Some companies seek a quality precision manufacturer with the best matching services. Nowadays, there are lots of CNC manufacturers to choose from. The problem is how to pick out the right CNC manufacturer. In this article, we take a look at tips for choosing the right CNC machining manufacturer.

The first tip for selecting the best precision CNC machine manufacturer is to choose one with extensive experience. In other words, look for a partner that has been in the industry for a significant period. This does not mean that newer precision machining services cannot provide quality work. However, those with a wealth of manufacturing experience, which is acquired over the years, tend to be more reliable and capable. An experienced manufacturing service not only possesses in-depth knowledge of production processes but also has a solid reputation in terms of customer service and product fulfillment.

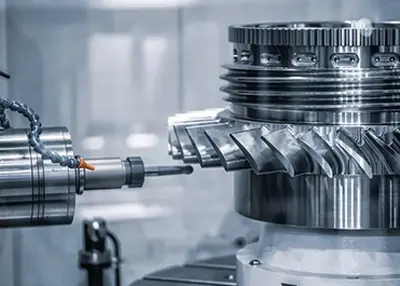

The second aspect to consider when searching for CNC machine manufacturers is the technologies and systems they offer. This is crucial for several reasons. Firstly, if your part necessitates five-axis CNC machining, it is pointless to engage with a service that only has three-axis machines. Instead, check the service's machine roster, typically available on their website, to ensure they possess the necessary manufacturing equipment.

Secondly, and particularly important if you have strict time constraints, determine how many machining systems the precision machining shop has in operation. A CNC manufacturer with only two machines might not be able to offer the same quick turnaround times as a larger service with hundreds of machines in operation.

At Richconn, for instance, we are proud of our extensive CNC machining capabilities, driven by ten types of CNC machining, such as 3, 4, and 5-axis CNC machines and other supporting equipment.

This tip is more important for certain applications than others, but it is a good way to determine how established a precision machining shop is. For instance, if you are seeking to manufacture parts for aerospace applications, it is important to go for the highest quality CNC machine manufacturer. You must ensure that the production facility has the required certifications for the tightly regulated industry. Similarly, the production partner should have medical-grade facilities and certifications if you are ordering medical devices or components.

Beyond these specific circumstances, there are other types of certification to look out for, including environmental certificates, as well as documentation from material suppliers, and quality assurance certifications.

Another critical factor to examine in choosing precision machining services is lead times. Basically, you want to know whether a manufacturing partner can machine and deliver a part within your required timeframe. In most cases, quality CNC machine manufacturer will list their usual turnaround times; however, these vary based on the scale and complexity of your manufacturing job.

In Richconn, our highly skilled and experienced teams follow up on the orders, ensuring that you receive the best metal parts on time for your project.

In the past, finding a manufacturing service partner involved time-consuming tasks like searching through phonebooks, making numerous calls, and gathering cost estimates. Additionally, language barriers could pose challenges when working with international precision manufacturing companies. However, thanks to advancements in technology, communication has become easier and more efficient. Within an hour, you can now reach out to multiple rapid prototyping services online to obtain quotes. Despite the convenience provided by the Internet, it is still crucial to assess the quality of communication offered by a machining service. A prompt and responsive manufacturing service that promptly addresses your emails or phone calls and is available to address any inquiries or concerns is an encouraging sign. Maintaining effective communication between customers and manufacturing service providers is essential, as it contributes to the success of your production job and fosters continued collaboration.

Location plays a significant role when choosing a precision machining shop. While there are advantages to working with local machining services, such as simplifying shipping and logistics, it may also be worthwhile to consider a Chinese CNC machining manufacturer. CNC Machine Manufacturers in China can sometimes offer lower production costs due to cheaper raw materials and labor expenses, making them a viable option for those on strict manufacturing budgets. Additionally, certain manufacturers, like Richconn, have the capability to meet tight turnaround times by leveraging robust logistic chains and reliable shipping partners.

