Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.

Numerous metals possess similar superpowers. While iron and its derivative carbon quickly rust without a protective layer of paint, electroplating or a similar coating, other metals such as aluminum and stainless steel form a thin protective layer called a "passivation layer" when combined with atmospheric oxygen. You can read more about this below.

We will spare you an explanation of the complex electromechanical mechanisms underlying the various corrosion processes here - these are mainly of interest to metallurgists and materials scientists. It is important to know, however, that high humidity and water (especially salt water) favor corrosion, and even the largest buildings and strongest bridges will eventually fall victim to it.

The good news is that there is a wide range of corrosion-resistant metals available. Using the most common metals, we can manufacture your components using CNC machining or 3D printing. Here is a brief overview with some application examples:

This element is an excellent choice for many applications. Its numerous alloys are strong, lightweight, electrically conductive and non-magnetic. Its uses are extremely diverse, ranging from cookware and garden furniture to machine parts, electronics housings and scientific instruments.

We carry five grades of aluminum for CNC machining and one grade for 3D printed parts. 6082-T651, a general-purpose alloy comparable to 6061, is good for milling, turning, bending, forming, welding and laser machining. 7075-T651 and 7075-T7351 are both used in the aerospace industry, the latter being tougher and more durable. 5083-H111 offers increased corrosion resistance due to its higher magnesium content. 2024-T351 is also used in aerospace applications due to its high fatigue resistance, especially for components under stress.

For 3D-printed parts, we offer AlSi10Mg, a tough aluminum alloy that has long been used for castings. As for the thin protective layer mentioned earlier, aluminum forms a layer of aluminum oxide, an extremely hard chemical compound often found on grinding wheels. If you want an even harder coating, anodizing is also an option.

This bead blasted aluminum flange has been treated with small glass beads. The result is an attractive, smooth look and feel. To avoid sharp edges, the corners of this CNC machined part have also been smoothed. Like all aluminum parts, this one is extremely corrosion resistant.

Let it be said up front that this lightweight metal comes at a price. If it's still an option for you, please read on. Scientifically speaking, titanium is just as strong as steel, but weighs half as much. Compared to aluminum, it is twice as strong, but weighs one and a half times as much. In addition, titanium is one of the most corrosion-resistant metals because it forms a titanium oxide layer when combined with oxygen.

The titanium alloy Ti6Al4V is rightly called a "workhorse" due to its extremely wide range of applications. Applications include medical implants, aircraft engines, power generation equipment, and sports equipment, as it is ideally suited for CNC machining and 3D printing.

Titanium retains its toughness and corrosion resistance even when polished, and its bright surface is impressive. In addition, titanium is also resistant to numerous acids, chemicals and salt water.

This steel alloy forms a chromium oxide layer for protection. Chromium is a component of all stainless steel grades. 304 or A2 is a good general-purpose alloy used for such things as cutlery and fresh water applications. 316 or A4 stainless steel is a harder, heat-, wear- and corrosion-resistant grade, thanks to its 2 percent molybdenum content. Because it withstands salt water (at room temperature), the alloy is also suitable for marine applications. The grades listed also meet the requirements for "low carbon" alloys, denoted by an "L," such as 304L and 316L. They are slightly softer and easier to weld. Last but not least, we have 17-4 PH ("PH" stands for Precipitation Hardening), another favorite in the aerospace industry. Unlike 300-series stainless steel grades, 17-4 can be precipitation hardened by heat treatment. The grade is therefore often used in gas turbines, petrochemical applications and aircraft parts.

This alloy has many of the mechanical advantages of stainless steel, but is slightly stronger and more wear resistant. The alloy's biocompatibility makes it suitable for applications such as jewelry, dental fillings, and artificial joints, but it is also used in numerous industrial applications such as furnace linings and engine parts. Note: While the stainless steel grades listed above are commonly used at Richconn for CNC machining, turned parts and DMLS (direct metal laser sintering), we currently only offer the cobalt-chromium superalloy Co28Cr6Mo in DMLS 3D printing.

We also offer this grade only for DMLS. The superalloy (like all superalloys) is difficult to machine. However, we can use it to produce excellent 3D-printed parts up to 400 mm × 800 mm × 500 mm in our plant. Like the stainless steel grade 17-4, Inconel 718 can also be hardened by means of a precipitation process. However, it contains a much higher nickel content (about ten times as much) as well as about 5 percent of the refractory metal niobium and an almost similar amount of molybdenum. This explains the high strength and heat resistance, making the alloy especially suitable for applications up to 700 °C and extreme mechanical loads. Of course, it also resists any kind of corrosion.

