Mold products are needed in many industries. Screws and nuts that we use in our daily life, pins and patches used in the electronics industry, equipment housing and internal parts used in the medical industry, and various metal and plastic parts used in the automotive industry are all produced using molds.

In this article, we will introduce the classification of molds, industry trends, and supply chain management. We will provide useful information on how to design, manufacture, produce, and inspect molds. In general, if you are searching for information related to "metal stamping molds," you have come to the right place.

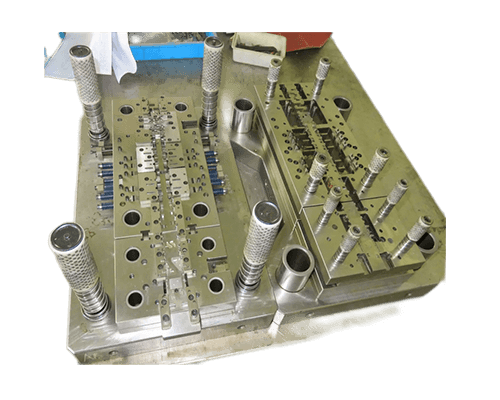

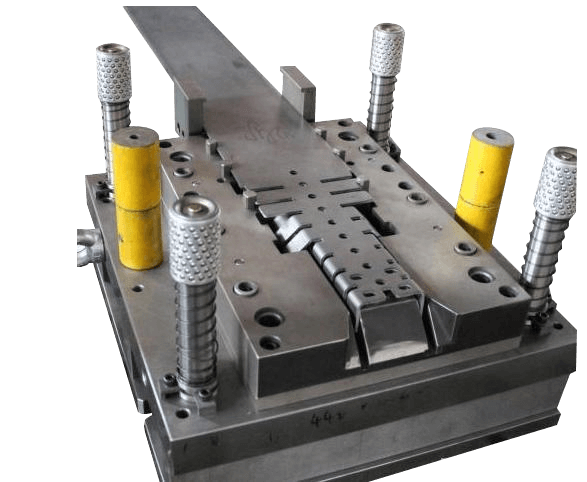

Metal stamping die, also known as punching die, metal mold or metal stamping mold, refers to the pressure processing method of using a die fixed on a stamping press or a pressure machine to apply a certain amount of pressure on a metal or non-metal sheet to cause separation or forming of the material, in order to obtain parts with specific size requirements and qualified appearance quality. There are many types of dies, and here we mainly introduce metal stamping dies.

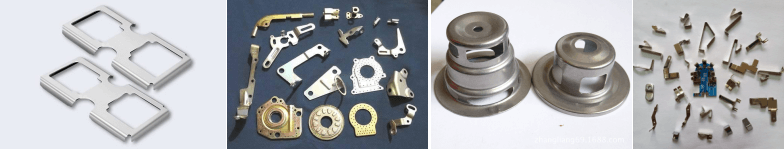

The products processed by the dies have consistent dimensions and appearance. Because they can be quickly formed, the production efficiency is high, the product quality is stable, the precision meets the requirements, the material utilization rate is high, the operation is simple, the labor intensity of the workers is low, and there is no high requirement for the technical skills of the operators.

Metal stamping dies play an important role in the manufacturing industry. They can help manufacturers produce a large number of hardware products efficiently, accurately, and economically. The use of metal stamping dies can reduce production time and costs, improve production efficiency, and ensure that the manufactured products meet specifications and standards. If the production volume is particularly large, it is recommended to use robots or automation equipment to replace manual labor for repetitive tasks, which will further improve efficiency and reduce costs. In addition, metal stamping dies can also produce products of various shapes and sizes to meet the needs of different industries and customers. Due to its importance, metal stamping dies are widely used in modern manufacturing.

