Time to market is critical to your competitive advantage. However, forgoing prototyping is a big risk that can cost you production costs, lost revenue, and your reputation if your product doesn't work. Here, we take a quick look at the different rapid prototyping options available and when they might be right for your next development project.

Exactly which prototyping technology you choose depends on what stage of the product development cycle you're at. In the beginning, you may only need a prototype to present an idea for preliminary approval, but as the development process progresses, you'll need to consider form, function, performance and ease of manufacturing in production.

Smart manufacturers will always keep the end product in mind. Rapid prototyping aims to refine the design and functionality, test it in the field, and ensure compliance. Sometimes you may even want to test the new product before deciding on final mass production. At this point, the lines between low-volume production and prototyping begin to blur.

Of course, there are many reasons for prototyping, and often multiple iterations and different technologies are required as you move through each stage of development. The fact is that rapid prototyping has evolved over the years and become faster and faster.

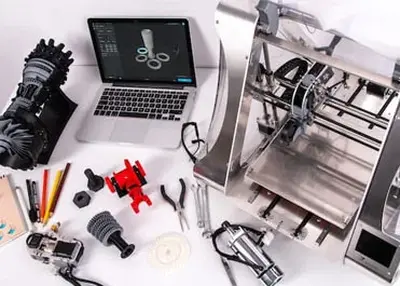

Many people think of 3D printing when they think of rapid prototyping, and it is indeed a commonly used technology. It is now even used for small batch production. But 3D printing is not the only process used for prototyping.

At Richconn, for example, we use:

- MultiJet Fusion (MJF)

- Selective Laser Sintering (SLS)

- Stereolithography

- Direct metal laser sintering

- PolyJet

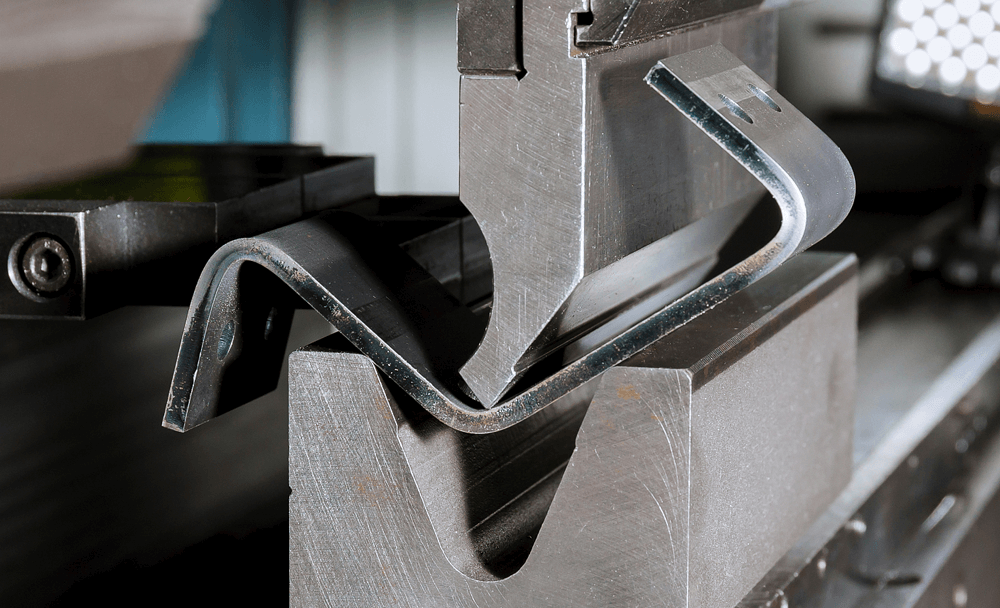

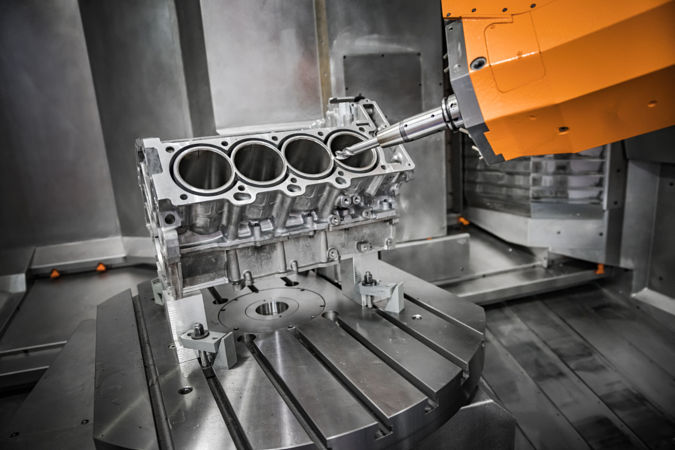

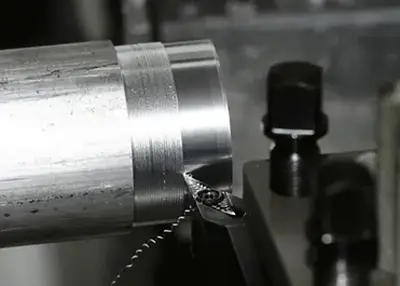

- CNC machining manufacturing

- Injection molding

The first five processes are additive manufacturing technologies, and we are always looking to expand this list. The last two are clearly different types of manufacturing processes - but both offer different options for rapid prototyping.

