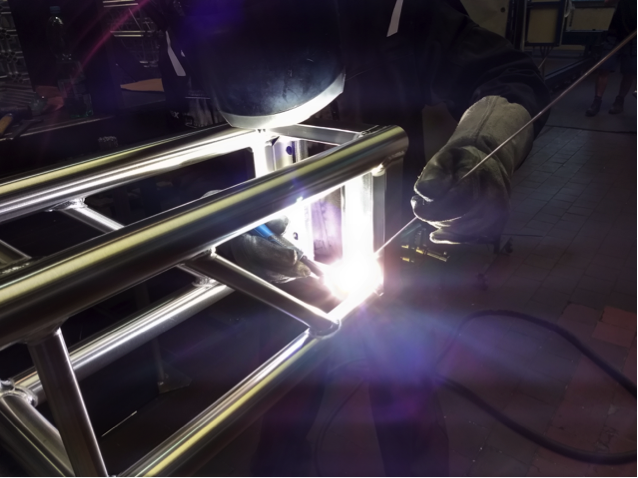

Are you ready to master the art of welding? If you're diving into the world of metalwork, understanding the differences between MIG welding and TIG welding is your first step. Whether you're a beginner seeking guidance or a seasoned welder looking to refine your skills, this comprehensive guide will equip you with the knowledge needed to make informed decisions.

When it comes to joining metals, MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are two popular methods.

MIG welding employs a wire electrode and a shielding gas to create a strong bond between metals. It's known for its speed and versatility, making it ideal for beginners and professionals alike.

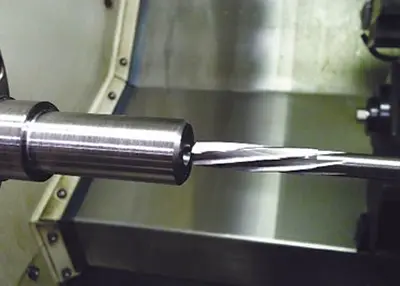

On the other hand, TIG welding uses a non-consumable tungsten electrode and a separate filler material. It's cherished for its precision and fine control, making it the choice for intricate work.

.png)

Understanding which welding method suits your project starts with knowing the materials and applications they excel in.

MIG welding is your go-to for projects involving steel, aluminum, and stainless steel. It's widely used in automotive, construction, and general fabrication.

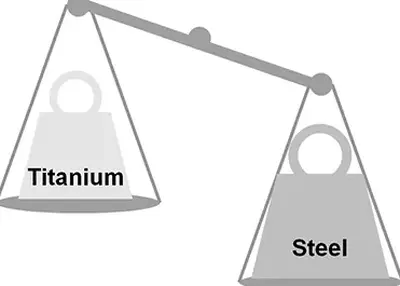

TIG welding shines when working with exotic metals like titanium and magnesium. Aerospace, artwork, and delicate metal sculptures often require the finesse of TIG welding.

| Welding Method | Suitable Materials | Typical Applications |

|---|---|---|

| MIG Welding | Steel, Aluminum, Stainless Steel | Automotive, Construction |

| TIG Welding | Titanium, Magnesium, Stainless Steel | Aerospace, Artwork, Sculptures |

Let's dive deeper into the comparison between these two welding methods to help you make the right choice.

MIG welding offers good arc stability, but TIG welding provides exceptional control over the arc. This makes TIG welding the winner for precision work.

MIG welding is faster due to its continuous wire feeding, making it efficient for large projects. TIG welding, while slower, excels in producing high-quality, clean welds.

If aesthetics matter, TIG welding produces welds with a cleaner, more refined appearance. MIG welding, while strong, may require more post-welding cleanup.

Consider the position of your workpiece. MIG welding is versatile and works well in various positions, while TIG welding demands more skill, especially in overhead or vertical welding.

MIG welding can be automated, making it suitable for mass production. TIG welding is more hands-on and requires precise manual control.

For diverse applications, MIG welding is adaptable and offers various wire types. TIG welding can handle a wide range of metals, but it requires changing the filler material for each.

Now, let's address your skill level and training needs.

If you're just starting, MIG welding's simplicity and forgiving nature make it an excellent choice. Focus on mastering the basics before diving into TIG welding.

Invest in your skills with welding courses, online tutorials, and hands-on training. Seek guidance from experienced welders to accelerate your learning curve.

Practice regularly, maintain proper safety measures, and keep learning. Welding is an art that improves with time and dedication.

Let's explore how to apply MIG and TIG welding methods to your projects.

For structural or heavy-duty work, MIG welding is efficient. Ensure proper prep, including clean surfaces and appropriate settings.

Precision welding projects demand TIG welding. Plan meticulously, maintain a steady hand, and take your time to achieve the desired results.

