Understanding the intricacies of tapped holes is essential for various engineering and manufacturing applications. A tapped hole involves the creation of threads on its internal surface through the tapping process, allowing for the insertion of machine screws. This method is commonly employed in situations where nuts and bolts are not practical, offering a reliable means of securing threaded components. In the following discussion, we will talk about what is a tap hole and delve into the considerations and techniques involved in creating and utilizing tapped holes.

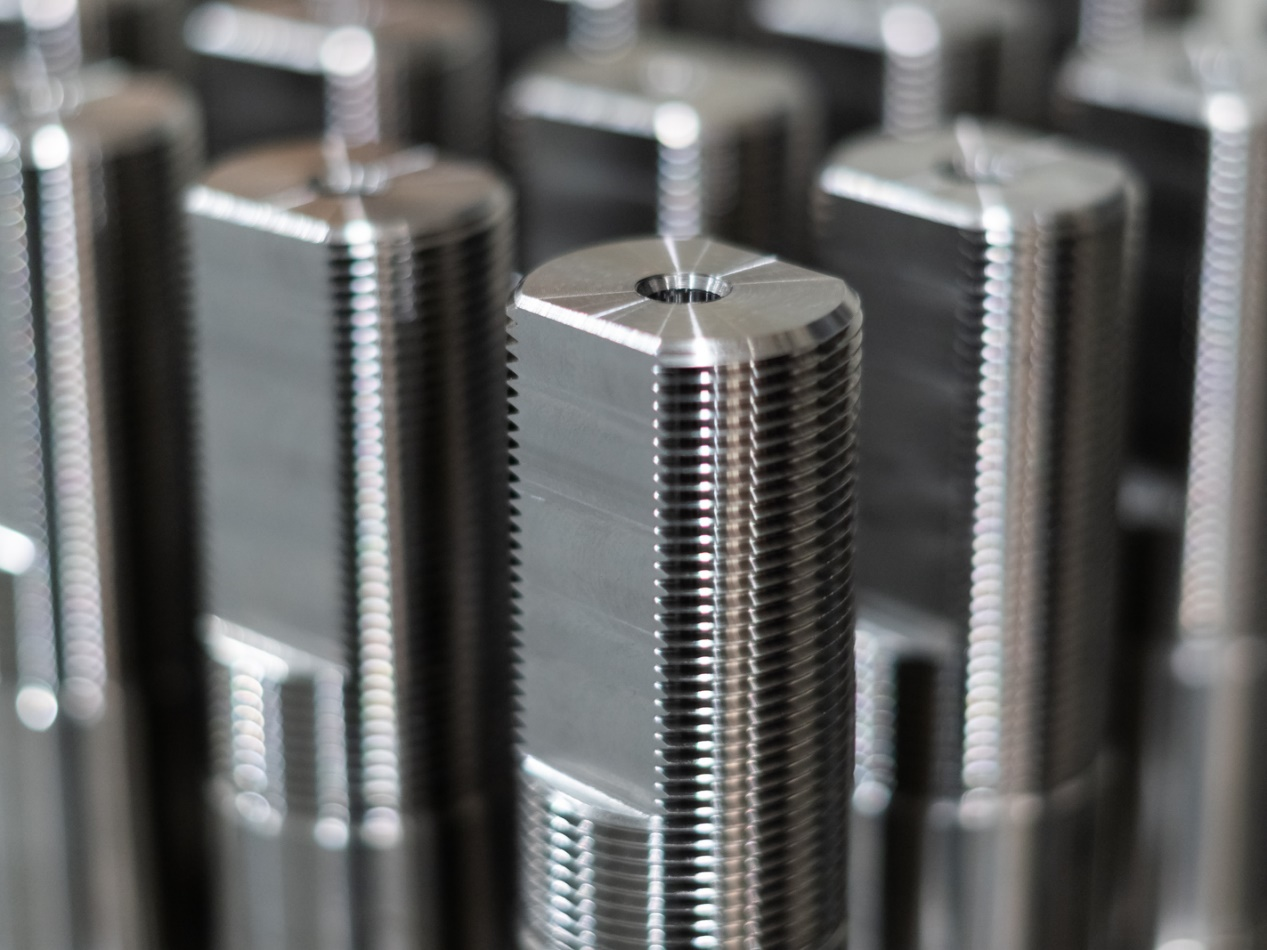

The tapped holes are the types of holes and drilled aperture with internal threads created using tapping tools. This method is crucial for providing a connection mechanism for parts using bolts or nuts. Not only does the threading prevent fasteners from becoming loose during use, but it also allows for the removal of the fastener when necessary.

Tapped holes are indispensable components of machined parts compared to thread holes, and they can be incorporated using a CNC machine. During the tapping process, threads are formed within the walls of the drilled hole. Machine screws are unable to generate their threads, making it essential to have a tapped hole to accommodate threaded elements in the CNC machining process.

Each feature of the hole for thread contributes effectively, with thread selection often based on their specific attributes. Let's explore the importance of threading a hole.

