Machining processes are a key manufacturing method used to transform raw materials into desired parts and products. These processes include milling, turning, drilling, grinding, reaming, stamping, forging, injection molding, EDM, heat treatment, welding, stretch molding, powder metallurgy and 3D printing. The following are some common machining processes:

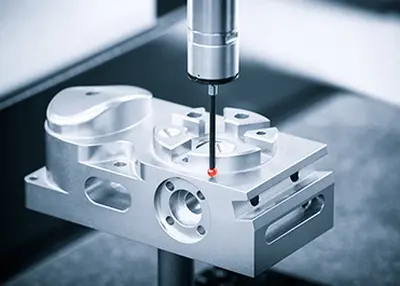

Milling is a common machining process that creates flat surfaces or fabricates complex geometries by rotating a tool on a workpiece to remove material. Milling can be categorized into CNC Milling and Manual Milling.

CNC Milling: In CNC milling, a computer program controls the movement of the tool to precisely cut the workpiece. This method offers a high degree of accuracy and repeatability and is suitable for the manufacture of complex parts.

Manual Milling: Manual milling usually requires the operator to manually control the milling machine. Although accuracy is affected by the skill of the operator, it is suitable for simple tasks. Milling machine, mainly through the rotating tool on the workpiece fixed in the workpiece table for processing, suitable for processing flat surfaces, grooves, various curved surfaces or gears.

Turning is a process used for rotationally symmetrical parts by rotating the workpiece and moving the tool along the workpiece axis to remove material and create the desired shape. Turning can be categorized into CNC Turning and Manual Turning.

CNC Turning: In a CNC lathe, a computer program controls the movement of the tool to precisely cut along the axis of rotation of the workpiece. This method is ideal for manufacturing axisymmetric parts with high accuracy and efficiency.

Manual Turning: Manual turning requires the operator to manually control the lathe. Although not as fast or accurate as CNC turning, it is still useful for specific applications. Lathe, mainly through the turning tool on the rotating workpiece for linear or curved translational movement processing, suitable for processing shafts and rotary parts.

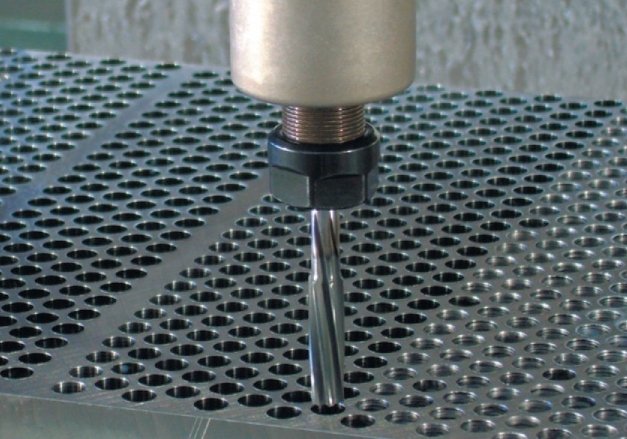

Drilling is the process of creating holes or apertures in a workpiece. It is usually performed using a drill. This process is used in the manufacture of a wide variety of products, including mechanical parts, building structures, and electronic equipment.

Grinding is a process used to accurately remove material and obtain high precision surface quality. It is commonly used in the manufacture of high-precision parts, such as in the aerospace and automotive industries. Grinding uses grinding wheels to cut the workpiece, usually at high rotational speeds. Grinding machine, mainly through the high-speed rotation of the grinding wheel on the workpiece for flat, cylindrical, internal hole, tool grinding, processing of the workpiece surface roughness is particularly high.

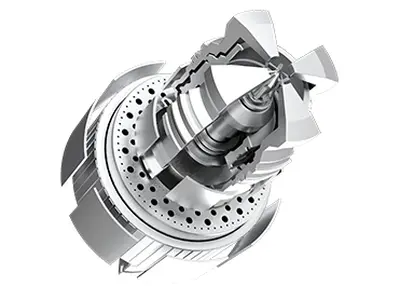

Reaming is a process used to create internal or external gears, cutting grooves and other complex contours. This is often used in the manufacture of gears, turbine blades and other parts.

Stamping is the process of cutting, shaping or punching sheet or strip metal through a punch on a press. This method is usually used to manufacture parts, housings and metal products.

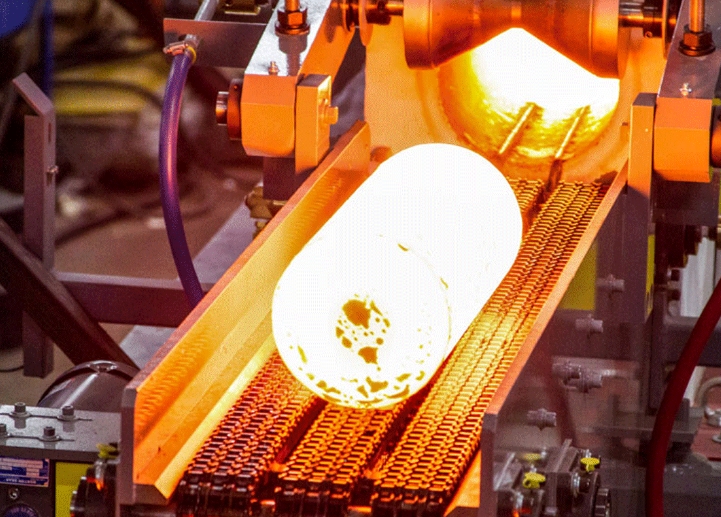

Forging is the process of changing the shape of metal by applying high temperature and pressure to it. This is often used to make high-strength and wear-resistant parts, such as engine parts and tools.