Last but not least, cost is the most important factor in choosing the right CNC machine manufacturer. Of course, you want to find a manufacturer that offers prototype machining or machining parts manufacturing beyond your expectations at a lower price. Richconn offers a comparative price than many other companies. This cost advantage can be advantageous for businesses looking to produce high-quality products at a competitive price.

Finding the right CNC manufacturers is crucial for the success of your project. Once you find the right manufacturing partner, you can establish a long-term working relationship. It is important to find a manufacturer that aligns with your specific needs.

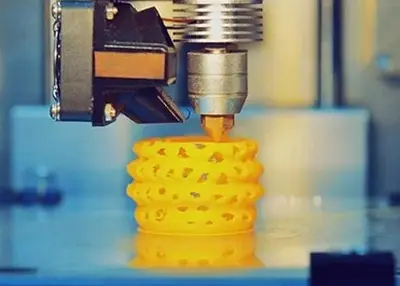

Richconn is a well-established rapid prototyping service that specializes in precision machining. We take pride in manufacturing parts and products that meet our clients' expectations. Our range of services includes sheet metal service, 3D printing, die casting, and finishing services. Contact us today or receive an instant quote for your project.

Currently, there are numerous precision machining shops available, making it challenging to choose the right one. The success or failure of a company often relies on making the correct decision regarding precision machining services. We have outlined seven of the most relevant factors to consider, which apply to both local and international precision manufacturing services. Good news! Richconn fulfills all these criteria.

Contact us to get a competitive price NOW!

Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view

Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view Understanding Steel Material for Custom Prototyping: Properties, Grades, and ApplicationsMarch 14, 2024Let’s explore the diverse properties, grades and uses of steel material in prototyping, from its melting point to its versatility across different industry sectors.view

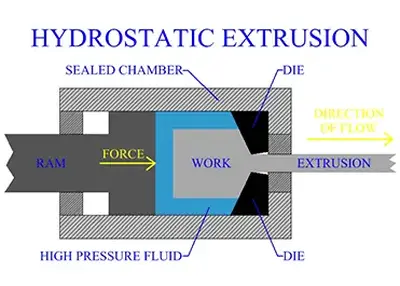

Understanding Steel Material for Custom Prototyping: Properties, Grades, and ApplicationsMarch 14, 2024Let’s explore the diverse properties, grades and uses of steel material in prototyping, from its melting point to its versatility across different industry sectors.view Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view Resin Materials: What They Are, How They Differ, and How to Use ThemDecember 8, 2023Resin materials are synthetic or natural substances that can be molded or shaped into various forms. They are widely used in many industries and applications, such as art, crafts, jewelry, furniture, electronics, medical, aerospace, etc.view

Resin Materials: What They Are, How They Differ, and How to Use ThemDecember 8, 2023Resin materials are synthetic or natural substances that can be molded or shaped into various forms. They are widely used in many industries and applications, such as art, crafts, jewelry, furniture, electronics, medical, aerospace, etc.view Material Properties in More DetailOctober 18, 2023The functionality of a part is largely dependent on obvious factors such as shape, size, wall thickness, joints, etc. Less obvious, but equally important, are the properties of the material from which it is injection molded, CNC machined, or 3D printed (cut, bent, formed, etc.).view

Material Properties in More DetailOctober 18, 2023The functionality of a part is largely dependent on obvious factors such as shape, size, wall thickness, joints, etc. Less obvious, but equally important, are the properties of the material from which it is injection molded, CNC machined, or 3D printed (cut, bent, formed, etc.).view What Is Prototype Manufacturing? Process, Benefits, and Vital TipsOctober 25, 2023A good understanding of prototype manufacturing will help you make the best choice for your project. Learn more about it from this passage.view

What Is Prototype Manufacturing? Process, Benefits, and Vital TipsOctober 25, 2023A good understanding of prototype manufacturing will help you make the best choice for your project. Learn more about it from this passage.view

EN

EN

ru

ru