Nowadays, the prowess of precision machining lies in the unfaltering delivery of unparalleled quality, precision, and intricacy, which reverberates across a spectrum of industries. With advanced technology and craftsmanship, precision machining employs computer-controlled machine tools to meticulously shape components with meticulous tolerances and intricate contours. Precision machining services bring forth the likes of Richconn and a plethora of companies that cater to the intricate needs of sectors like aerospace, medical, automotive, and electronics, facilitating the creation of bespoke parts that form the bedrock of modern existence.

Precision machining represents a fusion of state-of-the-art technology and meticulous craftsmanship, yielding components that embody exceptional accuracy and intricate detail.

Precision machining is a meticulous and intricate process that transforms raw materials into finely crafted components with unparalleled accuracy and detail. Through a combination of advanced machinery, skilled craftsmanship, and cutting-edge technology, precision machining ensures that even the most intricate designs are brought to life with impeccable precision.

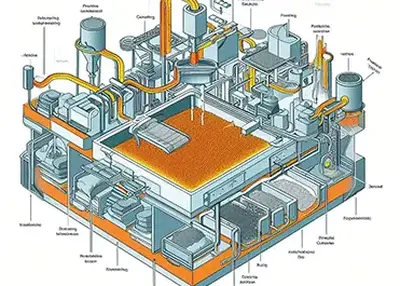

Precision machining involves the use of computer-controlled machine tools, commonly referred to as CNC machines, to shape and sculpt materials into the desired forms. These machines follow a precise program that dictates every movement of the cutting tool, down to fractions of a millimeter. The result is that parts fit seamlessly together, even in the most complex assemblies.

Precision machining begins with meticulous planning and design. Engineers work closely with clients to understand their needs and translate them into precise specifications. These specifications encompass not only the dimensions of the part but also the tolerances it must adhere to, ensuring a perfect fit and optimal functionality. With the design in place, the CNC program is developed, providing the machine with a step-by-step guide to crafting the part.

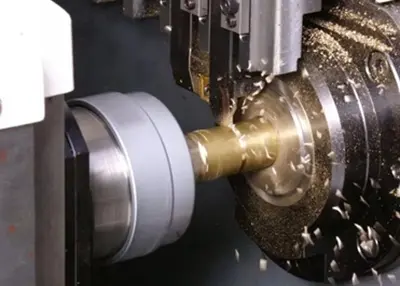

The CNC machine then takes center stage, executing its program with astonishing accuracy. Whether it's CNC milling, CNC turning, routing, or EDM, each method leverages specialized tools to remove material in a controlled manner, sculpting the workpiece into the desired shape. This level of precision is unrivaled by traditional machining methods, where human error and inconsistencies can compromise the final product.

At the same time, precision machining services companies such as Richconn usually invest in state-of-the-art machinery, employ skilled machinists, and maintain stringent quality control processes. Every step of the machining process is monitored, measured, and refined to ensure that the end product meets or exceeds the client's expectations.

From the grandeur of aerospace engineering to the intricacies of electronic gadgets, the profound impact of precision machining reverberates throughout a diverse array of industries.

Every gram in aerospace engineering matters, its performance is non-negotiable, where precision machining takes center stage. Think of turbine blades that endure extreme temperatures and forces while propelling aircraft at astonishing speeds. These blades are meticulously crafted through precision machining, ensuring reliable and efficient propulsion.

Precision machining lends its expertise to crafting flight controls as well as engine components. The meticulous design and manufacturing of these components amplify not only performance but also safety, crucial in this high-stakes domain.

Instruments, ranging from delicate diagnostic tools to life-saving devices like pacemakers, are a testament to precision machining's contribution to healthcare. The role of precision machining extends further into the creation of implants, where every millimeter matters. These components require not only precise dimensions but also biocompatibility to ensure seamless integration into the human body.

Precision-machined gears in the automotive sector form the backbone of transmissions, enabling seamless power delivery and smooth gear changes. These components undergo rigorous machining processes to ensure they can withstand the demands of daily driving.

Brake discs, pistons and other vital components endure intense heat and stress. Precision machining ensures they meet exacting standards, promoting safe braking and vehicle control.

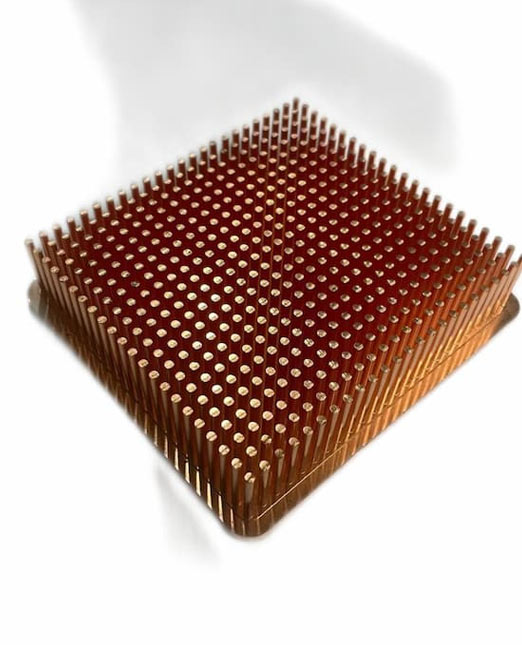

The electronics industry, with its ever-shrinking components and complex designs. The intricacy of their design, with minuscule transistors etched onto silicon wafers, demands precision that only machining can provide. Precision machining ensures that these are manufactured with micron-level accuracy, enabling the seamless functionality of our gadgets.

