Manufacturers now view outsourcing not just as a supplier relationship, but as a partnership. Lei Sheng, product manager at Richconn, explains why outsourcing projects with reliable partners make sense.

Many manufacturers face the challenge of capacity to meet production demand, especially with increasing time pressure. When internal resources are stretched, outsourcing can be the solution.

Manufacturers often have multiple obligations. First, they must manage their daily operations, which involves standardized routine processes. These processes usually need to be managed predictably, meaning orders must be completed within the timeframes offered and customer expectations must be met. In addition, there are short-term challenges. These arise when routines are interrupted because there is insufficient capacity to handle the increased workload - often caused by an unforeseen surge in demand or a rush or special order. During these phases, manufacturers need an outsourcing solution to help them deliver their orders on time.

An outsourced "partner" can be viewed as an extension of the customer's production facilities, with significantly lower costs and minimal risk. Once a product or part design is complete, manufacturers can rely on their outsource partner for repeatability of production. Whether it's a small engineering firm needing ad hoc support or for a larger manufacturer requiring a substantial or preferred supplier relationship, collaborative outsourcing can be the optimal solution.

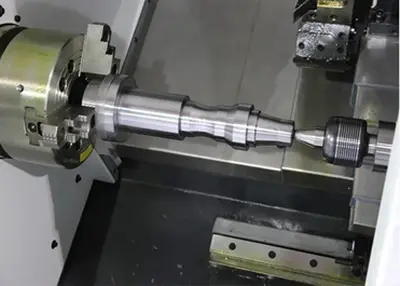

Outsourcing provides the flexibility to meet unexpected demand for parts or prototypes with 3d printing service, cnc machining services and injection molding. By outsourcing 3D printing to quickly create and compare complex parts, design adjustments can be made easily. With CNC machining or injection molding, quantities are produced in small to medium runs in days. Outsourcing provides on-demand services and rapid delivery capabilities that give manufacturers a competitive edge - backed by design for manufacturability analysis and expert technical advice.

-640x360_tcm27-98897.jpg)

Outsourcing is most effective when both the customer and the outsourcing partner use integrated online systems. These systems are essential for ensuring bilateral data flow and complete job management from start to finish.

Customer data protection is an important component of a successful outsourcing partnership. Outsourcing to a third party at any stage of the supply chain requires a high level of trust, especially when it comes to breakthrough technologies. Industries such as aerospace or automotive and medical require absolute secrecy. A close, trusting working relationship with the outsourcing partner is necessary when rapid prototyping is required to commercialize a new product. After all, the manufacturer and the outsourcing partner share the same goal: achieving business benchmarks within the set timeframe without compromising quality and confidentiality.

Richconn recognizes that flexibility and adaptability are increasingly important in providing services to manufacturers, particularly in engineering and technology-related industries. As a result, prototyping and demand-driven manufacturing tasks are outsourced to partners that offer an effective combination of technology, process management and expertise. Along with these come other key benefits, such as consistent quality, reliability and fast delivery times. Companies outsourcing work to Richconn are supported by 24*7 hours service capabilities, which offer real-time feasibility analysis in parallel - including material specifications and quantities. Because the design and production phases are seamlessly linked via our proprietary software, orders can be completed in a matter of days.

Using on-demand production capabilities, Richconn produces prototypes and parts for final use. In terms of speed and scale of production, we can keep pace with changing manufacturer requirements. We believe that successful outsourcing is based on a simple formula: The partnership must be optimal and precise to the customer's needs for each order.

Spot Welder 101: In-Depth Guide of Process and Tips RevealedJanuary 2, 2024What's a spot welder? The article gives you a comprehensive guide to spot welders and shows you how to control spot welders effectively.view

Spot Welder 101: In-Depth Guide of Process and Tips RevealedJanuary 2, 2024What's a spot welder? The article gives you a comprehensive guide to spot welders and shows you how to control spot welders effectively.view Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view

Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view How to Maximize the Effectiveness of CNC Machining Technology?August 14, 2023Positive Innovation of Mechanical CNC Machining EquipmentIn order to maximize the application effect of CNC machining technology, it is necessary to analyze the characteristics of CNC machining ODM te...view

How to Maximize the Effectiveness of CNC Machining Technology?August 14, 2023Positive Innovation of Mechanical CNC Machining EquipmentIn order to maximize the application effect of CNC machining technology, it is necessary to analyze the characteristics of CNC machining ODM te...view Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view

Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view

Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view How Do I Get the Part to Meet the Machining Conditions?October 30, 2023Featuring intricate geometries, often complex CNC parts may require the machining of a series of contours, holes, and recesses to achieve the desired shape and size. Read on to learn more about the complexity of CNC machined part geometries and some of our best tips for reducing design complexity.view

How Do I Get the Part to Meet the Machining Conditions?October 30, 2023Featuring intricate geometries, often complex CNC parts may require the machining of a series of contours, holes, and recesses to achieve the desired shape and size. Read on to learn more about the complexity of CNC machined part geometries and some of our best tips for reducing design complexity.view

EN

EN

ru

ru