Fasteners are devices that are used to join or hold two or more materials or parts together. There are many types and categories of fasteners, such as screws, bolts, nuts, washers, nails, pins, etc. Among them, rivets are one of the oldest and most widely used fasteners, especially in the fields of construction, automotive, aerospace, and manufacturing. Rivets are metal or plastic pins that have a head at one end and a tail at the other end. They are inserted into pre-drilled or punched holes in the materials or parts to be joined, and then the tail is deformed or broken off to create a second head, forming a permanent joint. Rivets can provide high strength, durability, and reliability for various applications.

However, not all rivets are the same. There are different types and designs of rivets, each with different characteristics and advantages. In this article, we will compare two common types of rivets: pop rivets and blind rivets. We will explain what they are, how they work, what are their pros and cons, and what are their common uses. We will also provide some tips on how to choose the right type of rivet for your project.

Pop rivets and blind rivets are actually the same thing. They are both types of rivets that can be installed from one side of the material or part, without requiring access to or visibility of the other side. This is why they are also called "blind" rivets, because they can be used in "blind" situations, where the back side of the material or part is inaccessible or hidden. Pop rivets and blind rivets are also sometimes referred to as "breakstem" rivets, because they have a stem or mandrel that breaks off during the installation process.

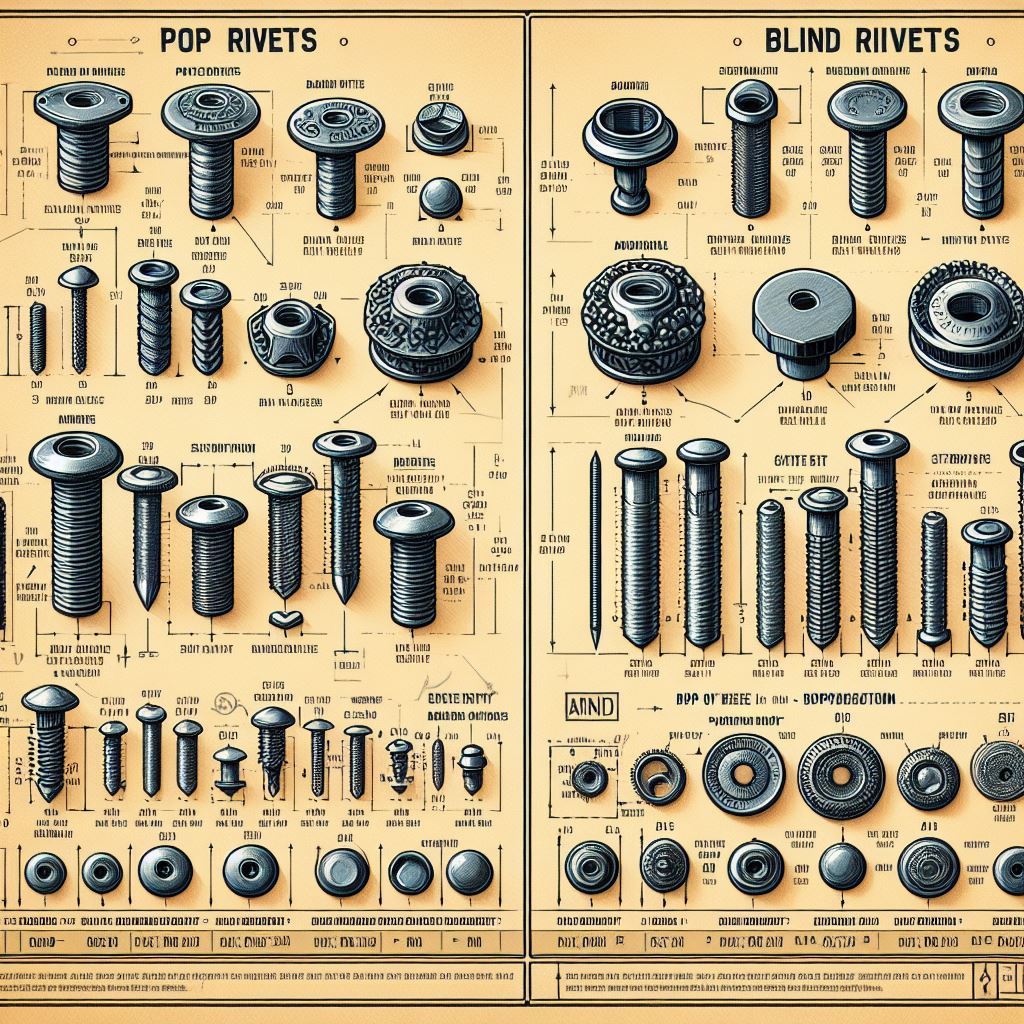

Pop rivets and blind rivets consist of two parts: a rivet body and a mandrel. The rivet body is a hollow metal or plastic tube that has a head at one end and a hole at the other end. The mandrel is a metal or plastic rod that has a head at one end and a tail at the other end. The mandrel is inserted into the hole of the rivet body, and the head of the mandrel is slightly larger than the hole, so that it can hold the rivet body in place.

To install a pop rivet or a blind rivet, you need a special tool called a rivet gun or a riveter. The rivet gun has a nosepiece that can fit the head of the rivet body, and a trigger that can pull the mandrel. The installation process is as follows:

• First, you need to drill or punch a hole in the materials or parts that you want to join. The hole should be slightly larger than the diameter of the rivet body, so that the rivet can fit snugly into the hole.

• Next, you need to insert the rivet into the hole, with the head of the rivet body facing the outside and the head of the mandrel facing the inside. You need to make sure that the rivet is fully inserted into the hole, and that the materials or parts are aligned and clamped together.

• Then, you need to place the nosepiece of the rivet gun over the head of the rivet body, and squeeze the trigger. The rivet gun will pull the mandrel, causing the rivet body to expand and fill the hole. The rivet body will also form a second head on the inside of the material or part, creating a tight and secure joint.

• Finally, you need to release the trigger, and the mandrel will break off at a predetermined point, leaving behind a small stub inside the rivet body. The rivet gun will eject the broken mandrel, and the installation is complete.

