The continuous improvement of the automation degree of 4-axis CNC machining and the development of mechanized systems make the process scope continue to expand. 4-axis CNC machining maximizes the continuous, efficient and high-precision machining of multiple surfaces, multiple features, and multiple stations after the workpiece is clamped at one time, that is, the process is concentrated. But a 4-axis CNC machining can only work its best under the right conditions. So, what are the main workpieces for 4-axis CNC machining?

The market demand of some products is cyclical and seasonal. If a special production line is used, it will not be worth the loss. The processing efficiency of ordinary equipment is too low, and the quality is unstable and the quantity is difficult to guarantee. If 4-axis CNC machining is used, the program and related production information can be retained after the trial cutting of the initial batch of workpieces. The next time the product is remanufactured, production can start with minimal preparation time. 4-axis CNC machining man-hours include preparation man-hours and processing man-hours. 4-axis CNC machining evenly distributes long single-piece preparation man-hours to each workpiece, reducing the average actual man-hours for each production and greatly shortening the production cycle.

Some workpieces have very little demand, but are key components, and require high precision and short construction period. Using traditional processes requires multiple machine tools to coordinate work, resulting in long cycle and low efficiency. loss.

The flexibility of CNC 4-axis machining production is not only reflected in the rapid response to special requirements, but also can quickly achieve mass production to improve market competitiveness. 4-axis CNC machining is suitable for small and medium batch production, especially small batch production. When applying 4-axis CNC machining, try to make the batch larger than the economic batch to achieve good economic results. With the continuous development of 4-axis CNC machining, the economic batch is getting smaller and smaller. For some complex workpieces, 5~10 pieces can be produced, and even single-piece production can be considered with Zhongshan 4-axis CNC machining.

The application of 4-axis CNC machining and the maturity and development of CAD and CAM technology have greatly improved the complexity of the workpiece. The use of DNC makes the processing content of the same program sufficient to meet various processing needs, making the CNC automatic lathe processing of complex workpieces easy.

After the CNC machining center is equipped with a fourth axis, it is usually called a 4-axis CNC machining center. It can complete the tasks that three-axis machine tools cannot process at one time. It is realized by the rotation of the fourth axis or the fourth axis bridge plate. The multi-faceted processing of the processed products not only overcomes the processing that cannot be completed by the three-axis machine tool, but also greatly improves the processing efficiency of the machine tool, reduces the number of clamping times, and increases the efficiency of the enterprise.

As a leading 4-axis CNC machining supplier in China, Richconn provides quality 4-axis machining services. Feel free to contact us at any time.

Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view

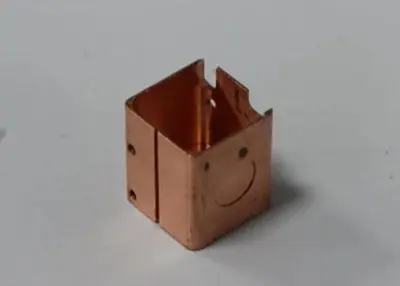

Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view A Comprehensive Copper Analysis for CNC MachiningJanuary 12, 2024Here are various properties of copper - from its elemental essence, physical prowess, thermal and electrical properties, to applications in CNC machining.view

A Comprehensive Copper Analysis for CNC MachiningJanuary 12, 2024Here are various properties of copper - from its elemental essence, physical prowess, thermal and electrical properties, to applications in CNC machining.view Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view

Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view Unlocking Creativity: Exploring the World of CNC Acrylic MachiningNovember 15, 2023Welcome to the realm where precision meets creativity, where the art of CNC (Computer Numerical Control) technology converges with the transparent beauty of acrylic. In this journey, we will delve into the intricate world of CNC Acrylic machining, unveiling its applications, design inspirations, material synergies, and real-world case studies.view

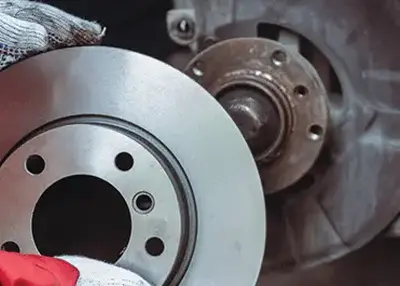

Unlocking Creativity: Exploring the World of CNC Acrylic MachiningNovember 15, 2023Welcome to the realm where precision meets creativity, where the art of CNC (Computer Numerical Control) technology converges with the transparent beauty of acrylic. In this journey, we will delve into the intricate world of CNC Acrylic machining, unveiling its applications, design inspirations, material synergies, and real-world case studies.view What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view

What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view What Are the Characteristics of the Surface Treatment Process for Titanium Alloy Materials?October 30, 2023Titanium alloys are a variety of alloy metals made of titanium and other metals, which are relatively scarce and expensive; titanium alloys are characterized by high strength, light weight, corrosion resistance and high temperature resistance, and can be used in a variety of fine chemicals, which are mainly used in the automotive industry, aerospace, nuclear industry, chemical and petrochemical industries, dentistry and medical restoration and other fields.view

What Are the Characteristics of the Surface Treatment Process for Titanium Alloy Materials?October 30, 2023Titanium alloys are a variety of alloy metals made of titanium and other metals, which are relatively scarce and expensive; titanium alloys are characterized by high strength, light weight, corrosion resistance and high temperature resistance, and can be used in a variety of fine chemicals, which are mainly used in the automotive industry, aerospace, nuclear industry, chemical and petrochemical industries, dentistry and medical restoration and other fields.view

EN

EN

ru

ru