The world of manufacturing has undergone a remarkable transformation with the advent of online 3D printing. This innovative technology has revolutionized how we bring ideas to life, offering a convenient and cost-effective way to turn digital designs into physical objects. Online 3D printing services have emerged as the go-to solution for individuals and businesses seeking high-quality custom parts.

3D print online, also known as 3D printing service, allows you to harness the power of this cutting-edge technology without the investment in specialized equipment. The process begins with a digital 3D model of the object you want to create. This model is uploaded to a 3D printing online service platform, where you can select from a variety of materials and finishes to suit your project's requirements. The service provider then uses their 3D printers to bring your design to life, layer by layer, resulting in a tangible, physical representation of your concept.

The history of 3D printing dates back to the 1980s, when the first patent for a stereolithography apparatus was filed by Charles Hull in 1986. Since then, 3D printing has evolved significantly and expanded its applications to various fields, such as aerospace, automotive, medical, and consumer products.

As the demand for 3D printing technology grew, especially from businesses that initially hadn't allocated a budget for 3D printing equipment, the concept of online 3D printing gained prominence. This approach provided a cost-effective and accessible solution for companies and individuals seeking to harness the benefits of 3D printing without the burden of owning and maintaining specialized hardware.

The range of available 3D printing methods has expanded over the years, leading to a selection of techniques that cater to various needs and industries.

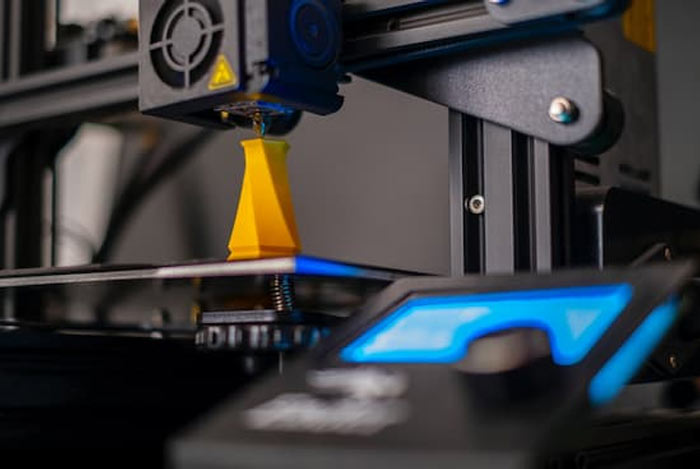

Fused Deposition Modeling (FDM): FDM, also known as Fused Filament Fabrication (FFF). This method involves extruding a thermoplastic filament through a heated nozzle, which deposits layers of material to build the final object. It's excellent for rapid prototyping and is often the go-to choice for those starting their 3D print Online journey due to its user-friendly nature.

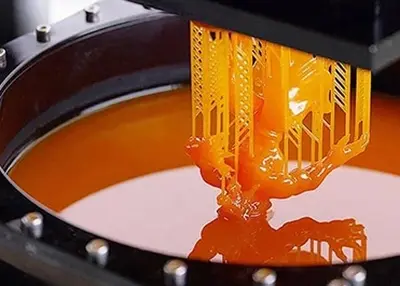

Stereolithography (SLA): SLA employs a different approach, utilizing a UV laser to solidify liquid photopolymer resin layer by layer. This technique is renowned for producing exceptionally detailed and high-resolution models with smooth surface finishes.

Selective Laser Sintering (SLS): SLS is a versatile 3D printing method that stands out for its ability to work with a range of materials, including plastics, metals, and ceramics. Selective laser sinter is popular for its durability, functional end-use parts, and the ability to create complex geometries.

There are more exciting advancements like Direct Metal Laser Sintering (DMLS) and the innovative Multi Jet Fusion (MJF) that we haven't delved into yet. These emerging methods offer unique features and are shaping the future of 3D printing.

