CMM is widely used in machinery, electronics, instrumentation, plastics and other industries. CMM is one of the most effective methods of measuring and obtaining dimensional data, because it can replace a variety of surface measuring tools and expensive combination of gauges, and reduce the time required for complex measurement tasks from hours to minutes, which is the effect of other instruments and can not be achieved.

Coordinate measurement in the coaxiality detection is often encountered in our measurement work, with the three coordinates for coaxiality detection is not only intuitive and convenient, three yuan, 2.5 times the yuan and the three coordinates of the measurement results of high precision, and good repeatability.

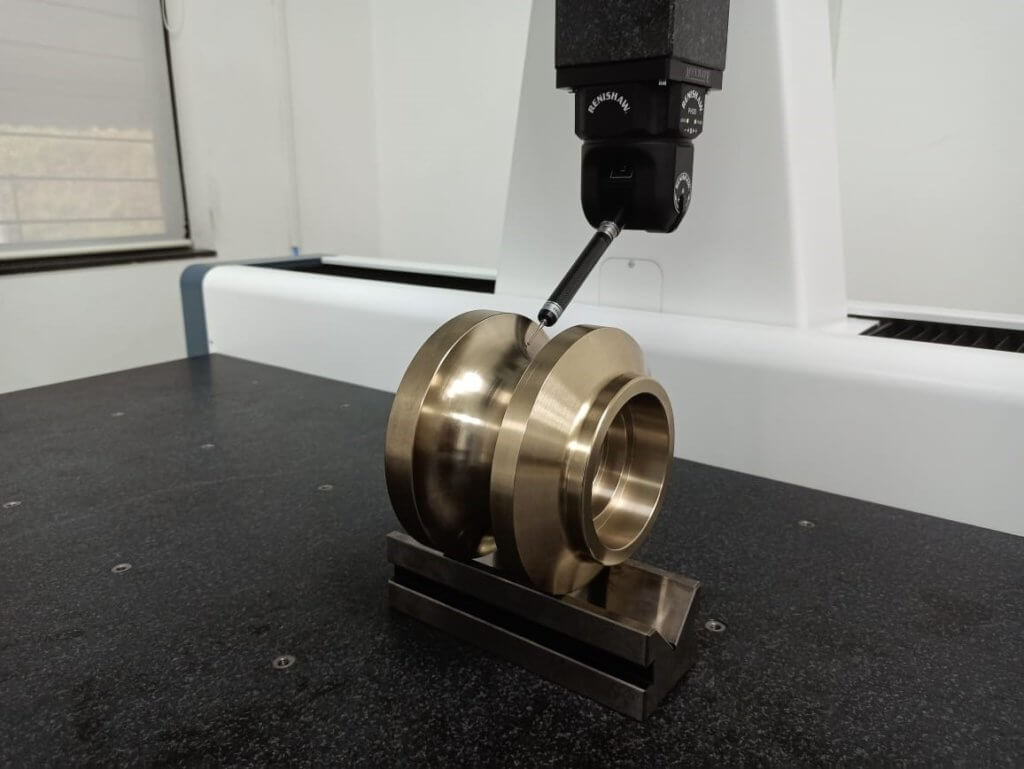

The function of a CMM is to evaluate dimensional data quickly and accurately, providing the operator with useful information about the state of the production process, which is very different from all manual measuring devices. By placing the object to be measured in the coordinate measuring space, the coordinate positions of the measuring points on the object can be obtained, and based on the spatial coordinate values of these points, the geometric dimensions, shape and position of the object to be measured can be calculated.

CMM is generally composed of the following parts:

1, host mechanical system (X, Y, Z axis or other);

2, measuring head system;

3, electrical control hardware system;

4, data processing software system (measurement software);

Coordinate measuring machine referred to as CMM, since the mid-sixties since the first three coordinate measuring machine, with the progress of computer technology and electronic control systems, detection technology, for measuring machines to high precision, high speed direction provides strong technical support.