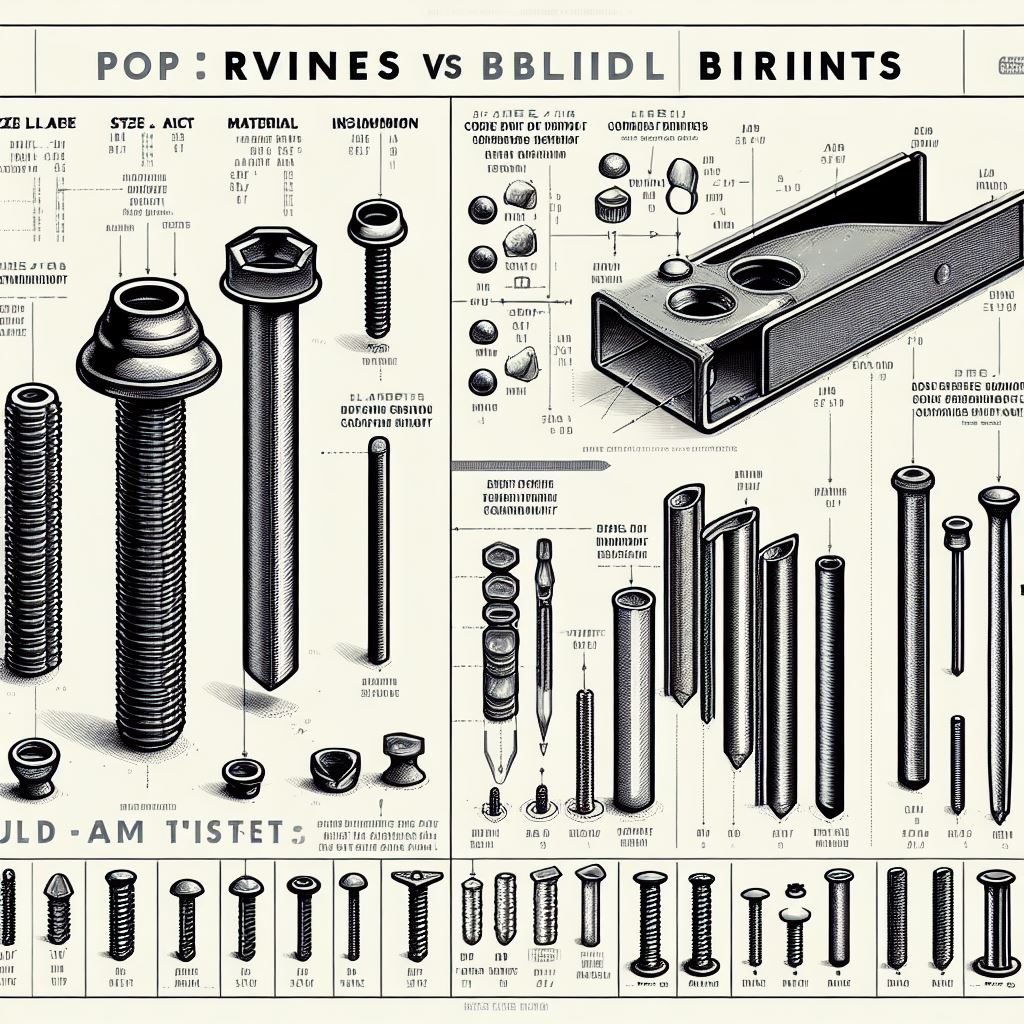

The following image shows a diagram of pop rivets and blind rivets, and how they are installed:

Both pop rivets and blind rivets have their own advantages and disadvantages, depending on their properties and applications. Here are some of the main advantages and disadvantages of pop rivets and blind rivets:

• Advantages: Pop rivets and blind rivets are easy and fast to install, requiring only one tool and one operator. They can be used in a wide range of materials and thicknesses, such as metal, plastic, wood, fiberglass, etc. They can also be used in hard-to-reach or limited-access areas, where other fasteners may not be feasible. Pop rivets and blind rivets can provide a smooth and clean appearance, as they do not protrude from the surface of the material or part. They can also reduce the weight and noise of the joint, as they do not require washers, nuts, or other accessories.

• Disadvantages: Pop rivets and blind rivets are permanent fasteners, meaning that they cannot be easily removed or reused without damaging the material or part. They also require a precise hole size and alignment, as any deviation may cause the rivet to fail or loosen. Pop rivets and blind rivets may not be suitable for applications that require high strength, vibration resistance, or watertightness, as they may not be able to withstand the stress or seal the joint effectively. Pop rivets and blind rivets may also corrode or rust over time, especially if they are made of different metals than the material or part.

The uses of pop rivets and blind rivets depend on their properties and prices. Different rivets are suitable for different fields and industries. Here are some examples of the uses of pop rivets and blind rivets:

