Bakelite is a synthetic material that was invented in the early 20th century by Leo Baekeland, a Belgian-American chemist. Bakelite is considered to be the first true plastic, as it was the first material that was not derived from natural sources, such as cellulose, rubber, or horn.

Bakelite is a thermosetting resin, which means that it can be molded into various shapes and forms when heated, but it cannot be melted or reshaped once it is cured. Bakelite has many properties that make it suitable for a wide range of applications, such as electrical insulation, heat resistance, chemical resistance, and durability. Bakelite is also known for its distinctive appearance, which can range from dark brown to bright colors, and its characteristic sound, which is a deep clunk when tapped. Bakelite is a historical and cultural icon, as it represents the dawn of the modern plastics industry and the emergence of mass production and consumerism. Bakelite products, such as jewelry, radios, telephones, and kitchenware, are highly collectible and valued by antique enthusiasts.

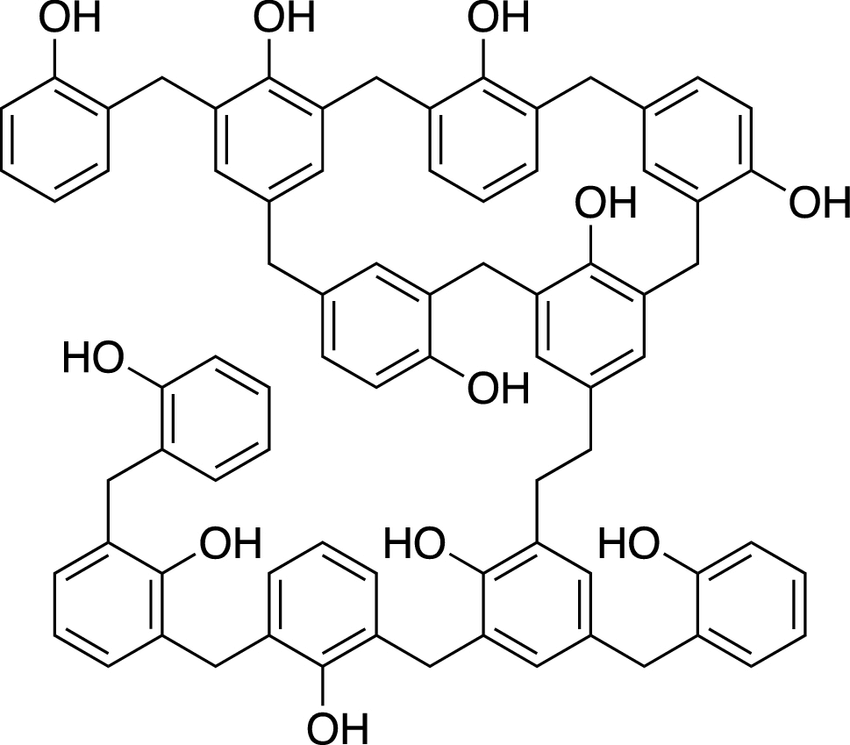

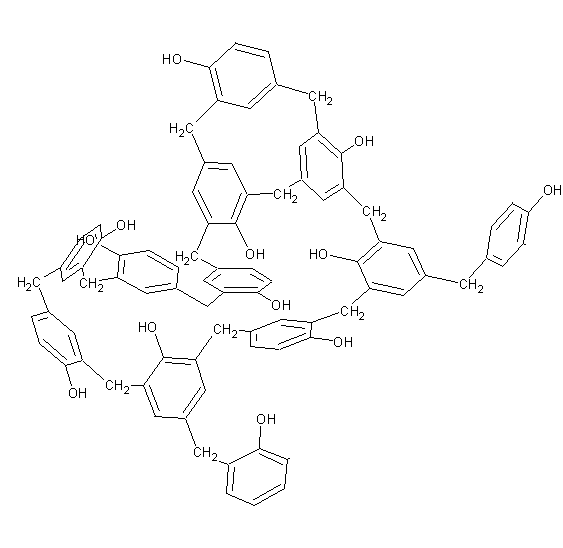

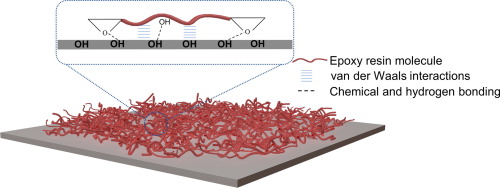

Bakelite is often confused with other types of plastics, especially those that are also made from phenol and formaldehyde, such as phenolic resins and melamine. However, Bakelite is different from these plastics in several ways. First, Bakelite is the original and trademarked name for the resin that Baekeland patented in 1909, while other plastics are generic names for similar but not identical materials. Second, Bakelite is a thermoset plastic, while most other plastics are thermoplastics. Thermoset plastics are irreversibly cured by heat and pressure, and they cannot be remelted or recycled. Thermoplastics, on the other hand, can be softened and reshaped by heating, and they can be reused or recycled. Third, Bakelite has a unique chemical structure that gives it its characteristic properties and appearance. Bakelite is composed of cross-linked phenol-formaldehyde polymers, which form a rigid and dense network. Bakelite can be modified by adding various fillers, such as wood, asbestos, or bronze, to enhance its strength, hardness, or color. Bakelite can also be coated with different resins, such as urea-formaldehyde or alkyd, to improve its surface finish or resistance to moisture.

Bakelite can be classified into different types based on their composition, structure, and color. The main types of Bakelite are:

