As the world's leading rapid prototyping companies, we have added Aluminum 5083-H111 (3.3547 or AlMg4.5Mn0.7) to our line of more than 40 in-stock metals and plastics materials for quick turnaround CNC service. This material is often used in extreme environments, as its high magnesium content makes it very resistant to salt water and industrial chemicals.

It is also one of the strongest heat-treated aluminum alloys available, with a good strength-to-weight ratio. It is also weldable, making it ideal for shipping and automotive applications.

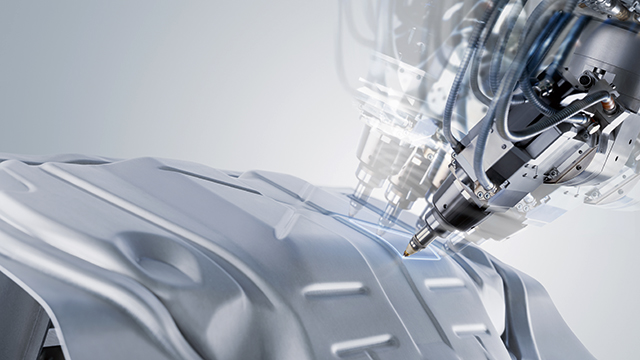

Designers simply upload a CAD file to our online portal, select the material and specify a preferred shipping timeframe, choosing either fast 1 to 3 days for standard manufacturing or a flexible 7 to 12 day option. The engineer then receives a quote that includes a feasibility analysis of the 3D design. Since the feasibility is modeled at the time the quote is accepted, we assign the machine and ship the part on time.

By adding this versatile aluminum alloy to our line of stock materials, our customers have more choices in CNC Machining services, whether they need rapid prototyping parts or low-volume end-use parts.

The choice of material for a component depends on its application and desired properties. By adding this aluminum alloy to our line of stock materials, we are providing our customers with a metal that has a good strength-to-weight ratio, is cost-effective, and can operate in harsh environmental conditions. In particular, it offers the potential for faster production times compared to many other suppliers.

Our CNC machining materials include many grades of plastics (ABS, acetal, polycarbonate, nylon and PEEK) and metal alloys (brass, copper, titanium, select stainless steels and aluminum). Our compact CNC material selector is a practical reference to help designers choose the right plastic or metal material for their needs. The selector lists specific material properties such as heat resistance, tensile strength, and hardness to choose the best material for the part application, and includes information on CNC milling and CNC turning suitability.

Understanding and Improving Modern CNC MillingOctober 11, 2023CNC MillingCNC milling has been around for more than 50 years, but the technology continues to evolve. Recent advances have made it possible to automate the entire process, from design to finished par...view

Understanding and Improving Modern CNC MillingOctober 11, 2023CNC MillingCNC milling has been around for more than 50 years, but the technology continues to evolve. Recent advances have made it possible to automate the entire process, from design to finished par...view Extrusion Blow Molding: A Guide to the Process, Materials, and ApplicationsDecember 5, 2023Extrusion blow molding is a process of forming hollow plastic parts by extruding a molten tube of polymer and inflating it with air inside a mold. It is one of the most common and versatile methods of producing plastic containers, such as bottles, jars, jugs, and drums.view

Extrusion Blow Molding: A Guide to the Process, Materials, and ApplicationsDecember 5, 2023Extrusion blow molding is a process of forming hollow plastic parts by extruding a molten tube of polymer and inflating it with air inside a mold. It is one of the most common and versatile methods of producing plastic containers, such as bottles, jars, jugs, and drums.view CNC Motion Control and Three Common TypesOctober 20, 2023Many CNC machines can be left unattended throughout the machining cycle, freeing the operator for other tasks. This benefit allows CNC users to provide several side effects, including reduced operator fatigue, errors due to operator error, and consistent and predictable machining times for each workpiece.view

CNC Motion Control and Three Common TypesOctober 20, 2023Many CNC machines can be left unattended throughout the machining cycle, freeing the operator for other tasks. This benefit allows CNC users to provide several side effects, including reduced operator fatigue, errors due to operator error, and consistent and predictable machining times for each workpiece.view Unlocking the Brilliance of Machined Face WheelsNovember 8, 2023Are you ready to elevate your vehicle's style and performance to a whole new level? Look no further! In this comprehensive guide, I'll take you on an exciting journey to explore the world of machined face wheels. From understanding what they are to discovering their stunning aesthetics, identifying suitable vehicle models, and even delving into the intricacies of installation and maintenance, we've got it all covered.view

Unlocking the Brilliance of Machined Face WheelsNovember 8, 2023Are you ready to elevate your vehicle's style and performance to a whole new level? Look no further! In this comprehensive guide, I'll take you on an exciting journey to explore the world of machined face wheels. From understanding what they are to discovering their stunning aesthetics, identifying suitable vehicle models, and even delving into the intricacies of installation and maintenance, we've got it all covered.view 4 Surface Finishing Techniques in the Orthopedic Medical IndustryOctober 26, 2023With the development and advancement of science and technology and the innovation of mechanical parts processing technology, the society has put forward more stringent requirements for medical devices in terms of deburring and polishing surface accuracy, surface asepticization, and compatibility with implanted materials.view

4 Surface Finishing Techniques in the Orthopedic Medical IndustryOctober 26, 2023With the development and advancement of science and technology and the innovation of mechanical parts processing technology, the society has put forward more stringent requirements for medical devices in terms of deburring and polishing surface accuracy, surface asepticization, and compatibility with implanted materials.view Sheet Metal Thickness Conversion Chart: Galvanized Steel, Stainless Steel, AluminumDecember 5, 2023In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.view

Sheet Metal Thickness Conversion Chart: Galvanized Steel, Stainless Steel, AluminumDecember 5, 2023In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.view

EN

EN

ru

ru