• Pop rivets and blind rivets: Due to their versatility and convenience, pop rivets and blind rivets are widely used for various applications, such as construction, automotive, aerospace, marine, electrical, furniture, etc. Some examples of pop rivets and blind rivets products are ducts, panels, cabinets, doors, windows, gutters, signs, lights, etc.

• Pop rivets: Pop rivets are a trademarked brand of blind rivets, owned by Stanley Engineered Fastening. Pop rivets are specially designed to provide a consistent and reliable performance, with a high-quality rivet body and mandrel. Pop rivets are available in various materials, sizes, shapes, and finishes, to suit different needs and preferences. Pop rivets are also compatible with various types of pop rivet guns, which are easy to use and maintain.

• Blind rivets: Blind rivets are a generic term for any type of rivet that can be installed from one side of the material or part. Blind rivets can be further classified into different categories, based on their head shape, body shape, mandrel type, or function. Some of the common types of blind rivets are standard blind rivets, sealed blind rivets, multi-grip rivets, structural rivets, peel rivets, etc. Blind rivets can offer different benefits and features, such as watertightness, vibration resistance, tamper resistance, etc.

The pop rivets and blind rivets are two types of fasteners that can be installed from one side of the material or part, without requiring access to or visibility of the other side. They have the following main differences and advantages:

• Pop rivets and blind rivets consist of two parts: a rivet body and a mandrel. The rivet body is a hollow metal or plastic tube that has a head at one end and a hole at the other end. The mandrel is a metal or plastic rod that has a head at one end and a tail at the other end. The mandrel is inserted into the hole of the rivet body, and the head of the mandrel is slightly larger than the hole, so that it can hold the rivet body in place.

