The world of manufacturing has witnessed a revolutionary transformation with the advent of Computer Numerical Control (CNC) technology. This advanced machining process has significantly enhanced precision, efficiency, and versatility in component production. In this comprehensive guide, we will explore the various facets of CNC machined parts, their importance, and the diverse industries they serve. Richconn is a leading CNC machining companies in china, prviding custom CNC maching with different CNC machinig materials

Centrally, the essence of CNC machining lies in its employment of computer technology to direct machine tools. This method ensures cuts, shapes, and dimensions that are not only precise but also highly accurate. Crucially, this advanced technique plays a pivotal role in crafting components to meet stringent specifications impeccably. It spans the gamut from basic bolts to the intricately complex components found in the aerospace industry. The flexibility and precision afforded by parts of a CNC machine have changed manufacturing processes, enabling the production of high-quality parts with consistent standards across large quantities, thereby making it indispensable in modern manufacturing.

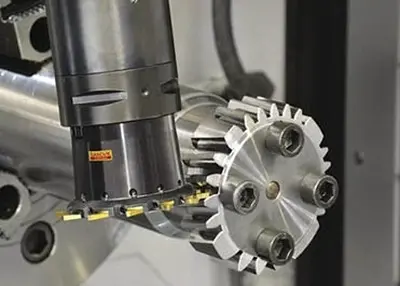

Within the realm of CNC machining, milling emerges as a remarkably adaptable process. Leveraging spinning cutters, it adeptly carves away at materials, bequeathing workpieces with intricate geometries and characteristics. An array of milling machines - encompassing the vertical, horizontal, and sophisticated 5-axis variants - presents a spectrum of flexibility and exactitude, catering to diverse machining needs.

Synonymous with the term "lathes", turning machines orchestrate a mesmerizing dance wherein the workpiece twirls, met by a deft cutting tool that sculpts it into forms both elegant and precise. This method shines when crafting cylindrical or tubular elements, boasting an uncanny ability to churn out parts with impeccable symmetry, concentricity, and a finish as smooth as silk.

When the task calls for the puncturing of workpieces, CNC drilling machines step into the limelight. Capable of executing an assortment of drilling maneuvers—including, but not limited to, spot drilling, counterboring, and tapping—these machines bring a unique efficiency to batch production. Their unerring accuracy in hole placement speaks to a level of repeatability that is both impressive and essential.

For those occasions where a delicate touch is paramount, CNC grinding machines deliver. With their abrasive wheels whirring into action, they meticulously pare down materials, bestowing upon the workpiece a refined shape and dimensions. In industries where parts must adhere to stringent tolerances and sport an immaculate surface finish—bearings and engine components among them - grinding machines are invaluable.

Stepping beyond traditional cutting methods, EDM embarks on a journey at the forefront of non-traditional CNC machining. Through the cunning use of electrical discharges, it erodes material from the workpiece, which can’t be handled by conventional techniques. Wire EDM and sinker EDM, each with its singular merits, broaden the horizon of what is possible in precision machining.

In the world of precision CNC machining, these five techniques—milling, turning, drilling, grinding, and EDM - represent the backbone of a field where innovation and precision converge. Whether shaping metals into art or giving form to functional masterpieces, these processes stand as a testament to human ingenuity and the enduring pursuit of perfection.

The industrial sector is one of the largest consumers of CNC machined parts. From assembly lines to heavy machinery, these components are integral to maintaining smooth operations and enhancing productivity. CNC machine part often describes the individual elements that contribute to the bigger picture of industrial efficiency.

The aerospace industry demands unparalleled precision and quality in its components. aerospace CNC machining plays a crucial role in producing CNC machining aerospace parts that meet the stringent requirements of safety and reliability. These parts must withstand extreme conditions and perform flawlessly, making CNC technology an indispensable tool for manufacturers.

Similarly, the automotive industry relies on CNC machined parts to push the boundaries of innovation. With automotive CNC machining parts, designers and engineers can create intricate components that improve vehicle performance and fuel efficiency while also enhancing aesthetic appeal.

One of the great advantages of CNC machining is its ability to work with a wide range of materials. CNC machined aluminum parts are particularly popular due to aluminum's strength, lightweight properties, and corrosion resistance. This versatility allows for the creation of components tailored to specific applications and environments.

Every CNC machined part begins with a carefully designed blueprint or 3D model. This design phase is critical as it determines the functionality and performance of the final product. Software programs translate these designs into instructions that CNC machines can interpret, ensuring every cut and shape aligns with the original plan.

