The whole process of processing, in the selection of the appropriate processing method CNC processing or 3D printing, after the completion of processing, most of them need surface treatment. Meet the corrosion resistance, abrasion resistance, decoration or other special functional requirements of the product.

Processing surface finishing process has dozens of kinds, as a large-scale processing plant can provide processing of the vast majority of surface finishing process requirements, and there is a standardized production production process.

Surface painting is one of the most widely used surface processes. Spray painting has the following advantages:

(1) It can cover the surface defects of the workpiece after molding;

(2) Through spraying can obtain a variety of colors, different gloss, different appearance of the visual effect and a variety of different feel;

(3) Enhance the hardness and scratch resistance of the surface of the workpiece;

(4) The effects of spraying are: matte, semi-matte, high-gloss, various colors, various textures, etching, brushed effect, leather effect, elastic feel effect (rubber paint) and so on.

Sandpaper sanding can be carried out by hand, you can also use the belt sander equipment, is the most commonly used 3D printing parts post-polishing, the most widely used technology.

Sandpaper sanding should be careful when dealing with relatively small parts, because it relies on manual or mechanical reciprocating motion.

If the part has the minimum requirements of precision and durability, do not over-sand, and calculate how much material to sand away, otherwise over-sanding will deform the part and scrap it.

Polishing is based on the use of flexible polishing tools and abrasive particles, or other polishing media on the surface of the workpiece surface modification process.

Polishing can not improve the dimensional accuracy or geometric precision of the workpiece, but to smooth the surface or mirror luster for the purpose, and sometimes also used to eliminate the gloss.

After the polishing process of the workpiece surface roughness generally up to Ra0.63 ~ 0.01 micron. PMMA transparent workpiece because of the need for very high grinding and polishing requirements, so the price of PMMA transparent parts is relatively expensive.

Sandblasting is the use of compressed air as a driving force to form a high-speed jet beam will be sprayed at high speed to the surface of the workpiece process.

The process can make the workpiece to obtain a certain degree of cleanliness and different roughness, the mechanical properties of the surface of the workpiece has been improved to increase the adhesion between the workpiece and the paint coating, extending the durability of the paint film, but also conducive to the leveling of paint and decoration.

Sandblasting can be processed in about 5 to 10 minutes, and the surface of the treated product is smooth with a uniform matte effect.

The blast media are usually very small, finely ground thermoplastic particles. They are relatively durable and can be sprayed over a range of light to severe abrasions.

Screen printing is a type of printing in which a design is applied to the desired area. The screen board is framed with a border, then the screen is hollowed out with the pattern to be silk-screened, the dye is applied to the screen, and finally the dye is scraped with a squeegee into the hollowed-out pattern, and then the silk-screening is completed.

General product text or logo will use silkscreen. Common products that require screen printing include electrical appliances, toys, and household items. Silkscreen can only be used for flat products, so uneven and curved products cannot be silkscreened.

3D printed parts are impregnated in a steam tank with liquid at the bottom that has reached boiling point. The steam rises and melts a layer of about 2 microns on the surface of the part, making it smooth and shiny in seconds.

Vapor smoothing is widely used in consumer electronics, prototyping and medical applications. The method has a low impact on accuracy, with the disadvantage that it has size limitations and doesn't work very well on products printed on highly heat-resistant materials.

If your parts need surface finishing process, you can choose Richconn, Richconn was founded in 2008, with 16 years of experience in metal surface treatment, we can provide you with a variety of surface finishing services, such as Anodizing Service, PVD Coating Service, Plating Service, Black Oxide Services and so on, choose the right surface finishing method for your CNC machined parts.

During the machining process, choosing the right machining method, such as CNC machining or 3D printing, is critical to the quality of the final product. However, after machining, we usually need surface treatment to meet the special needs of the product, including corrosion resistance, abrasion resistance, and decorative properties. Different products are suitable for different surface treatment processes. When selecting a surface treatment process, the specific needs of the product and the desired effect should be considered. Different processes offer different characteristics to meet the requirements of different products. Therefore, choosing the right surface treatment process is an important step in the process to ensure the quality of the final product.

Understanding the Properties of Anodizing Process in One ReadingApril 4, 2023Nowadays, the use of metal technology is quite popular, and many machines in the market have large metal parts. One of the surface treatment processes for metal is anodizing, which is very commonly us...view

Understanding the Properties of Anodizing Process in One ReadingApril 4, 2023Nowadays, the use of metal technology is quite popular, and many machines in the market have large metal parts. One of the surface treatment processes for metal is anodizing, which is very commonly us...view CNC Software: The Key to Efficient Machining ProcessesJuly 5, 2024CNC software plays a pivotal role in optimizing machining processes by enabling precise control over automated tools. Let’s discover the world of CNC machining: principles, software, benefits, and selection tips.view

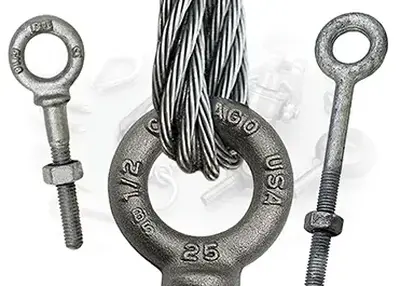

CNC Software: The Key to Efficient Machining ProcessesJuly 5, 2024CNC software plays a pivotal role in optimizing machining processes by enabling precise control over automated tools. Let’s discover the world of CNC machining: principles, software, benefits, and selection tips.view Machined Eye Bolts: Your Ultimate Guide to Quality and SafetyNovember 9, 2023When it comes to precision engineering and safety, there's no room for compromise. Whether you are involved in industrial operations, construction, aerospace, or recreational equipment, the quality of your components is paramount. Enter Machined Eye Bolts, the unsung heroes that bear the weight of your projects, ensuring safety and performance.view

Machined Eye Bolts: Your Ultimate Guide to Quality and SafetyNovember 9, 2023When it comes to precision engineering and safety, there's no room for compromise. Whether you are involved in industrial operations, construction, aerospace, or recreational equipment, the quality of your components is paramount. Enter Machined Eye Bolts, the unsung heroes that bear the weight of your projects, ensuring safety and performance.view How to Produce High-quality Parts With CNC?June 25, 2024The passage mainly talks about the production progress of high-quality parts with the help of CNC. It’s strongly recommended that Richconn is an effective company, which owns many technicians and advanced technology.view

How to Produce High-quality Parts With CNC?June 25, 2024The passage mainly talks about the production progress of high-quality parts with the help of CNC. It’s strongly recommended that Richconn is an effective company, which owns many technicians and advanced technology.view Advantages of Aluminum for CNCOctober 13, 2023Aluminum is very dimensionally stable, so you can cut away a lot of it and still keep the residual stress within limits. Using carbide tools and modern coolants will give you an excellent finish. For a matte finish, you can bead blast the parts or anodizing them for a uniform aesthetic finish and added corrosion resistance.view

Advantages of Aluminum for CNCOctober 13, 2023Aluminum is very dimensionally stable, so you can cut away a lot of it and still keep the residual stress within limits. Using carbide tools and modern coolants will give you an excellent finish. For a matte finish, you can bead blast the parts or anodizing them for a uniform aesthetic finish and added corrosion resistance.view The Complete Guide to Aerospace Fasteners 2023August 24, 2023The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of ai...view

The Complete Guide to Aerospace Fasteners 2023August 24, 2023The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of ai...view

EN

EN

ru

ru