• Pop rivets and blind rivets are installed by using a special tool called a rivet gun or a riveter. The rivet gun has a nosepiece that can fit the head of the rivet body, and a trigger that can pull the mandrel. The rivet gun will pull the mandrel, causing the rivet body to expand and fill the hole. The rivet body will also form a second head on the inside of the material or part, creating a tight and secure joint. The mandrel will then break off at a predetermined point, leaving behind a small stub inside the rivet body. The rivet gun will eject the broken mandrel, and the installation is complete.

• Pop rivets and blind rivets are easy and fast to install, requiring only one tool and one operator. They can be used in a wide range of materials and thicknesses, such as metal, plastic, wood, fiberglass, etc. They can also be used in hard-to-reach or limited-access areas, where other fasteners may not be feasible. Pop rivets and blind rivets can provide a smooth and clean appearance, as they do not protrude from the surface of the material or part. They can also reduce the weight and noise of the joint, as they do not require washers, nuts, or other accessories.

• Pop rivets and blind rivets are permanent fasteners, meaning that they cannot be easily removed or reused without damaging the material or part. They also require a precise hole size and alignment, as any deviation may cause the rivet to fail or loosen. Pop rivets and blind rivets may not be suitable for applications that require high strength, vibration resistance, or watertightness, as they may not be able to withstand the stress or seal the joint effectively. Pop rivets and blind rivets may also corrode or rust over time, especially if they are made of different metals than the material or part.

• Pop rivets and blind rivets are widely used for various applications, such as construction, automotive, aerospace, marine, electrical, furniture, etc. Some examples of pop rivets and blind rivets products are ducts, panels, cabinets, doors, windows, gutters, signs, lights, etc.

• Pop rivets are a trademarked brand of blind rivets, owned by Stanley Engineered Fastening. Pop rivets are specially designed to provide a consistent and reliable performance, with a high-quality rivet body and mandrel. Pop rivets are available in various materials, sizes, shapes, and finishes, to suit different needs and preferences. Pop rivets are also compatible with various types of pop rivet guns, which are easy to use and maintain.

• Blind rivets are a generic term for any type of rivet that can be installed from one side of the material or part. Blind rivets can be further classified into different categories, based on their head shape, body shape, mandrel type, or function. Some of the common types of blind rivets are standard blind rivets, sealed blind rivets, multi-grip rivets, structural rivets, peel rivets, etc. Blind rivets can offer different benefits and features, such as watertightness, vibration resistance, tamper resistance, etc.

If you are looking for a reliable and professional CNC machining service, I recommend you to check out Richconn, a leading custom precision machining factory that can provide you with high-quality pop rivets and blind rivets machining service, as well as other metals and plastics. Richconn has rich experience and advanced equipment to meet your design requirements and application needs. You can visit our website or contact their online customer service for a free quote and consultation. I hope you can find the best solution for your fastener products. blush

Why Motorcycle Parts Using CNC Machining?October 25, 2023Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.view

Why Motorcycle Parts Using CNC Machining?October 25, 2023Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.view What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view

What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view

Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view A Strong Piece - Anodized AluminumOctober 12, 2023Did you know that the oxide layer created when anodizing aluminum is almost as hard as a diamond, making it exceptionally resistant to abrasion? It also provides excellent corrosion resistance.view

A Strong Piece - Anodized AluminumOctober 12, 2023Did you know that the oxide layer created when anodizing aluminum is almost as hard as a diamond, making it exceptionally resistant to abrasion? It also provides excellent corrosion resistance.view Resin Materials: What They Are, How They Differ, and How to Use ThemDecember 8, 2023Resin materials are synthetic or natural substances that can be molded or shaped into various forms. They are widely used in many industries and applications, such as art, crafts, jewelry, furniture, electronics, medical, aerospace, etc.view

Resin Materials: What They Are, How They Differ, and How to Use ThemDecember 8, 2023Resin materials are synthetic or natural substances that can be molded or shaped into various forms. They are widely used in many industries and applications, such as art, crafts, jewelry, furniture, electronics, medical, aerospace, etc.view

EN

EN

ru

ru