Before you start welding, gather the necessary equipment, ensure proper safety gear, and make sure your workspace is well-ventilated.

Master essential welding techniques, such as bead placement, travel speed, and electrode manipulation. These skills are vital for producing strong and visually appealing welds.

Safety should always be a top priority in welding.

Protect yourself with the right gear, including welding helmets, gloves, and clothing. Be aware of potential hazards, such as sparks and fumes.

Regularly inspect and maintain your welding equipment to ensure safe and reliable operation. Proper care prolongs the life of your gear.

Consider your project requirements, materials, and skill level when choosing between MIG and TIG welding.

Your choice of welding method can significantly impact your project's outcome. Take your time to evaluate your needs and practice your chosen method to become proficient.

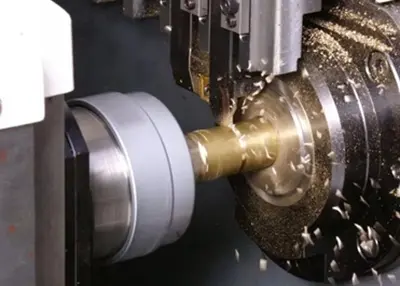

Before we move on to the next section, it's worth mentioning that Richconn is a professional CNC machining services company based in China. They offer a wide range of precision machining services, including CNC milling, turning, and more. If your welding projects require precision-machined parts, Richconn could be a valuable resource for you.

As you progress in your welding journey, it's important to explore advanced techniques and considerations for both MIG and TIG welding.

Pulse MIG Welding: Achieving better control and reduced heat input.

Spray Transfer Mode: When to use it for high deposition rates.

Selecting the Right Shielding Gas: Optimizing gas choices for specific materials.

TIG Welding on Thin Materials: Techniques for preventing warping and burn-through.

Using Specialty Tungsten Electrodes: Exploring the benefits of different electrode types.

Controlling Heat Input: Strategies for avoiding distortion in your workpiece.

Welding Aluminum Alloys: Addressing the challenges and nuances.

Welding Dissimilar Metals: Techniques for achieving strong joints between different materials.

Welding Outdoors: Managing wind and environmental factors.

Welding in Confined Spaces: Safety precautions and equipment considerations.

Both MIG and TIG welding find their applications in specialized fields. Let's delve into these unique applications.

Structural Welding in Car Frames: Ensuring safety and stability.

Custom Exhaust Systems: Crafting performance-enhancing components.

Precision Welding of Aircraft Components: Meeting stringent quality standards.

Welding Titanium for Aircraft: Addressing the challenges of this demanding material.

Sculptural Welding Techniques: Creating intricate metal artworks.

Combining Welding and Artistry: Exploring the possibilities of metal sculpture.

The welding industry is evolving rapidly with automation and new technologies. Stay updated on the latest trends.

Robotics in Welding: The role of robots in achieving precision and efficiency.

Welding Software and Control Systems: Streamlining operations and quality control.

Sustainable Welding Practices: Reducing environmental impact with efficient processes.

Clean Welding Technologies: Innovations in emissions reduction and waste management.

Additive Manufacturing and 3D Printing: How these technologies are transforming welding.

Smart Welding Helmets and Augmented Reality: Enhancing safety and precision.

For those pursuing welding as a profession, understanding international standards and certifications is essential.

AWS Welding Codes: The American Welding Society's standards for quality.

ISO Welding Standards: International standards for welding quality and safety.

Becoming a Certified Welder: Steps to obtain recognized welding certifications.

Advantages of Certification: How certification can boost your career in welding.

Lifelong Learning: Embracing continuous improvement in your welding skills.

Sharing Knowledge: Becoming a mentor and contributing to the welding community.

Richconn's CNC Machining Services: How precision-machined parts complement welding projects.

Partnering with Richconn: Leveraging their expertise for your welding needs.

What Is Reaming & Reamer And Their DifferencesSeptember 26, 2023Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction.view

What Is Reaming & Reamer And Their DifferencesSeptember 26, 2023Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction.view Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view

Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view

What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view Aerospace CNC Machining: A Comprehensive GuideNovember 6, 2023Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.view

Aerospace CNC Machining: A Comprehensive GuideNovember 6, 2023Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.view Common Cheap CNC Material - An Overview of PlasticsJune 17, 2024Cheap CNC Material——ABSABS is one of the most common cheap CNC material, with good mechanical properties, excellent impact strength, high heat resistance, and good machinability.ABS has a low densit...view

Common Cheap CNC Material - An Overview of PlasticsJune 17, 2024Cheap CNC Material——ABSABS is one of the most common cheap CNC material, with good mechanical properties, excellent impact strength, high heat resistance, and good machinability.ABS has a low densit...view

EN

EN

ru

ru