Injection molding is a process used to produce large quantities of plastic parts. It involves injecting heated plastic into a mold, allowing it to cool and harden into the desired shape.

EDM is a process that removes material by initiating an electric spark between the workpiece and an electrode. It is suitable for the manufacture of complex parts and for work with high hardness materials.

Heat treatment is a process that changes the properties of a material by controlling its temperature and cooling rate. It improves the hardness, strength and wear resistance of the material.

Welding is a process of joining two or more parts into a single unit. It is widely used in the fabrication of structures, pipes and various equipment.

Stretch Forming is a molding process used for plastics and sheet metal by stretching the material to a desired shape.

Powder metallurgy is a process used to make powdered metal parts. The powdered metal is mixed with a binder, then pressed and sintered to form the part.

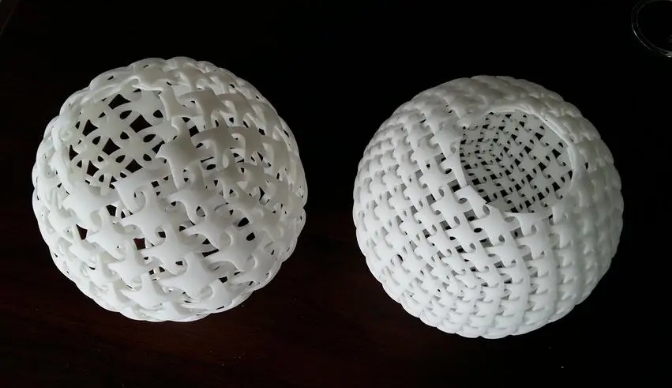

3D printing is a rapid manufacturing process that transforms digital models into solid parts by stacking materials layer by layer to create complex parts.

Injection molding, also known as injection molding, is a common plastics processing process used to manufacture a wide variety of plastic products covering a wide range of applications, from small parts to large components. An injection molding machine is the main piece of equipment that performs the injection molding process. It consists of a heated barrel, which is used to heat the plastic pellets into a molten state, and an injection head, which is used to inject the molten plastic into the mold.

Basic Parts of CNC Lathe and Their MaintenanceOctober 20, 2023CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc.view

Basic Parts of CNC Lathe and Their MaintenanceOctober 20, 2023CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc.view Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view

Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view Surface Finish 101: An Overview of Plastic Surface Finish ChartSeptember 5, 2023A process that involves the use of a machine to impose characteristic irregularities on the surface of its product. Constant use tends to cause the product to wear down over time. This is usually due ...view

Surface Finish 101: An Overview of Plastic Surface Finish ChartSeptember 5, 2023A process that involves the use of a machine to impose characteristic irregularities on the surface of its product. Constant use tends to cause the product to wear down over time. This is usually due ...view 4 Things You Need to Know About Anodised AluminiumAugust 11, 2023Anodised aluminium has become a buzzword in various industries, from automotive to electronics, and for good reason. This process transforms regular aluminium into a powerhouse material with enhanced ...view

4 Things You Need to Know About Anodised AluminiumAugust 11, 2023Anodised aluminium has become a buzzword in various industries, from automotive to electronics, and for good reason. This process transforms regular aluminium into a powerhouse material with enhanced ...view What is face milling?November 22, 2023Face milling is a metalworking process that is widely used in manufacturing and machining. It is a process in which the surface of a workpiece is cut by a milling cutter on a milling machine to obtain the desired shape, size and surface quality. Face milling can be used to process a variety of metallic and non-metallic materials, including steel, aluminum, copper, plastics and so on.view

What is face milling?November 22, 2023Face milling is a metalworking process that is widely used in manufacturing and machining. It is a process in which the surface of a workpiece is cut by a milling cutter on a milling machine to obtain the desired shape, size and surface quality. Face milling can be used to process a variety of metallic and non-metallic materials, including steel, aluminum, copper, plastics and so on.view The Difference Between Nickel Plated Rolls and Chrome Plated Rolls:A Comprehensive Comparison GuideAugust 3, 2023Nickel plated rollers and chrome plated rollers are two common electroplated roller products, widely used in printing, electronics, automobiles and other industries. Do you know the differences betwee...view

The Difference Between Nickel Plated Rolls and Chrome Plated Rolls:A Comprehensive Comparison GuideAugust 3, 2023Nickel plated rollers and chrome plated rollers are two common electroplated roller products, widely used in printing, electronics, automobiles and other industries. Do you know the differences betwee...view

EN

EN

ru

ru