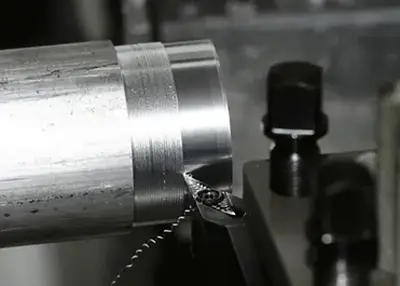

CMM according to the measurement method can be divided into contact measurement and non-contact measurement and contact and non-contact measurement, contact measurement is often used to measure machined products and compression molding products, metal films and so on. In this paper, we take the contact measuring machine as an example to illustrate several methods of scanning the surface of an object to obtain data points, which can be used to analyze the processing data and also provide original information for reverse engineering technology. Scanning refers to the use of the measuring machine application software in a specific area of the surface of the object to be measured for data point acquisition. This area can be a line, a facet, a cross-section of the part, a curve of the part, or a circumference at a certain distance from the edge. The type of scanning is related to the measurement mode, the type of probe, the availability of CAD files, etc. The status button (Manual/DCC) determines the "scanning" option available on the screen. If you are measuring in DCC mode and have a CAD file, then the scanning options are "open line", "closed line", "face sheet", "section" and "perimeter". "Open Line", "Closed Line", "Side Sheet", "Section" and "Perimeter" (Scanning.). If the measurement is made by DCC and only wireframe CAD files are available, then OPEN LINEAR, CLOSED LINEAR and PATCH are available. " (PATCH) scanning modes. In manual measurement mode, only the basic MANUL TTP SCAN method can be used. If in manual measurement mode and the probe is a rigid probe then the available options are FIXED DELTA, VARIABLE DELTA, TIME DELTA, TIME DELTA and TIME DELTA. "The available options are FIXED DELTA, VARIABLE DELTA, TIME DELTA and BODY AXIS SCAN.

Three coordinates in the national standard coaxiality tolerance zone is defined as the diameter tolerance for the value of t, and 3D image measurement and coordinate measuring machine reference axis coaxial cylindrical surface within the there area. It has the following three control elements: ① axis and axis; ② axis and common axis; ③ center of the circle and center of the circle.

2.5 times in the main factors affecting the coaxiality of the measured element and the reference element of the center of the circle position and the direction of the axis, especially in the direction of the axis. Such as the measurement of two cross-sectional circles on the reference cylinder, using its line as the reference axis. Measure two section circles on the measured cylinder as well, construct a straight line, and then calculate the coaxiality. Assuming that the distance between the two sections of the reference is 10 mm, the distance between the first section of the reference and the first section of the column under test is 100 mm, if the location of the center of the second section of the reference circle and the center of the circle of the first section of the circle has a measurement error of 5 μm, then the extension of the reference axis to the first section of the column under test has been deviated from the 50 μm (5 μm x 100 ÷ 10), at this time, the quadratic element and the 2.5 elements even though The measured cylinder is completely coaxial with the datum, the result will be 100μm error (coaxiality tolerance value for the diameter, 50μm is the radius).

The Z-axis balance of the measuring machine is divided into heavy hammer and pneumatic balance, which is mainly used to balance the weight of the Z-axis and make the Z-axis drive smoothly. If the pneumatic balance switch is moved by mistake, the Z-axis will be unbalanced. Methods of handling:

1) Turn the angle of the head to 90,0 to avoid touching the probe during operation.

2) Press the "Emergency Stop" switch.

3) One person holds the Z-axis with both hands and pushes and pulls it upward and downward to feel the balancing effect.

4) One person adjusts the air pressure balance valve, each time the adjustment amount is small, two people cooperate to adjust the Z-axis balance to the same feeling of upward and downward.

The end-of-travel switch is used for end-of-travel protection and HOME. End-of-travel switches are usually contact switches or photoelectric switches. The switch is most likely to change position when the shaft is pushed by hand, resulting in poor contact. The switch position can be adjusted appropriately to ensure good contact. Photoelectric switch should pay attention to check the position of the insert is normal, and often remove the dust to ensure that it works properly.

The correct use of CMM plays a key role in its service life and accuracy, and the following issues should be noted:

1, before lifting the workpiece, the probe should be returned to the origin of the coordinates, to reserve a larger space for the lifting position; the workpiece should be lifted smoothly, and must not hit any components of the CMM.