The wide range of materials available for online 3D printing is a game-changer, providing designers, engineers, and manufacturers with a versatile toolkit to bring their concepts to life.

Traditional Plastics: Materials like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) are staples in 3D printing. They are known for their affordability, ease of use, and wide availability. These plastics are excellent for rapid prototyping, functional parts, and even artistic creations.

Advanced Polymers: Beyond the basics, online 3D printing offers access to a variety of advanced polymers. Nylon, for instance, is known for its durability, flexibility, and resistance to wear and tear. It's a great choice for producing functional components that need to withstand stress.

Carbon Fiber-Reinforced Composites: These materials combine the lightweight properties of polymers with the strength of carbon fibers. They are ideal for producing parts that need to be both lightweight and strong, making them popular in industries like automotive and aerospace.

Metals: Online 3D printing with metals has revolutionized manufacturing in industries that demand high-strength, heat-resistant, and corrosion-resistant components. Aluminum, stainless steel, and titanium are frequently used metals, providing exceptional mechanical properties for applications ranging from engineering prototypes to medical implants.

There are also advanced materials such as Ceramics and Flexible Materials that have not yet been mentioned. The beauty of these diverse material selections is that it aligns with the specific needs of various industries.

Online 3D printing offers a plethora of benefits, including customization and rapid prototyping. However, some challenges must also be taken into account.

Seamless Online Interaction

The online nature of these services allows users to conveniently upload their 3D models, choose materials and finishes, and receive real-time quotes. This interactive process provides users with immediate feedback, ensuring that their designs are compatible with the chosen 3D printing technology and materials. Online platforms often offer design analysis tools, enabling users to detect potential issues in their models before printing.

Customization

3D printing Online enables unparalleled customization. Whether you need a unique prototype, a personalized gift, or a specialized part for a specific application, you can design and produce it exactly as you envision.

Rapid Prototyping

Traditional manufacturing methods often involve expensive molds and lengthy lead times for prototypes. With online 3D printing, you can quickly iterate and test designs, significantly reducing the time and cost of prototyping.

Speed and Cost-Effectiveness

Online 3D printing is remarkably efficient in terms of both time and cost. Traditional manufacturing methods often involve complex setups and long production runs. In contrast, 3D printing eliminates the need for tooling, reduces waste, and allows for on-demand production.

Intellectual Property Rights

As online 3D printing becomes more accessible, concerns about intellectual property (IP) rights arise. There's a need to ensure that designs are not illegally replicated or used without permission.

Environmental Sustainability

While 3D printing reduces waste compared to traditional manufacturing, it's essential to consider the overall environmental impact. Some 3D printing materials may have a significant carbon footprint, and the disposal of unused or discarded printed parts must be managed responsibly.

Quality and Consistency

Maintaining consistent quality across 3D printed parts, especially in large-scale production, can be challenging. Factors such as layer adhesion, surface finish, and dimensional accuracy require careful attention.

As you evaluate various options, consider the following aspects that make Richconn-CNC stand out as a top-notch provider in the industry:

Technology and Capabilities

One of the first things to assess is the range of 3D printing technologies and materials available on the platform. Richconn-CNC offers a comprehensive selection of 3D printing methods, including FDM, SLA, SLS, DMLS, and MJF, allowing you to choose the technology that best suits your project's requirements.

Material Variety

The ability to choose from a diverse array of materials is essential to match your specific needs. Richconn-CNC features engineering-grade materials from plastics like ABS and polycarbonate to metals such as aluminum and stainless steel, ensuring that you can find the right material for your application.

Quality Assurance

Ensuring consistent high quality is paramount. Richconn-CNC employs a strict quality management system, conducting full inspections to eliminate defects or errors.

Expertise and Experience

Richconn-CNC boasts more than a decade of experience in CNC machining and 3D printing. Their seasoned team has served diverse industries, including automotive, electronics, medical, and manufacturing.