This alloy of copper and zinc behaves exactly opposite to Inconel, titanium and cobalt-chromium in terms of its machinability. It is nevertheless equally valuable, especially when a corrosion-resistant metal that is easy to machine is desired, such as for plumbing fixtures and adapters, bearings, cold plates, screw fasteners and other parts that require high electrical and thermal conductivity. Richconn offers two grades of brass. Called C360 free-cutting brass (Cz121 or CuZn36Pb3), its name is derived from the low lead content that facilitates machining and makes this yellow metal a popular material for high-volume screw manufacturing. Similarly, C464 (Cz112 or CuZn36Sn1) is known as marine brass because it is preferred for marine parts due to its excellent corrosion resistance. For turned and milled parts, brass is an attractive alternative with numerous excellent properties, and is popular not least because of its attractive appearance.

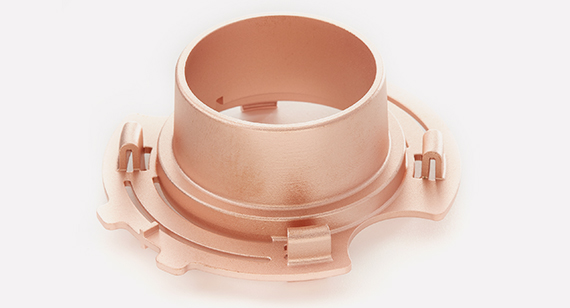

A close look reveals the deburred edge on this brass flange. For parts with broken edges, radii or chamfers are incorporated to avoid sharp edges and provide a smooth contour.

Rounding out our top corrosion-resistant metals is the C101 copper alloy. It is one of the earthly metals with the highest electrical - and thermal - conductivity. In terms of application versatility, copper is comparable to brass to some extent. However, it can be shaped better overall, but is not as easy to machine and is a little more expensive. It is ideal for high-performance heat exchangers and electronic and electrical applications (e.g., EMI shielding). Copper is also increasingly used in hospital supplies thanks to its antimicrobial properties.

Copper provides an attractive product appearance and is characterized by the fact that it corrodes aesthetically over time. The accumulation of carbon and oxygen molecules forms an attractive and protective bluish-green patina of copper carbonate.

Have we convinced you? As you can see, we offer a wide range of corrosion-resistant metals for your next project. Take advantage of our short delivery times and get the precision parts you need in no time, whether by CNC turning, CNC milling or metal 3D printing.

Finally, we would like to mention that you can also choose from a wide range of engineering polymers with us. Likewise, the weather resistance of metals prone to rusting, such as low-carbon steels (wrought iron) and EN8 alloys, can be significantly improved by appropriate surface treatment. Please note that such treatment may also be necessary for some of the metals explained above. For aluminum, for example, anodizing is usually recommended. Stainless steel materials should also be passivated for improved corrosion resistance.

We also recommend that you take a look at the extensive list of material data sheets on our website. These contain further details on the individual materials. Here you will also find more details on the corrosion resistant metals mentioned above. If you have any questions, please feel free to contact us. Our application engineers are available by phone at +86-0755-28025755 or at sales@richconn.com.cn.

Alloy Steel vs Carbon Steel: What are the Differences and Advantages?November 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance.view

Alloy Steel vs Carbon Steel: What are the Differences and Advantages?November 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance.view Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view

Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view CNC Plastics Selection Guide | Machining MaterialsJune 18, 2024Delve into the realm of engineering plastics to discover a wide range of materials, their unique characteristics, and diverse processing techniques.view

CNC Plastics Selection Guide | Machining MaterialsJune 18, 2024Delve into the realm of engineering plastics to discover a wide range of materials, their unique characteristics, and diverse processing techniques.view Selective Laser Sintering: Everything You Need to KnowAugust 4, 2023Selective laser sintering (SLS) is a groundbreaking additive manufacturing technique that has revolutionized various industries. Using a laser as both the power and heat source, SLS binds powdered mat...view

Selective Laser Sintering: Everything You Need to KnowAugust 4, 2023Selective laser sintering (SLS) is a groundbreaking additive manufacturing technique that has revolutionized various industries. Using a laser as both the power and heat source, SLS binds powdered mat...view Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view

Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view Exploring the World of High-Speed MachiningNovember 22, 2023In the ever-evolving landscape of manufacturing, the pursuit of efficiency and precision has led us to the realm of High-Speed Machining (HSM).view

Exploring the World of High-Speed MachiningNovember 22, 2023In the ever-evolving landscape of manufacturing, the pursuit of efficiency and precision has led us to the realm of High-Speed Machining (HSM).view

EN

EN

ru

ru