2, correctly install the parts, before installation to ensure that the parts meet the isothermal requirements of the measuring machine.

3, the establishment of a correct coordinate system, to ensure that the built coordinate system in line with the requirements of the drawings, in order to ensure that the measured data is accurate.

4, when the program is programmed to run automatically, to prevent interference between the probe and the workpiece, so we need to pay attention to increase the inflection point.

5, for some large and heavy molds, fixtures, measurement should be lifted off the table in a timely manner after the end of the table, in order to avoid a long time in the table in the bearing state.

Coordinate measuring machine has a variety of mechanical components, we need daily maintenance is the transmission system and gas system components, maintenance frequency should be based on the environment in which the measuring machine to decide. Generally in the environment is better in the fine measurement of the measuring machine in the room, the recommended routine maintenance every three months, and if the use of the environment is more dusty, measurement of the temperature and humidity of the room can not fully meet the requirements of the measuring machine using the environment, it is recommended to carry out routine maintenance once a month, the routine maintenance of the measuring machine, should be aware of the factors that affect the measuring machine:

(1) to choose the right air compressor, it is best to have another storage tank, so that the air compressor has a long working life and stable pressure.

(2) The starting pressure of the air compressor must be greater than the working pressure.

(3) When turning on the measuring machine, turn on the air compressor first, and then turn on the power.

Since compressed air plays a very important role in the normal operation of the measuring machine, it is very important to repair and maintain the air circuit. Among them are the following main items:

Check the piping and filters before using the measuring machine every day and drain water and oil from the filters and from the air compressor or storage tank.

Wipe the guide oil and dust every day to keep the air float guide in normal working condition.

Measurement machine room air conditioning should try to choose frequency conversion air conditioning. Inverter air conditioning energy-saving performance is good, the main thing is that the temperature control ability is strong. In the case of normal capacity, temperature control can be within ± 1 ℃.

As the air conditioner blowing out the wind temperature is not 20 ℃, so never let the wind blow directly onto the measuring machine. Sometimes the wind is turned to the wall or side to prevent the wind from blowing onto the measuring machine, resulting in a very large temperature difference with one side hot and one side cool in the machine room.

The installation of air conditioners should be planned so that the wind blows to the main location of the room, and the wind direction is upward to form a large circulation (not blowing to the measuring machine), and try to equalize the temperature in the room.

If possible, air ducts should be installed to send the air to the top of the room through the double orifice plate, and the return air outlet is in the lower part of the room. This makes the airflow irregular, which can make the temperature control of the machine room more reasonable.

The composition of the three coordinate measuring machine is relatively complex, mainly mechanical components, electrical control components, computer systems. Usually we use the coordinate measuring machine to measure the workpiece at the same time, but also pay attention to the maintenance of the machine in order to extend the service life of the machine. The following focuses on compressed air maintenance and guideway maintenance.

Since compressed air plays a very important role in the normal work of the CMM, it is very important to repair and maintain the air source. Among them are the following main items:

1, check the pipeline and filter before using the CMM every day, and release the water and oil in the filter and in the air compressor or air storage tank.

2, generally 3 months to clean the random filter and pre-filter cartridge. The cycle of poor air quality should be shortened. Because the filter element in the filter oil and water at the same time itself is also blocked by oil contamination, a little longer will make the actual working air pressure of the measuring machine is reduced, affecting the normal work of the CMM. Be sure to clean the filter element regularly.

Coordinate measuring machine guide rail is the benchmark of the measuring machine, only good maintenance of air floatation block and guide rail to ensure the normal work of the measuring machine. Coordinate measuring machine guide rail maintenance in addition to frequent wiping with alcohol and degreasing cotton, but also pay attention to not directly on the guide rail to place parts and tools. Especially granite guide rail, because of its brittle texture, any small bump will cause bruises, if not detected in time, the debris will hurt the air floatation block and guide rail. To develop good working habits, use cloth or rubber pads underneath to ensure the safety of the guide rail.

Wipe the guide rails after work is finished or after parts are on. Wipe the guide rail oil and dust every day to keep the air float guide rail in normal working condition.

