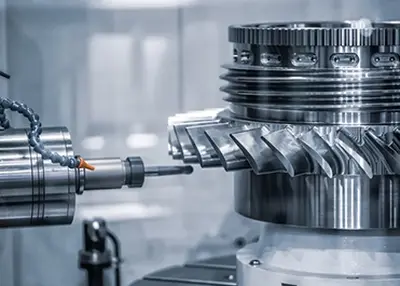

CNC machining can produce precision parts with strict tolerances and fine parts from various metal or plastic materials. Due to the influence of factors such as plastic deformation during chip separation, vibration of the process system, and friction between the tool and the processed surface, there are small tool marks on the part surface after machining. However, we can use various methods to improve the surface roughness, visual performance, and wear resistance of CNC machining parts. The most common metal CNC machining surface treatments listed below can help you choose the most suitable surface treatment for your application.

Complete options and the fastest turnover time. The parts have smaller visible tool marks and may have sharp edges or burrs, which can be removed as required. The standard machining surface roughness (Ra) is 3.2μm. Surface finish requirements can be increased to 1.6, 0.8, and 0.4μm.

Bead blasting adds a uniform matte or satin surface finish to machined OEM CNC machining parts, and removes tool marks. Mainly used for visual purposes.

Anodizing adds a corrosion-resistant ceramic layer to the surface of machined parts. It can be dyed in different colors, the most common being transparent, black, red, and gold. It is usually associated with aluminum and titanium. Type III adds a wear and corrosion-resistant ceramic layer to the surface of the part. It is thicker than type O and provides better protection. Only suitable for aluminum and titanium.

This is a process of spraying powder coating onto the components and then baking them in an oven. This creates a durable, wear-resistant, and corrosion-resistant layer that is more durable than standard coating methods. CNC powder coating has higher impact resistance than anodizing. Provides multiple colors. Can be applied to any metal.

This is a process of using electric current to reduce dissolved metal cations so that they form a thin, coherent metal coating on an electrode. Coatings help prevent corrosion and improve wear resistance, conductivity, reflectivity, and appearance.

CNC machining is a manufacturing process that improves efficiency by using higher levels of automation and allowing machines and their computers to control all aspects of the work. As you can imagine, CNC machining has many advantages in custom machining CNC parts.

Automation: CNC machining eliminates the need for the operator to do anything other than the work. CNC machines can stay on for hours or even days unattended if necessary, allowing operators to focus on other tasks.

Reproducibility: Once the design is sent to the computer, CNC machines can repeat the manufacturing process multiple times. In addition, you will always get high precision in the components.

Material range: CNC machining manufacturing is used to manufacture products made of various CNC machining materials. These include bronze, steel, aluminum, as well as gold and silver. Polymers such as ABS, polycarbonate, and PTFE can also be used with the machine.

Flexibility: CNC machining machines can be completely reprogrammed in a few hours to produce completely different products.

As a professional China CNC factory, Richconn provides quality OEM CNC machining solutions. If you have any other questions regarding CNC machining parts, feel free to contact us at any time.

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view Analysis of the Advantages and Characteristics of 4-axis Machining Center ProcessingOctober 24, 2022At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generall...view

Analysis of the Advantages and Characteristics of 4-axis Machining Center ProcessingOctober 24, 2022At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generall...view Aerospace CNC Machining: A Comprehensive GuideNovember 6, 2023Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.view

Aerospace CNC Machining: A Comprehensive GuideNovember 6, 2023Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.view How Many Fasteners Are Needed in the Construction Machinery Sector?October 27, 2023Fasteners as commonly used parts, you should not be unfamiliar, today Richconn from the classification of fasteners, the identification and inspection of threads, bolts, screws and studs of the material requirements, heat treatment requirements and mechanical performance requirements, the types of steel bolts and the construction of the four aspects of the introduction.view

How Many Fasteners Are Needed in the Construction Machinery Sector?October 27, 2023Fasteners as commonly used parts, you should not be unfamiliar, today Richconn from the classification of fasteners, the identification and inspection of threads, bolts, screws and studs of the material requirements, heat treatment requirements and mechanical performance requirements, the types of steel bolts and the construction of the four aspects of the introduction.view Safety Issues in CNC Turning TechnologyApril 25, 2023Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves,...view

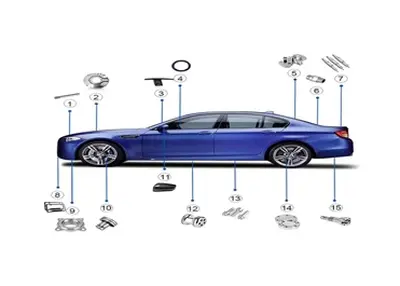

Safety Issues in CNC Turning TechnologyApril 25, 2023Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves,...view How CNC Automotive Parts Elevate Vehicle FunctionalityJanuary 5, 2024When it comes to the automotive industry, precision and performance are of utmost importance. Manufacturers are constantly striving to enhance the functionality of vehicles, which relies heavily on th...view

How CNC Automotive Parts Elevate Vehicle FunctionalityJanuary 5, 2024When it comes to the automotive industry, precision and performance are of utmost importance. Manufacturers are constantly striving to enhance the functionality of vehicles, which relies heavily on th...view

EN

EN

ru

ru