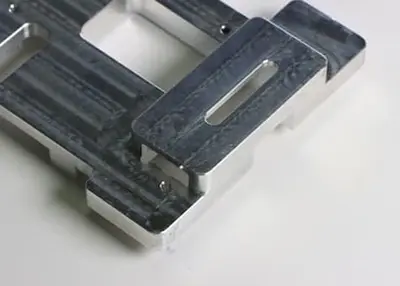

CNC machining is commonly used for complex designs, small products, and parts. Through CNC machine tools, a variety of parts can be machined more accurately.

With the rapid development of the automotive industry, the efficient, high-precision, and high-stability machining of complex major automotive components is an effective way to shorten product production cycles, improve enterprise efficiency and competitiveness. Automotive CNC machining technology makes rapid prototyping and manufacturing of complex automotive parts possible. At the same time, virtual manufacturing technology, flexible production technology and CNC technology integrated manufacturing technology are widely used in modern automotive manufacturing. The intelligent development of CNC manufacturing technology in the manufacturing process of automotive parts will become the development trend of the automotive manufacturing industry.

Automotive CNC machining technology can achieve rapid prototyping and manufacturing of complex automotive parts. Virtual manufacturing technology, flexible production technology, and integrated manufacturing technology with CNC technology are gradually being used in modern automobiles. It is widely used in manufacturing. The intelligent development of CNC systems in the manufacturing process of automotive parts will become the inevitable development trend of modern automotive manufacturing.

CNC operations include 3-axis and 5-axis machining and the use of electric tools for turning. These functions offer more ways to manipulate and manipulate materials in the machine, so that not only curves can be trimmed instead of right angles, but they are often more complex and can produce good results. It is no wonder that this has led to widespread use, including some key automotive parts.

Compared with manual labor, CNC machining CNC technology realizes the standardization and standardization of automotive parts manufacturing, laying the foundation for improving the production quality and start rate of automotive parts. CNC technology can provide a set of automation solutions for the manufacture of major automotive parts. During the machining process, it receives machining data based on industrial Internet and big data monitoring and remote services, carries out virtual machining and program code inspection, uses the processing status of the numerical control system for automatic identification, self-learning and adaptive functions, and self-optimization function, realizes the high-quality processing of workpieces, adopts industrial robots and numerical control machine tools for online batch detection, mainly used in high-efficiency and flexible processing of automobiles and CNC in batch manufacturing, and realizes the widespread application of machine tool parts.

In the face of the demand for high-quality and high-efficiency, integrated and intelligent production and manufacturing of complex parts with multiple degrees of freedom, future CNC systems will develop towards multi-degree-of-freedom composite processing. Once installed, it can complete turning, milling, and drilling on multiple surfaces. Multi-process composite processing. In addition, CNC systems must have more advanced trajectory planning and motor control strategies to achieve high-speed and high-precision machining.

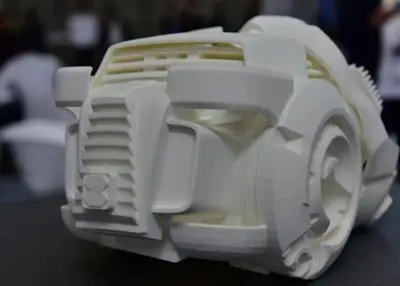

With the development trend of intelligent manufacturing, CNC systems must be equipped with highly intelligent human-machine interfaces to achieve planning functions and diagnostic and adaptive control strategies for machining processes. Future machining CNC technology will provide comprehensive self-monitoring and control throughout the entire machine tool manufacturing process. The CNC system can automatically plan the installation position, machining trajectory, and machine tool based on the 3D model of the part. Planning time is the shortest process step, and machine communication and collaboration within the factory may be achieved using Ethernet and Internet technologies. Communication between mechanical hands realizes automatic loading and unloading, achieving automatic, intelligent and rapid prototyping manufacturing of major complex parts.

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view Exploring the World of Medical Machined Parts: Precision in HealthcareNovember 10, 2023In the ever-evolving landscape of healthcare, the role of medical machined parts stands as a testament to precision engineering's indispensable contribution. As the CEO of Richconn, I am thrilled to guide you through an extensive exploration of these critical components.view

Exploring the World of Medical Machined Parts: Precision in HealthcareNovember 10, 2023In the ever-evolving landscape of healthcare, the role of medical machined parts stands as a testament to precision engineering's indispensable contribution. As the CEO of Richconn, I am thrilled to guide you through an extensive exploration of these critical components.view CNC Milling Definition Guide (Latest Insights for 2023)September 8, 2023CNC milling is a process of using a computer-controlled rotating cutting tool to remove material from a workpiece and create a custom-designed part or product. Milling is one of the most common types ...view

CNC Milling Definition Guide (Latest Insights for 2023)September 8, 2023CNC milling is a process of using a computer-controlled rotating cutting tool to remove material from a workpiece and create a custom-designed part or product. Milling is one of the most common types ...view The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view

The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view What Is Die Casting?March 7, 2024Do you know about die cast definition? This article introduces the definition, process, types, and everything you need to know about die cast.view

What Is Die Casting?March 7, 2024Do you know about die cast definition? This article introduces the definition, process, types, and everything you need to know about die cast.view What Tool is Best for Cutting Metal?October 8, 2023Cutting metal is a very common task in metalworking projects and different types of tools may be required for different metals and cutting requirements.view

What Tool is Best for Cutting Metal?October 8, 2023Cutting metal is a very common task in metalworking projects and different types of tools may be required for different metals and cutting requirements.view

EN

EN

ru

ru