Mainly used in machinery, automobile, aviation, military, furniture, tools prototype, machines and other small and medium-sized accessories, molds and other industries in the box, frame, gears, cams, worm gears, worm gears, blades, curves, surfaces, etc. Measurement, but also can be used for electronics, hardware, plastics, and other industries, can be the size of the workpiece, the shape and the shape of the positional tolerance of the precision testing, so as to complete the parts inspection, shape measurement, process control and other Tasks.

Coordinate measuring machine in the mold industry is widely used, it is a design and development, testing, statistical analysis of modern intelligent tools, but also mold products unparalleled quality and technical assurance of effective tools. Today's main use of CMM bridge measuring machine, gantry measuring machine, horizontal arm measuring machine and portable measuring machine. Measurement can be roughly divided into contact and non-contact two kinds.

If there is any deviation in the matching between the core cavity of the mold and the guide pillar and guide bush, the deviation value can be found out by CMM in order to correct it. After the core cavity contour of the mold is processed and formed, many inserts and local surfaces have to be processed and shaped by electrodes on the electric pulse, thus the quality of electrode processing and the quality of non-standard surfaces become the key to the quality of the mold. Therefore, it is indispensable to measure the shape of the electrode with CMM. CMM can be applied to the input of 3D digital mold, the finished mold and digital mold on the positioning, dimensions, related shape and position tolerance, curves, surfaces for measurement and comparison, the output of graphical reports, intuitive and clear reflection of the quality of the mold, so as to form a complete inspection report of the finished product of the mold. In some molds used for a period of time to be corrected for wear and tear, but no original design data (i.e., the number of molds), you can use the cross-section method to collect the point cloud, with the specified format output, probe radius compensation after modeling, so as to achieve the effect of repair as good as new.

When some surface contours are neither arcs nor parabolas, but irregular surfaces, we can use oil clay or plaster to make surfaces by hand as the base embryo. Then use three coordinate measuring machine to measure each cross-section on the intercept line, feature line and parting line, with the specified format output, probe radius compensation after modeling, in the process of modeling smooth curve, so as to design and manufacture a brand new mold.

Coordinate measuring machine with its high precision and high flexibility as well as excellent digital capabilities, has become an important means of modern manufacturing industry, especially mold industry design, development, processing and manufacturing and quality assurance.

First, the measuring machine can provide quality assurance for the mold industry, is the best choice for mold manufacturing enterprises to measure and inspect. The flexibility of the measuring machine in handling different jobs and its own high accuracy make it an arbiter. While providing dimensional data for process control, the measuring machine can provide additional performance such as incoming product inspection, calibration of machine tools, customer quality certification, gauge inspection, machining trials and optimization of machine settings. Highly flexible CMM can be configured in the shop floor environment, and directly involved in the mold processing, assembly, mold testing, mold repair stages, to provide the necessary inspection feedback, reduce the number of rework and shorten the mold development cycle, which ultimately reduces the cost of manufacturing molds and production into control.

Second, the measuring machine has a strong reverse engineering capability, is an ideal digital tool. Through the combination of different types of probes and different structural forms of measuring machines, can quickly and accurately obtain the three-dimensional data and geometric features of the surface of the workpiece, which is particularly useful for the design of molds, samples of the replication, repair of damaged molds. In addition, the measuring machine can be equipped with both contact and non-contact scanning probes and utilizes the powerful scanning functions provided by the PC-DMIS measuring software to reproduce CAD models of complex workpieces with free-form surface shape features. Without any conversion, it can be directly recognized and programmed by various CAD software, thus greatly improving the efficiency of mold design.

Specifically, in the mold manufacturing enterprises in the application of measuring machines to complete the design and inspection tasks, we must pay close attention to the choice of measurement reference, probe calibration and selection, the number of measurement points and measurement position planning, the establishment of the coordinate system, the impact of the environment, the impact of local geometric features, CNC control parameters and other factors. Each of these factors has an impact on the accuracy and efficiency of the measurement results.