This is the original and most common type of Bakelite, which is made from phenol and formaldehyde. PF resin can be either resol or novolac, depending on the ratio of phenol to formaldehyde. Resol resin has a higher ratio of formaldehyde and can be cured without a catalyst, while novolac resin has a lower ratio of formaldehyde and requires a catalyst, such as hexamine, to cure. PF resin can be molded into various shapes and forms, such as sheets, rods, tubes, and blocks. PF resin is usually dark brown or black in color, but it can also be dyed with organic pigments or inorganic oxides to produce different colors, such as red, green, blue, or yellow. PF resin is widely used for electrical insulation, heat resistance, and mechanical strength.

This is a type of Bakelite that is made by adding various fillers, such as wood, asbestos, or bronze, to PF resin. The fillers can improve the properties of Bakelite, such as hardness, toughness, or thermal conductivity. FP resin can also be molded into various shapes and forms, such as sheets, rods, tubes, and blocks. FP resin is usually dark brown or black in color, but it can also be dyed with organic pigments or inorganic oxides to produce different colors, such as red, green, blue, or yellow. FP resin is widely used for electrical insulation, heat resistance, and mechanical strength, as well as for decorative purposes, such as jewelry, buttons, or handles.

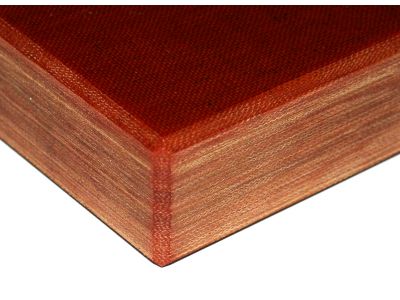

This is a type of Bakelite that is made by laminating layers of paper, fabric, or glass fiber impregnated with PF resin. The layers are pressed together under heat and pressure to form a solid sheet or tube. LP resin can have various patterns, textures, or colors, depending on the type and arrangement of the layers. LP resin is widely used for electrical insulation, heat resistance, and mechanical strength, as well as for decorative purposes, such as countertops, furniture, or wall panels.

This is a type of Bakelite that is made by coating PF resin or FP resin with another resin, such as urea-formaldehyde or alkyd. The coating can improve the surface finish or resistance to moisture of Bakelite. CP resin can also be molded into various shapes and forms, such as sheets, rods, tubes, and blocks. CP resin can have various colors, depending on the type and color of the coating. CP resin is widely used for electrical insulation, heat resistance, and mechanical strength, as well as for decorative purposes, such as kitchenware, tableware, or toys.

