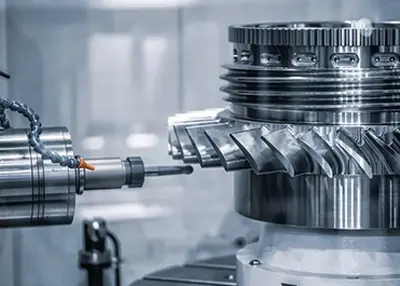

Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves, and other workpieces with rotating surfaces, and are the most widely used type of machine tool in mechanical manufacturing and repair factories.

The technology of a lathe operator is endless, and ordinary lathe operators do not require too high skills. It can be divided into 5 types of lathe operators, which are currently the most common in society. Turning machining is the most widely used in the machine manufacturing industry, with a large number of lathes, personnel, and a wide range of processing. There are also many tools and fixtures used, so safety issues in CNC turning processing become particularly important, with the focus on the following work.

The various steel parts processed on the lathe are tough, and the chips produced during turning are rich in plasticity and curl, and the edges are relatively sharp. When cutting steel parts at high speeds, red-hot, long chips are formed, which are extremely easy to injure people, and often entangle on workpieces, turning tools, and tool holders. Therefore, iron hooks should be used to clean or break them in time during work, and if necessary, the lathe should be stopped to clean them, but they must never be cleaned or pulled apart by hand. In order to prevent chip injury, measures such as chip breaking, controlling the direction of chip flow and adding various protective baffles are often taken. The measures for chip breaking are to grind chip-breaking grooves or steps on the turning tool; use appropriate chip-breaking devices and mechanical clamping tool holders.

In the process of turning, there are many accidents caused by improper clamping of the workpiece, which damage the machine tool, break or collide with the tools, and cause the workpiece to fall or fly out and injure people. Therefore, in order to ensure the safe production of CNC turning, special attention must be paid to the clamping of the workpiece. Suitable fixtures must be selected for parts of different sizes and shapes, and whether it is a three-jaw, four-jaw chuck or a special fixture, the connection with the spindle must be firm and reliable. The workpiece must be clamped tightly and properly, and a sleeve can be used to clamp large workpieces to ensure that the workpiece rotates at high speed and does not shift, fall off, or throw out when cutting forces are applied. If necessary, a center frame or top support can be used to enhance the clamping.

Before starting work, the CNC turning machine tool must be comprehensively checked and confirmed to be in good condition before use. The positioning of the workpiece and tool must be correct and firm. During the machining process, the machine must be stopped when changing tools, loading and unloading workpieces, and measuring workpieces. Do not touch the workpiece by hand or wipe it with a cloth while it is rotating. The cutting speed, feed rate, and depth of cut must be properly selected, and overloading processing is not allowed. Workpieces, fixtures, and other debris must not be placed on the bed, tool holder or bed surface. When using a file, move the turning tool to a safe position, with the right hand in front and the left hand behind, to prevent sleeves from getting caught. A special person should be responsible for using and maintaining the machine tool, and other personnel should not use it.

Exploring the Precision and Efficiency of CNC Tapping in MachiningNovember 22, 2023Precision in machining isn't just a goal; it's the essence that defines excellence. Within this realm, CNC tapping emerges as a beacon of accuracy, revolutionizing how threads are crafted and machines function. Let's delve deeper into this intricate world to uncover the precision and efficiency it offers.view

Exploring the Precision and Efficiency of CNC Tapping in MachiningNovember 22, 2023Precision in machining isn't just a goal; it's the essence that defines excellence. Within this realm, CNC tapping emerges as a beacon of accuracy, revolutionizing how threads are crafted and machines function. Let's delve deeper into this intricate world to uncover the precision and efficiency it offers.view Differences Between Chrome, Galvanized and Nickel PlatingOctober 20, 2023The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties.view

Differences Between Chrome, Galvanized and Nickel PlatingOctober 20, 2023The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties.view Titanium vs. Aluminum: Which is the Best Lightweight Metal?November 23, 2023Titanium and Aluminum are two excellent lightweight metals, and when it comes to machining, the choice of material is a crucial decision. Titanium and Aluminum are both common lightweight metal materials, and both have their own unique advantages in different situations.view

Titanium vs. Aluminum: Which is the Best Lightweight Metal?November 23, 2023Titanium and Aluminum are two excellent lightweight metals, and when it comes to machining, the choice of material is a crucial decision. Titanium and Aluminum are both common lightweight metal materials, and both have their own unique advantages in different situations.view Waterborne Aluminum Powder Coating on(Nylon+Fiberglass )Composite Materials: The Innovative Path to the FutureAugust 8, 2023Waterborne aluminum powder coating on nylon+fiberglass composite materials is an ingenious technology that combines nylon and fiberglass to give a unique metallic appearance. This innovative coating t...view

Waterborne Aluminum Powder Coating on(Nylon+Fiberglass )Composite Materials: The Innovative Path to the FutureAugust 8, 2023Waterborne aluminum powder coating on nylon+fiberglass composite materials is an ingenious technology that combines nylon and fiberglass to give a unique metallic appearance. This innovative coating t...view What Is a Shaft?October 30, 2023A shaft is basically a rotating part of any machine, having a circular cross-section, which is used to transmit power from one part to another or from a power generating machine to a power absorbing machine. To transmit power, one end of the shaft is connected to the power source and the other end is connected to the machine. Shafts can be solid or hollow as per requirement, hollow shafts help in reducing weight and provide advantages.view

What Is a Shaft?October 30, 2023A shaft is basically a rotating part of any machine, having a circular cross-section, which is used to transmit power from one part to another or from a power generating machine to a power absorbing machine. To transmit power, one end of the shaft is connected to the power source and the other end is connected to the machine. Shafts can be solid or hollow as per requirement, hollow shafts help in reducing weight and provide advantages.view Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view

Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view

EN

EN

ru

ru