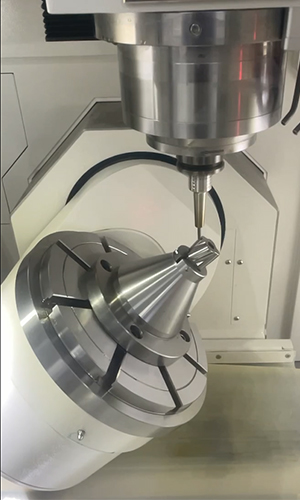

With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture high-precision impellers. 5-axis machining centers have been widely used in impeller manufacturing due to their advantages of high precision, high efficiency, and strong adaptability.

As a leading China 5-axis CNC machining supplier, Richconn is going to introduce the application of 5-axis machining centres in the production of high-speed blower impellers, with a focus on the manufacturing process, process optimization, and advantages of 5-axis machining centers.

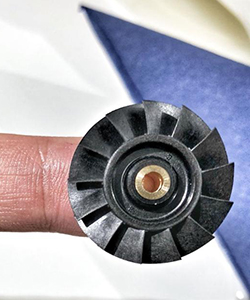

As an example, we will take the impeller of the Dyson hair dryer as a case study. The impeller of the Dyson hair dryer is made of aluminium alloy, and its shape is complex with high precision requirements. The use of traditional manufacturing methods such as casting and forging is difficult to meet the requirements of impeller accuracy and efficiency.

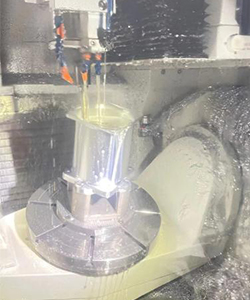

Compared with traditional methods, the application of 5-axis machining centers can greatly improve the processing efficiency and accuracy. In the impeller manufacturing process, the five-axis machining can complete the processing of the impeller in one clamping, greatly reducing the number of clamping and positioning, and improving the processing accuracy and efficiency. In addition, the 5-axis machining center has the advantages of high-speed cutting, which can effectively reduce the machining time and improve the production efficiency.

In the process of impeller manufacturing, the optimization of processing technology is also very important. By optimizing the tool path, cutting parameters, and tool selection, processing efficiency and accuracy can be further improved. The 5-axis machining center has strong adaptability to the optimization of processing technology, which can effectively improve the processing quality and reduce the processing time.

In terms of performance, the impeller processed by the 5-axis machining center has high precision and good balance, which greatly improves the performance and efficiency of the blower. The accuracy level of the impeller processed by the 5-axis machining center can reach IT7, and the processing time can be reduced by more than 50% compared with traditional methods. These data fully demonstrate the advantages of 5-axis machining centres in impeller manufacturing.

In conclusion, the application of 5-axis processing in the manufacturing of high-speed blower impellers can greatly improve the processing efficiency and accuracy, and optimize the processing technology, thereby improving the performance and efficiency of the blowers. With the continuous development of technology, the application of 5-axis machining centers in impeller manufacturing will become more extensive, and will play a greater role in promoting the development of the industry.

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view

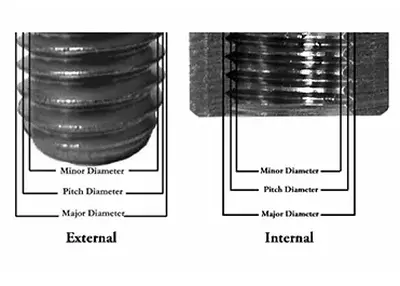

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view Exploring the Precision and Efficiency of CNC Tapping in MachiningNovember 22, 2023Precision in machining isn't just a goal; it's the essence that defines excellence. Within this realm, CNC tapping emerges as a beacon of accuracy, revolutionizing how threads are crafted and machines function. Let's delve deeper into this intricate world to uncover the precision and efficiency it offers.view

Exploring the Precision and Efficiency of CNC Tapping in MachiningNovember 22, 2023Precision in machining isn't just a goal; it's the essence that defines excellence. Within this realm, CNC tapping emerges as a beacon of accuracy, revolutionizing how threads are crafted and machines function. Let's delve deeper into this intricate world to uncover the precision and efficiency it offers.view UNF Threads vs UNC Threads and What Are UNF Threads and UNC ThreadsNovember 17, 2023In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.view

UNF Threads vs UNC Threads and What Are UNF Threads and UNC ThreadsNovember 17, 2023In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.view What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view

What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view

Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view Why Motorcycle Parts Using CNC Machining?October 25, 2023Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.view

Why Motorcycle Parts Using CNC Machining?October 25, 2023Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.view

EN

EN

ru

ru