The actual machining process involves the conversion of raw materials into precise components through cutting, milling, drilling, or other subtractive processes. The phrase "cnc machined part" typically refers to this stage, where material is shaped under the guidance of computer-controlled tools.

After machining, each part undergoes rigorous quality control checks to ensure it meets the specified standards. This includes inspections for dimension accuracy, surface finish, and material integrity. Only those parts that pass these tests are approved for use in their designated applications.

CNC machined parts have dramatically increased productivity across various industries by enabling mass production with consistent quality. This has led to shorter lead times and reduced costs, ultimately benefiting both manufacturers and consumers.

The precision afforded by CNC technology also contributes to more sustainable practices. By minimizing waste and optimizing material usage, CNC machined parts help conserve resources and reduce environmental impact.

Perhaps one of the most significant advantages of CNC machining is its capacity for customization. Manufacturers can produce CNC machines parts tailored to specific needs, driving innovation and satisfying unique customer demands.

In the nuanced world of CNC machining, the selection of materials is akin to choosing the right pigments for a masterpiece. The decision hinges on a confluence of factors such as mechanical attributes, environmental stipulations, and the distinct demands of the intended use. Here's an exploration of materials frequently embraced in the realm of CNC machining:

Aluminum: Celebrated for its featherweight nature, resistance to corrosion, and willingness to be shaped, aluminum stands as a luminary in the world of machinable materials.

Stainless Steel: With its robust strength, stellar corrosion resistance, and its adeptness in the medical and culinary domains, stainless steel emerges as a beacon of reliability.

Titanium: Marrying lightweight appeal with substantial strength and commendable biocompatibility, titanium finds its niche in the lofty skies of aerospace and the intricate world of medical devices.

Brass: Renowned for its electrical conductivity prowess, resilience against corrosion, and its frequent starring role in aesthetic and electrical components, brass is a player to watch.

Steel: For applications demanding unwavering strength and longevity, steel steps forth as a versatile champion.

ABS (Acrylonitrile Butadiene Styrene): Lauded for its durability and capacity to withstand impacts, ABS finds widespread favor in consumer products and the dynamic automotive landscape.

Nylon: Boasting impressive strength and wear resistance, nylon is a go-to material for mechanisms like gears and bearings that demand toughness.

Polycarbonate (PC): Prized for its clarity and impact resistance, polycarbonate takes center stage in safety glasses, electronic casings, and automotive elements where transparency and resilience are key.

Polypropylene (PP): Featuring a lightweight frame and commendable chemical resistance, polypropylene is a versatile actor in packaging, automotive advancements, and the meticulous medical sector.

Acrylic: Cherished for its transparent charm and UV defense, acrylic illuminates pathways in display creations, signage articulation, and illumination projects.

This curated selection of metals and plastics serves as a foundational element in CNC machining, offering builders and dreamers alike a palette from which to draft their mechanical masterworks.

Just as an artist relies on their colors to bring a vision to life, so too do designers and engineers depend on these materials to fabricate reality from imagination.

The act of choosing the right material for CNC machined parts is akin to laying the foundation for a triumphant structure—it dictates functionality, longevity, and fiscal prudence. As you embark on this selection journey, look at the CNC material list to guide your decision:

Scour the mechanical landscape for your part's unique needs—be it the sinews of strength, the veneer of hardness, or the shield against impacts. Align these specifications with materials that flaunt the necessary traits.

Ponder the realm where your part will dwell. Some materials may wilt under corrosion’s touch, crumble under extreme heat, or dissolve in chemicals. Settle on materials that vow compatibility with their destined use.

Weigh the economic scales of diverse materials, factoring in both their market value and the expenditure on machining. Striking a balance between performance ambitions and financial feasibility is paramount.

Remember, each material possesses its unique demeanor towards machining; some revel in the process, while others pose challenges due to inherent hardiness or heat tolerance. Ensure your chosen material dances well with CNC machining choreography.

For parts bound by industry strictures or certification mandates, tread carefully in selecting materials that align with these overarching requirements—especially in arenas like aerospace and healthcare, where compliance reigns supreme.

If your application whispers of tight tolerances, heed the call of materials renowned for their dimensional constancy, ensuring precision in every form and function.

In environments where temperatures soar, pick materials unflinching in the face of thermal trials, promising no distortion nor decay under heated duress.

Assess the necessity for materials that stand firm against corrosion, especially for components grappling with dampness, chemicals, or the corrosive claws of harsh settings.

Where appearance matters, opt for materials that can be crafted, painted, or textured to manifest the coveted visual allure.