There are many ways to test Bakelite for authenticity, and some of them are as follows:

This is one of the easiest and safest methods to identify Bakelite. You just need to dip your item into hot water or create friction on the item by rubbing it on a piece of clothing to create some heat. Then, you need to smell the item. If it is true Bakelite, it should have a chemical smell of formaldehyde, which is similar to paint remover or varnish.

This is another simple method to identify Bakelite. You just need to compare the weight of your item with another type of plastic of approximately the same size. Bakelite should feel heavier and more substantial than other plastics, such as celluloid.

This is another easy method to identify Bakelite. You just need to gently tap two pieces of Bakelite together and listen to the sound they make. Bakelite should produce a deeper clunk sound, rather than a clink sound that other plastics make.

This is a more reliable and accurate method to identify Bakelite, but it requires a special polish called Simichrome, which is available online or in some hardware stores. You just need to take a small amount of polish on a cotton swab and rub it on a test spot on the item, such as the inside of a bracelet or the back of a brooch. If the cotton swab turns a deep tan or tobacco brown color, it means that the item is Bakelite.

This is another reliable and accurate method to identify Bakelite, but it requires a household cleaner called 409, which is available in most supermarkets or online. You just need to spray a small amount of 409 on a cotton swab and rub it on a test spot on the item, such as the inside of a bracelet or the back of a brooch. If the cotton swab turns a yellow tone, it means that the item is Bakelite.

This is another reliable and accurate method to identify Bakelite, but it requires baking soda, which is available in most supermarkets or online. You just need to dip a cotton swab into baking soda and rub it on a test spot on the item, such as the inside of a bracelet or the back of a brooch. If the cotton swab turns a yellow tone, it means that the item is Bakelite.

These are some of the common methods to test Bakelite for authenticity, but there are also other methods that can be used, such as the appearance, the smell, the texture, and the reaction to light.

Bakelite boasts diverse applications across multiple fields and industries, playing a pivotal role in:

Renowned for its exceptional properties, Bakelite stands as a foundational material in the creation of various electrical and electronic components. These encompass switches, sockets, plugs, connectors, circuit boards, transformers, capacitors, resistors, coils, relays, and radios. Its remarkable attributes, including outstanding electrical insulation, heat resistance, and chemical durability, render Bakelite highly suitable for these purposes. Moreover, it finds utility in crafting telephones, phonographs, cameras, and analogous devices reliant on electrical or electronic functionalities.

In the domains of automotive and aerospace, Bakelite emerges as a cornerstone material for a spectrum of components. From brake pads and clutch plates to distributor caps, spark plugs, steering wheels, dashboard panels, and instrument panels, Bakelite’s commendable heat resistance, mechanical robustness, and durability render it an optimal choice. Its application extends further to the production of aircraft parts like propellers, wings, and fuselage, highlighting its versatile utility.

Within industrial and construction realms, Bakelite serves as an indispensable material for a myriad of components, encompassing gears, bearings, bushings, valves, pipes, fittings, gaskets, seals, and pumps. Its exceptional mechanical strength, hardness, and wear resistance render it a prime selection for these applications. Additionally, Bakelite contributes to the creation of construction materials, including roofing, flooring, and insulation, owing to its resilient properties.

Renowned for its distinctive visual appeal, Bakelite reigns as a primary choice for art and design endeavors. From jewelry like buttons, beads, brooches, bracelets, necklaces, earrings, rings, and cufflinks, Bakelite’s unique aesthetic attributes make it an ideal medium. Its versatility in color, shape, and patterns adds allure and fashionability to these creations. Furthermore, Bakelite extends its influence to the fabrication of decorative items such as lamps, clocks, vases, sculptures, and figurines, contributing to their visual charm and appeal.

Bakelite stands as the pioneering synthetic plastic, marking a pivotal milestone in material history with unparalleled influence. Its diverse array of properties renders it an ideal choice across a broad spectrum of applications, boasting attributes like electrical insulation, heat and chemical resistance, mechanical robustness, and enduring durability. Notably, Bakelite’s distinctive appearance spans from rich, dark browns to vibrant hues, accompanied by its characteristic deep clunk when tapped, creating a sensory identity all its own.