The history of stamping dies can be traced back to ancient Egypt around 3000 BC when people used wooden dies to make metal vessels. Over time, people began using materials such as copper, iron, and steel to make dies. In the late 18th and early 19th centuries, with the advent of the Industrial Revolution, stamping dies were widely used, especially in the automotive and aerospace industries. At the beginning of the 20th century, with the emergence of new materials and technologies, the manufacture and use of stamping dies continued to develop. Modern stamping dies are usually made of high-strength alloy steel materials, with higher precision, longer service life, and higher production efficiency. With the development of computer-aided design and manufacturing technology, the design and manufacturing process of stamping dies have become more automated and precise.

The stamping die process is a manufacturing process that shapes and sizes metal sheets into specific shapes. Metal stamping dies can be classified according to different criteria, and here are several common classification methods:

Classification by structure: metal stamping dies can be classified into single-station dies, multi-station dies, compound dies, etc.

Classification by material: metal stamping dies can be classified into steel dies, hard alloy dies, ceramic dies, etc.

Classification by processing method: metal stamping dies can be classified into cold stamping dies, hot stamping dies, precision dies, etc.

Classification by application field: metal stamping dies can be classified into automobile metal stamping dies, electronic metal stamping dies, furniture metal stamping dies, etc.

Classification by processing accuracy: metal stamping dies can be classified into ordinary dies and precision dies.

Design: The first step in the stamping mold process is designing the mold, determining the required shape and size, and considering factors such as material selection, mold structure, and production efficiency.

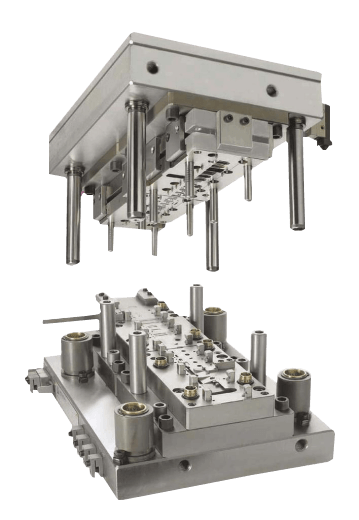

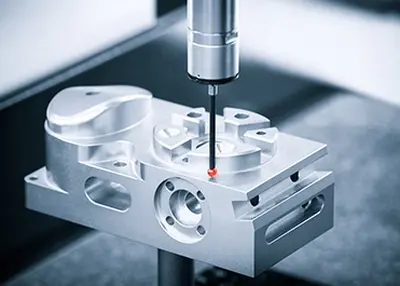

Manufacturing: The stamping mold is manufactured according to the design drawings, usually using high-strength alloy steel materials, and the manufacturing process includes milling, drilling, grinding, and other processes.

Assembly: The punch and die are assembled together to form a complete stamping mold.

Debugging: The stamping mold is debugged, its accuracy and performance are checked, and necessary adjustments and corrections are made.

Production: The metal sheet is placed on the stamping machine, and by the action of the punch and die, the metal sheet is processed into the required shape and size.

Inspection: The processed metal product is inspected to ensure that it meets specifications and standards.

Maintenance: The stamping mold is regularly maintained and serviced to extend its service life and ensure production efficiency and product quality.

The process is implemented through design, manufacturing, assembly, debugging, production, inspection, and maintenance. There is a demand for stamping mold processes because it is a manufacturing process that produces metal products with specific shapes and sizes. The stamping mold works by using a punch and die to shape and cut metal sheets into the desired shape and size.

High production efficiency: Metal stamping molds can produce a large quantity of metal products in a short amount of time, achieving high efficiency production.

Low cost: Compared to other manufacturing processes, metal stamping molds have relatively low costs, effectively reducing production costs.

High precision: Metal stamping molds are manufactured using high-precision equipment, enabling high-precision processing and ensuring product quality.

Wide range of applications: Metal stamping molds can produce metal products of various shapes and sizes, suitable for multiple industries and fields.

High product quality: Metal stamping molds can ensure the consistency of product dimensions, shapes, and surface quality, improving product quality and reliability.

Short production cycle: Compared to other manufacturing processes, the production cycle of metal stamping molds is relatively short, enabling quicker fulfillment of customer demand.

Long service life: Special mold steel is used, providing a longer service life and reducing customer product costs.