1. Secure Connection

By providing the ability to thread a bolt or screw into metals, tapped holes enable the reliable attachment of two parts, facilitating a secure and permanent connection.

2. Facilitated Transport

Incorporating tapped holes simplifies the assembly of small components and products, streamlining the shipping process and reducing labor costs.

3. Ease of Use

Tap hole creates a space for screw fasteners, allowing for the straightforward driving of screws or bolts into metal without the need for a pilot hole.

Creating tapped holes involves a systematic process of drilling the hole and using a tap to form the internal threads. This essential technique ensures secure and reliable fastening in various industries and applications.

Step 1: Drill the Hole

Using a twist drill, carefully create a hole of the desired diameter and depth. Ensure you choose the appropriate drill size for the required hole dimensions. To enhance the surface finish, consider using a cutting spray on the drill.

Step 2: Chamfer the Hole

To align the bolt and facilitate a smooth threading process, use a chamfer tool to create a slight beveled edge at the opening of the hole. This helps prevent burrs and prolongs the lifespan of the threading tool.

Step 3: Straighten the Hole

Use a drill and motor to ensure the hole is straight and the tap hole callout is right. Take note of the bolt size and corresponding hole size, ensuring the hole is slightly smaller than the bolt diameter. Be cautious with the hole depth, especially when not creating a through-hole.

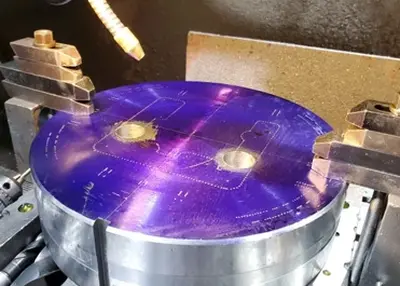

Step 4: Tap the Hole

Utilize a tap tool to create the internal threads in the drilled hole. Rotate the tap in a clockwise direction while

Taping a hole is influenced by factors such as the material properties, characteristics of the hole, and various other parameters outlined in detail below.

1. Material Hardness

Take into account the hardness of the material to be tapped. Harder materials may require specialized taps or cutting lubricants for clean and precise threading.

2. Standard Thread Size

Utilize standard thread sizes whenever possible. This ensures compatibility with readily available screws and bolts, simplifies replacement, and reduces the risk of compatibility issues.

3. Optimal Hole Depth

Determine the appropriate depth for the threaded hole based on the specific application requirements. Too shallow or too deep of a hole can compromise the integrity and function of the fastening.

4. Suitable Machinery

Choose the right machinery for the task, such as tapping machines or drill presses, to ensure accuracy and efficiency. Using the appropriate equipment can enhance to thread a hole with high quality.

5. Angled Surfaces

When dealing with angled or curved surfaces, ensure proper alignment and support during the tapping process. This helps maintain the integrity of the threads and prevents distortion.

6. Precision Positioning

Achieve precise hole positioning by using center punches or drill jigs to mark and guide the drilling process. Accurate alignment is crucial for creating high-quality threaded holes.

Understanding what is tapped hole important. However, it is often advantageous to entrust such tasks to professionals. CNC machining services prove to be a top choice, particularly for small and medium businesses, as they provide access to advanced technology and skilled operators without significant investments. When it comes to metal parts with tapped holes, precision, and execution is paramount. Our team possesses the ideal combination of tools and expertise to ensure flawless execution and timely delivery of threaded parts and other intricate assembly features. At Richconn, we strive to deliver the best results efficiently.

When it comes to tapping threaded holes, it is important to have a complete understanding of what does tap out means. Although this process may appear complex, it is advisable to seek guidance from our Richconn technique experts.

With years of machining experience, Richconn stands as a reliable option. Our team of skilled engineers specializes in various machining projects and prioritizes client satisfaction. Should you have any inquiries regarding tapping or machining threads, we are readily available to assist you. Please don't hesitate to reach out to us!

How Much Does Injection Molding Cost?August 9, 2023Injection molding is a widely used manufacturing process for the production of components and products. As with any manufacturing process, it is crucial to understand the cost factors involved in inje...view

How Much Does Injection Molding Cost?August 9, 2023Injection molding is a widely used manufacturing process for the production of components and products. As with any manufacturing process, it is crucial to understand the cost factors involved in inje...view The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view

The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view What Is Extruded Aluminum And How Does It Work?February 1, 2024Aluminum extrusion has been increasingly popular in making many types of products. What is aluminum extrusion? How does it work? Read this article about the extrusion process.view

What Is Extruded Aluminum And How Does It Work?February 1, 2024Aluminum extrusion has been increasingly popular in making many types of products. What is aluminum extrusion? How does it work? Read this article about the extrusion process.view Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view

Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view

The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view What Are The Characteristics and Features of CNC Machining?June 21, 2022Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining. The process rules of CNC machining and traditional machine tool machining are gen...view

What Are The Characteristics and Features of CNC Machining?June 21, 2022Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining. The process rules of CNC machining and traditional machine tool machining are gen...view

EN

EN

ru

ru