The early stages of a project typically include concept development, initial design and product validation, and some testing to verify aesthetics and functionality. This is where speed of delivery is critical, and fast 3d prints may well be your chosen option - but it's not a final choice. Even within the world of additive manufacturing, there are different technologies, each offering different options at different price points. In the end, it pays to work with a rapid prototyping companies that offers you a wide range of choices and good advice.

Typically, you'll need between one and five parts for an initial prototype concept, so 3D printing or CNC machining is the best choice. If your needs run into the hundreds, you can also consider rapid injection molding.

Each of the manufacturing technologies represents a tradeoff, and you'll need to think about the speed, cost and information content you need in the initial stages. For example, you may need to prototype a part using 3D printing , but you need to have in mind how it will be manufactured. This may require a technology change at a later stage so that the same material and manufacturing process can be used for the pre-production prototypes.

Once the prototypes have been validated for fit, form, function and aesthetics, feasibility must be optimized. At this point, the design of the final manufacturing process begins.

For injection molding, you may want to optimize prototype designs so you can produce molds faster or more cost-effectively. Similarly, you will want to achieve optimum moldability. A good example is changing the draft of a mold, which can lead to significant improvements in part ejection to improve surface quality and blow count.

In practice, a supplier will help you design a tool and suggest changes to make it work or improve its design. At Richconn, we have automated this process so that once you upload your injection molding CAD data, you will receive a quote and a design for feasibility analysis within a few hours.

But beyond that, it also makes sense to produce prototypes using the same process as the final products. And when you work with injection molding, you don't need to wait the 10-12 weeks that is usual for tools made of steel. Using aluminum tooling makes this process "fast" and can deliver parts in just a few days.

Even better, if you design your mold carefully, you can modify it to optimize your production parts - it's best to consult your supplier at this point.

Another advantage of rapid injection molding is that it eases the transition from prototyping to low-volume production. If you only need up to 50,000 parts, you may not need more. Alternatively, it can serve as a bridge to volume production, providing you with parts until your final steel tool is ready.

Finally, rapid injection molding allows you to test the market and, if necessary, revise your design before committing.

Most importantly, this phase of prototyping or low-volume production helps validate the production process quickly and cost-effectively, which is also possible for prototypes with CNC machining or one of the various additive manufacturing processes.

There are no hard and fast rules for prototyping in product development, but you shouldn't skip it. Exactly what you need and when depends on your individual requirements. It's best to contact a provider who offers a wide range of technologies and can support you throughout the process and, if necessary, all the way to the first series.

Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view

Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view Navigating Internal Turning vs External TurningNovember 22, 2023Welcome to the world of precision engineering, where every turn counts. As a CNC machining enthusiast, I invite you on a journey to uncover the subtleties between internal turning and external turning - two pivotal techniques shaping the art of machining.view

Navigating Internal Turning vs External TurningNovember 22, 2023Welcome to the world of precision engineering, where every turn counts. As a CNC machining enthusiast, I invite you on a journey to uncover the subtleties between internal turning and external turning - two pivotal techniques shaping the art of machining.view Electrophoresis Metal Coating in Laboratory AutomationFebruary 29, 2024Navigating Precision in Laboratory AutomationIn the dynamic landscape of scientific research, the central axis of efficiency revolves around laboratory automation. At the nucleus of this efficiency li...view

Electrophoresis Metal Coating in Laboratory AutomationFebruary 29, 2024Navigating Precision in Laboratory AutomationIn the dynamic landscape of scientific research, the central axis of efficiency revolves around laboratory automation. At the nucleus of this efficiency li...view How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view

How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view How Much Do 3D Prints Cost: An In-Depth Guide to ExpensesAugust 15, 20233D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arise...view

How Much Do 3D Prints Cost: An In-Depth Guide to ExpensesAugust 15, 20233D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arise...view Understanding and Improving Modern CNC MillingOctober 11, 2023CNC MillingCNC milling has been around for more than 50 years, but the technology continues to evolve. Recent advances have made it possible to automate the entire process, from design to finished par...view

Understanding and Improving Modern CNC MillingOctober 11, 2023CNC MillingCNC milling has been around for more than 50 years, but the technology continues to evolve. Recent advances have made it possible to automate the entire process, from design to finished par...view

EN

EN

ru

ru