Disadvantages of metal stamping molds

Long manufacturing cycle: Metal stamping molds have a longer manufacturing cycle, involving multiple steps such as design, manufacturing, assembly, and debugging, requiring a certain amount of time.

High manufacturing cost: The manufacturing of metal stamping molds requires the use of high-strength alloy steel materials, resulting in high manufacturing costs.

Limited applicability: Metal stamping molds are suitable for producing large quantities of metal products of the same shape and size, and are not ideal for small-batch or multi-variety production.

High maintenance cost: Metal stamping molds require regular maintenance and upkeep, resulting in high maintenance costs.

Difficulty in design: The design of metal stamping molds requires consideration of multiple factors, including material selection, mold structure, and production efficiency, resulting in a high degree of design difficulty.

Inability to adapt to complex product shapes: Metal stamping molds cannot adapt to complex product shapes, requiring the use of other manufacturing processes for such products.

Electronics and appliances: Metal stamping molds can produce various electronic and appliance components, such as plugs, sockets, power plugs, etc.

Automotive industry: Automotive parts, such as car bodies, doors, windows, etc.

Household goods: Household goods, such as locks, doorbells, furniture hardware accessories, etc.

Machinery equipment: Machinery equipment components, such as bearings, gears, couplings, etc.

Communication equipment: Communication equipment components, such as mobile phone shells, antennas, etc.

Medical equipment: Medical equipment components, such as surgical instruments, medical devices, etc.

Lighting fixtures: Lighting fixture components, such as lamp holders, lamp shells, etc.

Hardware industry: Hardware washers, buckles, screws, bolts, etc.

Construction industry: Mesh plates, decorative panels, special-shaped structural components, etc.

Conditions for selecting metal stamping molds

Production quantity: Metal stamping molds are suitable for producing large quantities of identical shaped and sized metal products, so it is necessary to consider whether the production quantity is large enough.

Product shape and size: Metal stamping molds are suitable for producing simple-shaped and uniformly sized metal products, so it is necessary to consider whether the product shape and size are suitable for stamping process.

Manufacturing cost: The manufacturing cost of metal stamping molds is relatively high, so it is necessary to consider whether the production cost can be borne.

Production cycle: The manufacturing cycle of metal stamping molds is relatively long and requires a certain amount of time, so it is necessary to consider whether the production cycle is urgent.

Product quality and precision requirements: Metal stamping molds can achieve high-precision processing, ensuring consistency in product size, shape, and surface quality, so it is necessary to consider whether the product quality and precision requirements are high.

Design difficulty: The design of metal stamping molds needs to consider multiple factors, including material selection, mold structure, and production efficiency, so it is necessary to consider whether the design difficulty is high.

Metal stamping molds suitable for your needs

Production quantity: Metal stamping molds are suitable for producing large quantities of identical shaped and sized metal products, so it is necessary to consider whether the production quantity is large enough.

Product shape and size: Metal stamping molds are suitable for producing simple-shaped and uniformly sized metal products, so it is necessary to consider whether the product shape and size are suitable for stamping process.

Manufacturing cost: The manufacturing cost of metal stamping molds is relatively high, so it is necessary to consider whether the production cost can be borne.

Production cycle: The manufacturing cycle of metal stamping molds is relatively long and requires a certain amount of time, so it is necessary to consider whether the production cycle is urgent.

Product quality and precision requirements: Metal stamping molds can achieve high-precision processing, ensuring consistency in product size, shape, and surface quality, so it is necessary to consider whether the product quality and precision requirements are high.

Design difficulty: The design of metal stamping molds needs to consider multiple factors, including material selection, mold structure, and production efficiency, so it is necessary to consider whether the design difficulty is high.

Comprehensive factors: including industrial chain costs, infrastructure costs, and other factors.

Supply Chain Status of Metal Stamping Molds Manufacturing

Overview of Industry Demand Chain: Due to the concentration of the application industries for metal stamping molds, the entire industry, from the material end to the manufacturing end, is mainly concentrated in the Guangdong region of China. The demand side is more reflected in the sales of finished products. In particular, molds for industries such as electronics, lighting, and communication equipment are more concentrated in the Humen area of Dongguan.