Fast Lead Time

Time is often of the essence in product development and manufacturing. Richconn-CNC's digital platform streamlines the ordering process, coupled with experienced staff, ensuring a fast production turnaround for your prototypes or parts.

Customer Support and Feedback

A reliable 3D print online service should offer prompt customer support and a straightforward feedback mechanism. Richconn-CNC provides instant quotes, as well as the option to request samples, allowing you to test the quality and accuracy of their 3D printing service online before committing to a larger production.

From the array of materials to the advantages of rapid customization, online 3D printing embodies a world of possibilities. As we navigate the advantages and challenges, it's clear that a 3D printing supplier like Richconn-CNC stands ready with cutting-edge technology, an extensive material palette, and a proven track record of excellence. As Richconn embraces the revolution of online 3D printing, the future of manufacturing looks brighter, more accessible, and more exciting than ever before.

3D Printed Car Parts: All About 3D Printing in the Automotive IndustryMarch 1, 20243D printing for car parts caters to the personalization needs of many companies without compromising quality. Find out everything you need about 3D printed car parts here.view

3D Printed Car Parts: All About 3D Printing in the Automotive IndustryMarch 1, 20243D printing for car parts caters to the personalization needs of many companies without compromising quality. Find out everything you need about 3D printed car parts here.view What Are the Characteristics of the Surface Treatment Process for Titanium Alloy Materials?October 30, 2023Titanium alloys are a variety of alloy metals made of titanium and other metals, which are relatively scarce and expensive; titanium alloys are characterized by high strength, light weight, corrosion resistance and high temperature resistance, and can be used in a variety of fine chemicals, which are mainly used in the automotive industry, aerospace, nuclear industry, chemical and petrochemical industries, dentistry and medical restoration and other fields.view

What Are the Characteristics of the Surface Treatment Process for Titanium Alloy Materials?October 30, 2023Titanium alloys are a variety of alloy metals made of titanium and other metals, which are relatively scarce and expensive; titanium alloys are characterized by high strength, light weight, corrosion resistance and high temperature resistance, and can be used in a variety of fine chemicals, which are mainly used in the automotive industry, aerospace, nuclear industry, chemical and petrochemical industries, dentistry and medical restoration and other fields.view Semiconductor Chip Carrier Manufacturing: Introduction from Materials to Finished ProductsAugust 14, 2023With the development of science and technology, semiconductor chips are being widely used in various fields. High quality chip carriers are crucial to ensure the performance of chips during semiconduc...view

Semiconductor Chip Carrier Manufacturing: Introduction from Materials to Finished ProductsAugust 14, 2023With the development of science and technology, semiconductor chips are being widely used in various fields. High quality chip carriers are crucial to ensure the performance of chips during semiconduc...view CNC Water Jet Cutter: Precision in Cutting TechnologySeptember 28, 2023Have you ever dreamed of achieving flawless precision in cutting materials, from metal to delicate fabrics, with utmost efficiency and accuracy? Your dream can become a reality with the marvel of technology known as the CNC Water Jet Cutter.view

CNC Water Jet Cutter: Precision in Cutting TechnologySeptember 28, 2023Have you ever dreamed of achieving flawless precision in cutting materials, from metal to delicate fabrics, with utmost efficiency and accuracy? Your dream can become a reality with the marvel of technology known as the CNC Water Jet Cutter.view![Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]](/uploads/image/20231123/14/chamfer-101-understanding-chamfers-and-chamfered-edge-quick-guide_400x400.webp) Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view

Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view Switching From Metal to PlasticOctober 18, 2023The manufacturing sector is constantly evolving as new trends and processes emerge. Among the most interesting trends is the relatively new idea of designers to replace metal parts with plastic injection molding.view

Switching From Metal to PlasticOctober 18, 2023The manufacturing sector is constantly evolving as new trends and processes emerge. Among the most interesting trends is the relatively new idea of designers to replace metal parts with plastic injection molding.view

EN

EN

ru

ru