A CMM is a measurement system that detects the three-dimensional coordinates of points on the surface of a workpiece through the relative movement of a probe system and the workpiece. By placing the object to be measured in the measuring space of the CMM, the contact or non-contact probing system is used to obtain the coordinate positions of the points on the object to be measured, and based on the spatial coordinate values of these points, the software performs mathematical operations to find out the geometric dimensions and shapes, and the position of the object to be measured. Therefore, CMM is characterized by high precision, high efficiency and versatility, and is the ideal solution to complete the geometric measurement and quality control of various automotive parts.

Automotive parts are characterized by high quality requirements, large batch sizes and different shapes. According to different types of parts measurement, mainly divided into three categories of boxes, complex shapes and curved surfaces, the configuration of each type of relative measurement system is not the same, the need to measure the system from the host, the detection system and the software for each other to support and select.

Engine is composed of many various shapes of parts, these precision parts of the manufacturing quality is directly related to the performance and life of the engine. Therefore, it is necessary to carry out very precise testing in the production of these parts to ensure the accuracy and tolerance fit of the product. In the modern manufacturing industry, high-precision integrated measuring machines are increasingly used in the production process, so that the goal and key to product quality is gradually transformed from the final inspection to the control of the manufacturing process, through the information feedback on the parameters of the processing equipment in a timely manner to adjust, so as to ensure product quality and stabilize the production process, improve production efficiency.

In the traditional choice of measurement methods, people mainly rely on two measurement means to complete the measurement of the box type workpiece and complex geometry of the workpiece, that is: through the CMM to perform the detection of the box type workpiece; through the special measurement equipment, such as special gear tester, special cam detection equipment to complete the measurement of complex geometry of the workpiece. Therefore, for enterprises engaged in the production of complex geometric workpieces, to complete the quality control of the above products enterprises not only need to configure the general measuring equipment, such as coordinate measuring machines, general standard gauges, gauges, but also need to configure special testing equipment, such as a variety of sizes and types of gears special testing equipment, cam testing equipment and so on. This often leads to the measurement department of the enterprise needs to configure more types of measurement equipment and measurement operations engaged in the measurement of professional inspectors, measurement equipment, the use of low, while the enterprise to bear a higher measurement of the training costs of personnel and the use of measurement equipment and maintenance costs; the enterprise can not be realized flexible, universal measurement and testing. Therefore, to reduce the cost of measurement, the training costs of measurement personnel, the use of measurement equipment and maintenance costs, to achieve the purpose of improving the efficiency of measurement and detection, so that enterprises have the production process of real-time quality control capabilities, which will be related to the enterprise's resilience in the market activities, to help enterprises to establish and maintain a good reputation in the market, has an important role to play in the decision.

Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view

Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view Achieve Stunning Automotive Finishes with CNC Powder CoatingFebruary 29, 2024In the world of automotive customization, achieving a flawless and long-lasting finish is essential. Whether you are a car enthusiast looking to give your vehicle a new look or a professional in the i...view

Achieve Stunning Automotive Finishes with CNC Powder CoatingFebruary 29, 2024In the world of automotive customization, achieving a flawless and long-lasting finish is essential. Whether you are a car enthusiast looking to give your vehicle a new look or a professional in the i...view How to Choose the Right CNC Machining Manufacturer?January 30, 2024Discover tips for selecting the CNC machining manufacturer. Learn about key criteria, including expertise, capabilities, lead times, warranty policies, etc.view

How to Choose the Right CNC Machining Manufacturer?January 30, 2024Discover tips for selecting the CNC machining manufacturer. Learn about key criteria, including expertise, capabilities, lead times, warranty policies, etc.view Navigating Internal Turning vs External TurningNovember 22, 2023Welcome to the world of precision engineering, where every turn counts. As a CNC machining enthusiast, I invite you on a journey to uncover the subtleties between internal turning and external turning - two pivotal techniques shaping the art of machining.view

Navigating Internal Turning vs External TurningNovember 22, 2023Welcome to the world of precision engineering, where every turn counts. As a CNC machining enthusiast, I invite you on a journey to uncover the subtleties between internal turning and external turning - two pivotal techniques shaping the art of machining.view CNC Machined Motorcycle Parts: Precision Craftsmanship by RichconnNovember 14, 2023Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!view

CNC Machined Motorcycle Parts: Precision Craftsmanship by RichconnNovember 14, 2023Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!view Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view

Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view