This material transcends mere functionality, assuming a profound historical and cultural significance. Symbolizing the advent of the modern plastics industry and the rise of mass production and consumerism, Bakelite has become an icon. Its products, from jewelry to radios, telephones, and kitchenware, hold immense value and are cherished by collectors passionate about antiques.

Despite its legacy, Bakelite maintains relevance in contemporary applications like brake pads, circuit boards, and countertops. However, newer and more advanced plastics like nylon, polyethylene, and polystyrene have largely supplanted its extensive usage. Nevertheless, Bakelite's enduring legacy reverberates through society, culture, and the environment, leaving an indelible imprint that continues to shape our collective narrative.If you want to know about bakelite machining services, you can contact Richconn. As a precision manufacturing company, we can provide you with bakelite machining services.

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view CNC Motion Control and Three Common TypesOctober 20, 2023Many CNC machines can be left unattended throughout the machining cycle, freeing the operator for other tasks. This benefit allows CNC users to provide several side effects, including reduced operator fatigue, errors due to operator error, and consistent and predictable machining times for each workpiece.view

CNC Motion Control and Three Common TypesOctober 20, 2023Many CNC machines can be left unattended throughout the machining cycle, freeing the operator for other tasks. This benefit allows CNC users to provide several side effects, including reduced operator fatigue, errors due to operator error, and consistent and predictable machining times for each workpiece.view Electrophoretic Surface Treatment Process Characteristics and Main CharacteristicsSeptember 16, 20221. Characteristics of electrophoresis surface treatment processElectrophoretic paint film has the advantages of full, uniform, flat and smooth coating. The hardness, adhesion, corrosion resistance, im...view

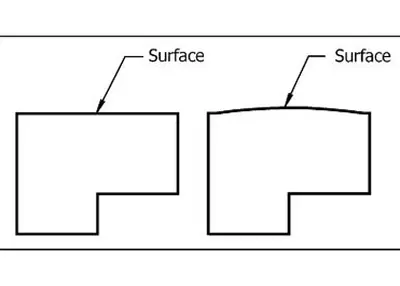

Electrophoretic Surface Treatment Process Characteristics and Main CharacteristicsSeptember 16, 20221. Characteristics of electrophoresis surface treatment processElectrophoretic paint film has the advantages of full, uniform, flat and smooth coating. The hardness, adhesion, corrosion resistance, im...view Exploring the Essence of Flatness: A Comprehensive InsightNovember 21, 2023In a world where precision and accuracy reign supreme, understanding the concept of flatness becomes paramount. Whether you're in engineering, mathematics, or the manufacturing sector, the significance of achieving optimal flatness cannot be overstated. Join me on a journey as we delve into the nuances and practical applications of this crucial aspect across various domains.view

Exploring the Essence of Flatness: A Comprehensive InsightNovember 21, 2023In a world where precision and accuracy reign supreme, understanding the concept of flatness becomes paramount. Whether you're in engineering, mathematics, or the manufacturing sector, the significance of achieving optimal flatness cannot be overstated. Join me on a journey as we delve into the nuances and practical applications of this crucial aspect across various domains.view Types And Characteristics Of FastenersOctober 24, 2023Screws the most common fasteners used to create removable threaded connections in household appliances, industrial equipment, transportation, building structures and other machines and mechanisms. Consider the varieties of bolts, the materials of construction, and the characteristics of their manufacture.view

Types And Characteristics Of FastenersOctober 24, 2023Screws the most common fasteners used to create removable threaded connections in household appliances, industrial equipment, transportation, building structures and other machines and mechanisms. Consider the varieties of bolts, the materials of construction, and the characteristics of their manufacture.view Types of Springs | Guidelines, Spring Types, and ApplicationsOctober 18, 2023Springs play a crucial role in various products, providing motion and shock absorption. This article will show you different types of springs and how to choose the right one.view

Types of Springs | Guidelines, Spring Types, and ApplicationsOctober 18, 2023Springs play a crucial role in various products, providing motion and shock absorption. This article will show you different types of springs and how to choose the right one.view