Experience precision and innovation with Richconn's CNC machining services. Leveraging cutting-edge technology and a passionate team of experts, Richconn delivers exceptional craftsmanship across various industries. Trust us for your complex aerospace parts, robust automotive components, and precise medical devices. Partner with Richconn for unparalleled quality and service in turning your vision into reality.

Innovative Synergy: Richconn shines as a beacon in the bustling world of CNC machining, offering not just materials but a synergy of innovation, reliability, and meticulous craftsmanship.

Team of Experts: With an array of premium materials and a team of experts united by a passion for precision, Richconn emerges as your go-to ally for transforming vision into reality through mastery of CNC machining.

Versatile Capabilities: Richconn delivers excellence in every cut, shape, and finish, whether your needs demand the intricacy of aerospace parts, the robustness of automotive components, or the delicate precision of medical devices.

Understanding and Service: Entrusting your CNC machining projects to Richconn means embracing a partner who understands the essence of your needs and is dedicated to ensuring your success through unmatched quality and service levels.

Wide Applicability: CNC machining stands as an industrial titan, transforming manufacturing landscapes across various sectors. From soaring aircraft to intricate medical devices, the reach of CNC-machined components is extensive.

Precision Technology: With insights into the essence of CNC machining, its multifaceted applications, and prevailing precision techniques, you are equipped to navigate the nuances of this groundbreaking technology.

Material Selection: Always consider key elements when choosing materials for CNC machined parts, trusting that Richonn remains your steadfast partner in precision and expertise on your manufacturing journey.

With Richconn by your side, you can embark on your manufacturing adventures with confidence, knowing your visions are in the hands of artisans and innovators who live to turn possibilities into realities.

As technology continues to advance, the possibilities for CNC machining seem endless. We can expect further advancements in precision, speed, and material capabilities, opening new frontiers for CNC machined parts in fields ranging from medicine to space exploration.

CNC machined parts stand at the forefront of modern manufacturing, providing unparalleled precision, efficiency, and versatility. From the bustling assembly lines of the automotive industry to the cutting edge of aerospace research, these components play a crucial role in driving innovation and sustaining progress. Don’t hesitate to start your CNC machining project now!

CNC Water Jet Cutter: Precision in Cutting TechnologySeptember 28, 2023Have you ever dreamed of achieving flawless precision in cutting materials, from metal to delicate fabrics, with utmost efficiency and accuracy? Your dream can become a reality with the marvel of technology known as the CNC Water Jet Cutter.view

CNC Water Jet Cutter: Precision in Cutting TechnologySeptember 28, 2023Have you ever dreamed of achieving flawless precision in cutting materials, from metal to delicate fabrics, with utmost efficiency and accuracy? Your dream can become a reality with the marvel of technology known as the CNC Water Jet Cutter.view What is the Basic Principle of Electrophoresis Coating?September 16, 2022Electrophoresis coating is a coating method that uses an external electric field to make particles such as pigments and resins suspended in an electrophoretic solution directionally migrate and deposi...view

What is the Basic Principle of Electrophoresis Coating?September 16, 2022Electrophoresis coating is a coating method that uses an external electric field to make particles such as pigments and resins suspended in an electrophoretic solution directionally migrate and deposi...view What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view

What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view CNC Honing Service A Guide for Concept & SelectionMay 20, 2024CNC honing service helps to achieve tighter tolerances and better surface finishes on a wide range of precision machined parts with a round bore. Here's a simple guide for its concept and selection.view

CNC Honing Service A Guide for Concept & SelectionMay 20, 2024CNC honing service helps to achieve tighter tolerances and better surface finishes on a wide range of precision machined parts with a round bore. Here's a simple guide for its concept and selection.view Surface Treatment for CNC Machining PartsApril 4, 2023CNC machining can produce precision parts with strict tolerances and fine parts from various metal or plastic materials. Due to the influence of factors such as plastic deformation during chip separat...view

Surface Treatment for CNC Machining PartsApril 4, 2023CNC machining can produce precision parts with strict tolerances and fine parts from various metal or plastic materials. Due to the influence of factors such as plastic deformation during chip separat...view How to Define Fits: Different Types of Fits in EngineeringMarch 5, 2024This article will shade some light on “fits”. To know more about “what is fits” will help you succeed in doing your projects. So let’s check it out.view

How to Define Fits: Different Types of Fits in EngineeringMarch 5, 2024This article will shade some light on “fits”. To know more about “what is fits” will help you succeed in doing your projects. So let’s check it out.view