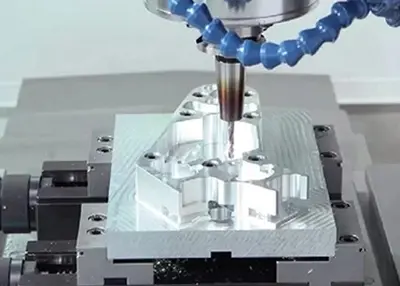

Many of our customers order parts that come ready-made from plastic injection molding or CNC machining. Many others, however, want or need "secondary machining" of the parts so produced. These processes are referred to as "secondary services." They can be an integral part of a customer's project requirements.

Secondary services may be required to meet the process control, functional, or cosmetic (usually branding or labeling) requirements of a given project. These requirements will determine if additional services are needed.

The customer may have very specific requirements for oversight of the design and development process (monitoring and recording part dimensions) such as additional sampling and detailed measurements.

Sometimes the parts are components of an assembly that must first be assembled and then incorporated into the final product. Automated sub-assembly and final assembly may not be economical for the customer for on demand manufacturing runs. By supplying fully assembled sub-assemblies, time and cost advantages can be realized through simpler final production.

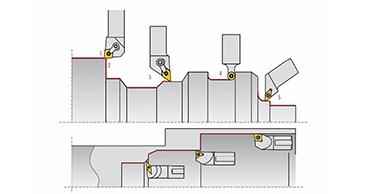

There is a wide range of secondary and support services that can be provided for injection molded and CNC parts. Common ones include:

# Detailed inspection and measurement (to support PPAP and other industry standard quality control processes).

# Anodizing of aluminum CNC parts

# Structuring of customer mold

# Ultrasonic welding. Ultrasonic welding applies high frequency acoustic vibrations to join two components by friction. The process is particularly useful for joining dissimilar materials. It can also be used to add metal inserts to injection molded parts after molding.

# Hot caulking. In hot caulking, metal or threaded inserts are inserted into plastic parts after molding and positioned using heat and pressure.

# Pad printing. Pad printing involves filling a steel plate with an etched pattern with ink, which is then transferred to an injection-molded plastic part. This allows a part to be quickly and economically imprinted with a logo, part number, graphic instructions or other text or images.

# IML (In-Mold Labeling). In the IML process, a printed label is inserted into a mold before the liquid plastic is injected. When the mold is filled with the plastic, the label is firmly bonded to the part.

# Laser Etching and Part Marking. Laser etching uses a laser to etch a contrasting image or text into a plastic part.

Richconn's secondary services are now being gradually introduced, starting with:

* Inspection and measurement

* Mold structuring

* Anodizing serivice

* Simple assembly

Whether you need a part straight from the mold or CNC milling, or your project would benefit from secondary services, we can help you get the exact end product you want. Talk to us about your requirements - please contact sales@richconn.com.cn. We look forward to hearing about your project.

Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view

Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view Five Axis CNC Machining Features and AdvantagesNovember 4, 2022Five-axis machining machines to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way...view

Five Axis CNC Machining Features and AdvantagesNovember 4, 2022Five-axis machining machines to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way...view What Are the General Types of Measurement Methods for Machining Accuracy of Machine Parts?October 27, 2023Machining accuracy is the actual size, shape, position of the surface of the machined part three kinds of geometric parameters and drawings required by the ideal degree of compliance with the geometric parameters.view

What Are the General Types of Measurement Methods for Machining Accuracy of Machine Parts?October 27, 2023Machining accuracy is the actual size, shape, position of the surface of the machined part three kinds of geometric parameters and drawings required by the ideal degree of compliance with the geometric parameters.view American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view

American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view What Is Anodizing: Exploring the Anodizing Process and TypesAugust 31, 2023Anodizing goes beyond surface enhancement; it represents an extraordinary electrochemical transformation that endows a diverse range of metals with exceptional characteristics. If you've ever wond...view

What Is Anodizing: Exploring the Anodizing Process and TypesAugust 31, 2023Anodizing goes beyond surface enhancement; it represents an extraordinary electrochemical transformation that endows a diverse range of metals with exceptional characteristics. If you've ever wond...view Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view

Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view

EN

EN

ru

ru