The precision machining universe encompasses a multitude of methods and equipment, each catering to specific requirements:

Utilizing rotating cutting tools, CNC milling involves removing material from a workpiece to create precise shapes and features. It excels in producing complex geometries and is widely used in industries like automotive and aerospace.

Employing cutting tools to remove material from a rotating workpiece, CNC turning is a staple for creating cylindrical components with high precision, commonly seen in applications like medical instruments and automotive parts.

This method employs computer-controlled routers to carve intricate designs and shapes from various materials, making it indispensable in the production of furniture, signs, and electronic enclosures.

EDM involves the use of electrical discharges to erode material from a workpiece. It is crucial in crafting intricate shapes that are challenging to achieve through traditional methods, such as in aerospace turbine blades.

Precision machining stands as a beacon of innovation, revolutionizing the manufacturing landscape across industries.

At the heart of precision machining lies its unparalleled ability to achieve microscopically precise tolerances. This capability ensures that each component fits seamlessly into intricate assemblies, enabling optimal functionality.

The versatility of precision machining is a testament to its capability to handle a diverse spectrum of materials with finesse. From conventional metals to exotic alloys and even cutting-edge composites, precision machining navigates this material diversity effortlessly.

By meticulously removing only the necessary material, waste is minimized, thus significantly reducing the environmental footprint of the manufacturing process. Meanwhile, the automated precision of CNC (computer numerical control) machines further expedites production, resulting in not only cost-effective operations but also practices that align with environmentally conscious principles.

Whether manufacturing a single intricate part or producing thousands of components, precision machining delivers identical quality and accuracy across the board. This level of consistency is a testament to the meticulous control exercised throughout the process, ensuring that each part upholds the highest standards.

Precision machining service aims to create components that redefine accuracy and complexity.

At Richconn, we specialize in custom CNC machining, a process that harnesses the power of computer-controlled machines to sculpt intricate parts from a range of materials. With advanced equipment, an expert team, and a flexible supply chain, Richconn as a professional precision machining company is poised to translate your visions into reality.

The collaboration commences with a deep dive into your requirements. Through close consultation, Richconn tailors the design that aligns with your vision and functional needs, ensuring that each component serves its purpose seamlessly.

Prototyping acts as the bridge between concept and creation. Richconn's prototyping phase allows for refinement, ensuring that the final product adheres to the highest standards of precision and functionality.

Leveraging state-of-the-art CNC machines and our team's expertise, every stroke of the machine is a testament to our commitment to perfection.

Components pass through stringent assembly and testing phases, assuring that they not only fit like pieces of a puzzle but also perform optimally under real-world conditions.

Richconn's team comprises experts who not only understand the intricacies of OEM CNC machining but also possess a deep comprehension of the industries we serve.

Richconn views clients as partners in progress. The success lies in your satisfaction.

Ready to Elevate Your Precision Components?

Tap Below to Transform Your Vision into Reality >>>

In the landscape of modern manufacturing, precision machining emerges as the transformative force that bridges innovation and meticulous craftsmanship. With the fusion of cutting-edge technology and skilled expertise, precision machining shapes raw materials into components of unrivaled accuracy and detail. Richconn, as one of the great representatives in precision machining services, embodies this commitment to perfection. Start your project NOW and get an instant quote today!

Laser Etching: Guide and Comprehensive ContentOctober 8, 2023Laser Etching is a high-precision processing technique widely used to create fine patterns, markings, and engravings on a variety of materials. It utilizes the high energy of a laser beam to gradually remove the surface of a material to create depth, patterns or text.view

Laser Etching: Guide and Comprehensive ContentOctober 8, 2023Laser Etching is a high-precision processing technique widely used to create fine patterns, markings, and engravings on a variety of materials. It utilizes the high energy of a laser beam to gradually remove the surface of a material to create depth, patterns or text.view What is the Powder Bed Fusion Process?November 28, 2023Powder bed fusion (PBF) is a type of additive manufacturing, or 3D printing, that uses a heat source, such as a laser or an electron beam, to melt and fuse material powder together to create solid parts.view

What is the Powder Bed Fusion Process?November 28, 2023Powder bed fusion (PBF) is a type of additive manufacturing, or 3D printing, that uses a heat source, such as a laser or an electron beam, to melt and fuse material powder together to create solid parts.view Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view

Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view Quenching, Tempering, Normalizing, Annealing, Can You Tell the Difference?October 23, 2023In order to make the metal workpiece has the required working performance, heat treatment process is often essential. Heat treatment process generally includes heating, holding, cooling three processes, due to the different processes are divided into quenching, tempering, normalizing, annealing, etc., do you distinguish?view

Quenching, Tempering, Normalizing, Annealing, Can You Tell the Difference?October 23, 2023In order to make the metal workpiece has the required working performance, heat treatment process is often essential. Heat treatment process generally includes heating, holding, cooling three processes, due to the different processes are divided into quenching, tempering, normalizing, annealing, etc., do you distinguish?view About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view

About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

EN

EN

ru

ru