With the development and advancement of science and technology and the innovation of mechanical parts processing technology, the society has put forward more stringent requirements for medical devices in terms of deburring and polishing surface accuracy, surface asepticization, and compatibility with implanted materials.

Facing this challenge, leading medical device companies are looking for more reliable and efficient surface finishing processes to improve the quality and added value for orthopedic and other products. In this article, we will introduce four surface finishing processes for orthopedic medical devices and implants.

Orthopedic implants mainly include bone-jointed implants and joint implants, such as fixing implants in the spine, providing artificial joints, etc., while hip and knee implants, etc.. Based on the clinical situation of different patients, the roundness, size and surface roughness of the artificial hip joint in orthopedic implants are extremely important quality indicators.

According to relevant data from Australia, the 5-year cumulative revision rate after hip surface replacement is significantly higher. Improving the fatigue resistance of the material requires the rough and fine machining processes of grinding, honing and final polishing of the surface treatment technology to achieve sufficiently excellent surface quality and dimensional accuracy.

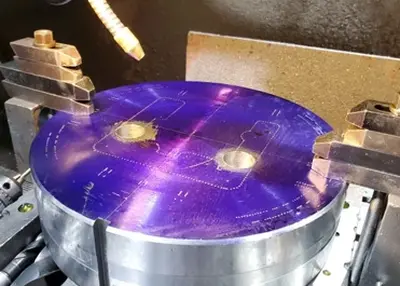

Precision grinding technology uses grinding wheels to grind blanks and grind raw materials to a certain dimensional accuracy, which also facilitates the next step of honing on the basis of ensuring reduced errors. And honing can realize mirror-like finish and uniform and consistent shape and position tolerance.

Implants are not allowed to have tiny burrs or imperfections, its surface roughness may induce the risk of infection, but also affect the speed of compatibility and healing with human tissues.

Polishing, as the last finishing process, is particularly important in hip surgery, as it aims to reduce the surface roughness of the implant, decrease the coefficient of friction and wear, and remove burrs, abrasions, knife marks, and other traces of machining.

Existing technologies can achieve the absence of chips, burrs, and micro cracks without changing the organizational structure of the metal material. Such as high-precision electrolytic machining (PECM) under the non-contact metal removal process, the surface roughness of up to Ra 0.03μm, but also to achieve both machining accuracy and repeatability of low-micron level of burr-free workpiece processing, the real mirror-like smoothness and uniformity of the degree.

There are two hard indicators for cleaning technology, one is to ensure the cleanliness and sterility of surgical instruments to avoid infection complications; the other is to prolong the service life of medical devices, such as orthopaedic instruments, bone prosthesis, artificial joints, orthopaedic plates and so on.

Commonly used cleaning technology is divided into manual cleaning and machine cleaning, ordinary medical devices are generally cleaned by automatic cleaning machine and ultrasonic cleaning. Part of the surface porous, complex structure of medical devices, traditional water washing is difficult to achieve the desired effect, can be used ultrasonic cleaning.

Taking artificial hip replacement as an example, aseptic loosening is the main reason for its failure and need for renovation. It is necessary to improve the compatibility of the implanted material in order to coexist with the bone tissue for a long time, which will involve the coating technology of promoting osteointegration ability and antimicrobial, in order to improve the product performance and life cycle of the osteoarthritic prosthesis.

Coatings aimed at promoting osteointegration can provide an ideal material interface to participate in the bone repair process through the use of specific biofunctional biomolecule coatings that allow osteoblasts to be directly immobilized on the biocompatible material. The coating technology that focuses on antimicrobial properties is to carry a certain bactericidal effect by inhibiting the growth of bacteria on the basis of satisfying the special microstructure of the bone surface.

Commonly used coatings are mainly the bone-like material hydroxyapatite (HA) and the metallic material tantalum. Hydroxyapatite (HA) is biocompatible but has relatively poor mechanical properties, and zirconium oxide and titanium oxide are usually added in the form of composite coatings to enhance strength. Tantalum, on the other hand, is highly resistant to wear and corrosion, and has been used successfully in a large number of clinical applications. Porous Tantalum is known as the "metal bone trabeculae", and is currently the most ideal material for use in articular surfaces.

The implanted medical devices used in surgery belong to the high-end products of Class III medical devices, which are also medical high-value consumables. Due to the special and strict production materials, the demand for complex orthopaedic parts is also changing dramatically along with the improvement of medical level. The development of precise machining technology will continue to meet the demand for accurate and intelligent products of implantable parts and professional medical devices in orthopedic medical treatment, and promote the healthy development of medical device industry.

As a leading precision machining company in China, Richconn is committed to providing excellent medical CNC machining services as well as precision surface treatment services. We understand that the medical industry has extremely high requirements for surface accuracy and sterility, especially in the orthopedic medical field. By introducing innovative surface preparation technologies, we help medical device companies improve product quality and value and meet stringent quality standards.

At Richconn, we offer a variety of precision machining technologies, including precision grinding, deburring and polishing, cleaning and sterilizing, and surface coating technologies. These technologies not only improve the surface quality and dimensional accuracy of orthopedic medical devices, they also increase device compatibility and longevity, thereby reducing the risk of infection and complications.

Whether you need highly precise orthopedic implants or other medical devices, Richconn's team of professionals will provide you with customized solutions to ensure your products meet the highest standards. Choose Richconn for superior quality and reliable partners, and contribute to the health of the medical device industry.

Quenching, Tempering, Normalizing, Annealing, Can You Tell the Difference?October 23, 2023In order to make the metal workpiece has the required working performance, heat treatment process is often essential. Heat treatment process generally includes heating, holding, cooling three processes, due to the different processes are divided into quenching, tempering, normalizing, annealing, etc., do you distinguish?view

Quenching, Tempering, Normalizing, Annealing, Can You Tell the Difference?October 23, 2023In order to make the metal workpiece has the required working performance, heat treatment process is often essential. Heat treatment process generally includes heating, holding, cooling three processes, due to the different processes are divided into quenching, tempering, normalizing, annealing, etc., do you distinguish?view Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view

Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view What Is Die Casting?March 7, 2024Do you know about die cast definition? This article introduces the definition, process, types, and everything you need to know about die cast.view

What Is Die Casting?March 7, 2024Do you know about die cast definition? This article introduces the definition, process, types, and everything you need to know about die cast.view What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view

What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view What Is Extruded Aluminum And How Does It Work?February 1, 2024Aluminum extrusion has been increasingly popular in making many types of products. What is aluminum extrusion? How does it work? Read this article about the extrusion process.view

What Is Extruded Aluminum And How Does It Work?February 1, 2024Aluminum extrusion has been increasingly popular in making many types of products. What is aluminum extrusion? How does it work? Read this article about the extrusion process.view

EN

EN

ru

ru