Overview of Manufacturing Capability: With the migration of manufacturing industries, China, known as the "world's factory," has basically completed the manufacturing of metal stamping molds in the Dongguan region of Shenzhen, and then distributed them to contract manufacturing companies such as "Foxconn," "BYD," and "Lite-On Precision" to produce electronic products and automotive parts.

Overview of Supporting Supply Chain: In China, the industrial chain for designing, material sourcing, and manufacturing metal stamping molds is highly developed and complete, and it also concentrates most of the industry's engineers and manufacturing equipment. The supporting supply chain is quite complete.

Overview of the Entire Supply Chain: The high concentration of the industry and talent results in a highly efficient overall supply chain. A simple continuous stamping mold can be produced in Humen within 10 days. The highly competitive and concentrated industry also makes the entire supply chain very complete, so choosing to manufacture your metal stamping molds in Guangdong should be the right choice.

Today's market competition is becoming increasingly fierce. In order to stand undefeated in the market, companies need to continuously improve their competitiveness. As a China CNC machining service provider, we are proud to announce that we can provide high-quality services including 5-axis CNC service, CNC surface finish, and CNC polypropylene to customers in the metal, electronics, aviation, and aerospace industries, and make customers satisfied.

We have a professional design team that has rich design experience and innovation consciousness and can provide design solutions that meet market demand according to customers' needs and requirements. At the same time, we also have high-performance equipment and advanced technical capabilities to ensure product quality and production efficiency, so that customers can get a better service experience.

Our engineering team has extensive experience and can timely identify and solve problems in the production process to ensure product quality stability. In addition, we have established a complete supply chain system, which can ensure timely supply of raw materials and inventory management, so as to better control costs and improve efficiency.

Most importantly, we provide centralized one-stop services, which can provide customers with comprehensive support from design, production to after-sales service. Customers only need one phone call or one email to enjoy our professional services.

In summary, we firmly believe that service is the core of enterprise development. We will continue to provide high-quality services to customers, make customers satisfied, and make the enterprise stand undefeated in the market.

Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view

Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view CNC Machining Aerospace Parts: The Manufacturing Key to High-precision EngineeringSeptember 22, 2023As an avid fan of aerospace technology, I'm excited to take you into the world of CNC machining of aerospace parts, where precision meets innovation.view

CNC Machining Aerospace Parts: The Manufacturing Key to High-precision EngineeringSeptember 22, 2023As an avid fan of aerospace technology, I'm excited to take you into the world of CNC machining of aerospace parts, where precision meets innovation.view The Brief Introduction to 5 Axis CNC MachineAugust 22, 2023Over the past few years, CNC machining technology has advanced from basic machine tools to more complex ones. Nowadays one of the most cutting-edge techniques accessible is 5-axis CNC machining. It us...view

The Brief Introduction to 5 Axis CNC MachineAugust 22, 2023Over the past few years, CNC machining technology has advanced from basic machine tools to more complex ones. Nowadays one of the most cutting-edge techniques accessible is 5-axis CNC machining. It us...view How long does it take to CNC machine a simple part?November 1, 2023CNC machining, as an important process in the modern manufacturing field, has been widely used in various industries to realize the manufacturing of precision parts through the intelligent control of computers. In the manufacturing process, the complexity of the part has a great impact on the machining time. In this paper, we will discuss the time required for CNC machining from the perspective of simple geometry to highly complex structures, and analyze in depth the influence of geometry, machining process and related parameters on machining time.view

How long does it take to CNC machine a simple part?November 1, 2023CNC machining, as an important process in the modern manufacturing field, has been widely used in various industries to realize the manufacturing of precision parts through the intelligent control of computers. In the manufacturing process, the complexity of the part has a great impact on the machining time. In this paper, we will discuss the time required for CNC machining from the perspective of simple geometry to highly complex structures, and analyze in depth the influence of geometry, machining process and related parameters on machining time.view Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view

Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view

Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view