet Meaning: What Are Fillets in CNC Manufacturing?September 27, 2023Fillets are rounded corners that help increase strength and prevent rapid deformation at a part’s corners. Take a look at the fillet definition!view

Fillet Meaning: What Are Fillets in CNC Manufacturing?September 27, 2023Fillets are rounded corners that help increase strength and prevent rapid deformation at a part’s corners. Take a look at the fillet definition!view Different Types of Iron: Introduction, Properties, and UsesApril 28, 2024Iron is versatile and has various types with different applications. The right iron is selected based on its benefits. Richconn's expertise makes them outstanding in cast iron part machining.view

Different Types of Iron: Introduction, Properties, and UsesApril 28, 2024Iron is versatile and has various types with different applications. The right iron is selected based on its benefits. Richconn's expertise makes them outstanding in cast iron part machining.view

EN

EN

ru

ru