Connecting rod parts play a vital role in the mechanical field and are commonly used in engines, vehicle drivelines, industrial machinery and other applications. In order to ensure their accuracy, reliability and performance, the manufacture of connecting rod parts needs to go through several machining processes. In this article, we will introduce the machining processes of connecting rod parts, including milling, turning, drilling, and grinding, to explain how to manufacture high-quality connecting rod parts.

Milling is one of the common processes used to manufacture connecting rod parts. The material is removed layer by layer by rotating the tool to obtain the desired shape and size. Milling machine can perform plane milling, vertical milling and CNC milling. This process is suitable for manufacturing flat surfaces, grooves and holes in connecting rods.

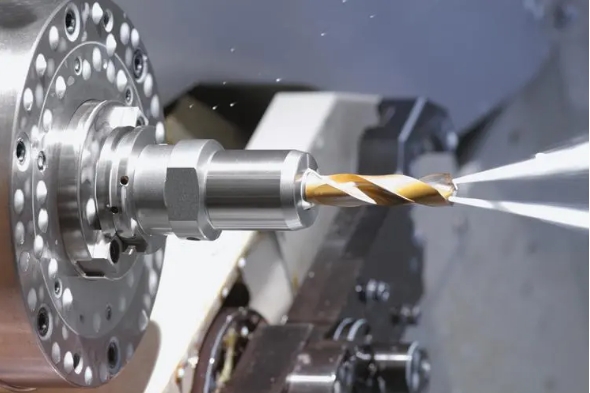

Turning is the process of changing the shape of the workpiece by rotating it and cutting it with a tool. This is the ideal method for producing connecting rod parts with round cross sections, such as crank bearing housings. CNC lathe technology allows precise control of the position and depth of the cutting tool, ensuring high accuracy.

Drilling is used to create holes in connecting rods. It can include conventional drilling, boring and boring to obtain holes of different shapes and accuracy. Drilling usually requires high axial accuracy to ensure accurate positioning and sizing of the holes.

Grinding is a high-precision process usually used to provide higher surface finish and dimensional accuracy. By placing a grinding wheel in contact with the workpiece, material can be removed to achieve very high surface quality. This is critical for critical connecting parts such as crank bearing housings.

In some cases, the manufacture of connecting rod parts may involve riveting or welding. These processes are used to join different parts together, such as cranks to connecting rods. Welding provides a strong connection but requires proper welding skills to ensure quality.

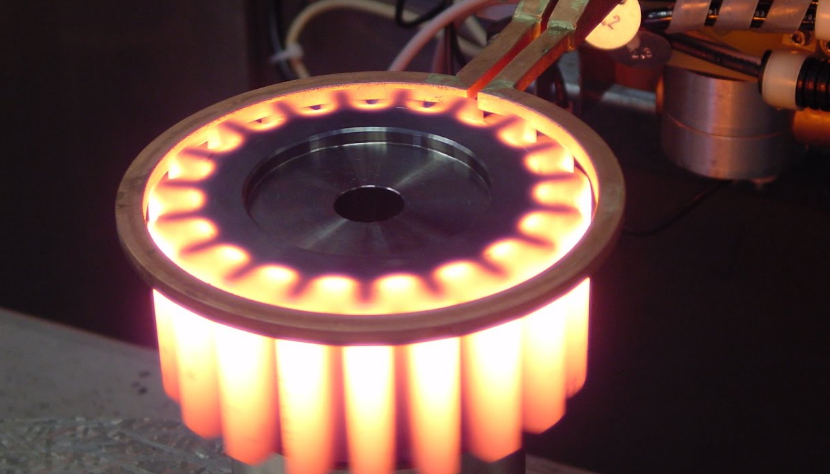

Heat treatment processes improve the hardness, strength and wear resistance of connecting rod parts. Typically, the part is heated to a certain temperature and then cooled rapidly to change its lattice structure. This is a critical process used to ensure the performance of the part under high load conditions.

Finally, the process of manufacturing connecting rod parts must include inspection and quality control steps. These steps are used to verify the size, shape, and surface quality of the part to ensure that it meets the design requirements.

The manufacture of connecting rod parts involves a variety of machining processes ranging from CNC milling and CNC turning to drilling, grinding and heat treating. Each process has its own unique application to ensure high accuracy, reliability and performance of the part. By properly selecting and controlling these processes, manufacturers can produce high-quality connecting rod parts for a variety of engineering applications.

All You Need to Know About the Significance and Methods of Limit Fit for CNC PartsJuly 23, 2024This article will explore the significance, methods, and processes of achieving limit fit for CNC parts in modern manufacturing, ensuring precision and quality.view

All You Need to Know About the Significance and Methods of Limit Fit for CNC PartsJuly 23, 2024This article will explore the significance, methods, and processes of achieving limit fit for CNC parts in modern manufacturing, ensuring precision and quality.view The Top 7 CAD/CAM Software for CNC ProjectsMarch 18, 2024CAD/CAM software for CNC projects is a specialized tool used to design and control the machining of parts. Here are the top 7 CAD/CAM software for your choice.view

The Top 7 CAD/CAM Software for CNC ProjectsMarch 18, 2024CAD/CAM software for CNC projects is a specialized tool used to design and control the machining of parts. Here are the top 7 CAD/CAM software for your choice.view Unlocking the World of Machined Bushes: Your Comprehensive GuideNovember 8, 2023Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.view

Unlocking the World of Machined Bushes: Your Comprehensive GuideNovember 8, 2023Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.view Understanding and Improving Modern CNC MillingOctober 11, 2023CNC MillingCNC milling has been around for more than 50 years, but the technology continues to evolve. Recent advances have made it possible to automate the entire process, from design to finished par...view

Understanding and Improving Modern CNC MillingOctober 11, 2023CNC MillingCNC milling has been around for more than 50 years, but the technology continues to evolve. Recent advances have made it possible to automate the entire process, from design to finished par...view Electrophoresis Metal Coating in Laboratory AutomationFebruary 29, 2024Navigating Precision in Laboratory AutomationIn the dynamic landscape of scientific research, the central axis of efficiency revolves around laboratory automation. At the nucleus of this efficiency li...view

Electrophoresis Metal Coating in Laboratory AutomationFebruary 29, 2024Navigating Precision in Laboratory AutomationIn the dynamic landscape of scientific research, the central axis of efficiency revolves around laboratory automation. At the nucleus of this efficiency li...view Anodized Aluminum: How Much Do You Know?April 4, 2023Anodized aluminum refers to a layer of dense aluminum oxide plated on the surface of aluminum and aluminum alloy in order to prevent further oxidation, with chemical properties that are the same as th...view

Anodized Aluminum: How Much Do You Know?April 4, 2023Anodized aluminum refers to a layer of dense aluminum oxide plated on the surface of aluminum and aluminum alloy in order to prevent further oxidation, with chemical properties that are the same as th...view

EN

EN

ru

ru