Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance. Depending on the amount and type of alloying elements, steel can be classified into two main categories: alloy steel and carbon steel. In this article, we will compare alloy steel vs carbon steel in terms of their composition, properties, and applications, and highlight their differences and advantages.

The main difference between alloy steel and carbon steel is the amount and type of alloying elements they contain. Alloy steel contains a higher percentage of alloying elements, such as manganese, nickel, chromium, molybdenum, vanadium, etc., than carbon steel. These elements can improve the strength, hardness, toughness, corrosion resistance, or wear resistance of alloy steel. Carbon steel contains a lower percentage of alloying elements, usually less than 2%, and mainly relies on carbon to increase its strength and hardness.

The table below shows the typical composition of some common alloy steels and carbon steels:

| Steel Grade | Carbon (%) | Manganese (%) | Silicon (%) | Chromium (%) | Molybdenum (%) | Nickel (%) | Vanadium (%) |

|---|---|---|---|---|---|---|---|

| 4140 | 0.38-0.43 | 0.75-1.00 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 | - | - |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 | - | - |

| 8620 | 0.18-0.23 | 0.70-0.90 | 0.15-0.35 | 0.40-0.60 | 0.15-0.25 | 0.40-0.70 | - |

| 4340 | 0.38-0.43 | 0.60-0.80 | 0.15-0.35 | 0.70-0.90 | 0.20-0.30 | 1.65-2.00 | - |

| A36 | 0.26 | 1.35 | 0.15-0.40 | - | - | - | - |

| 1018 | 0.14-0.20 | 0.60-0.90 | 0.15-0.35 | - | - | - | - |

The properties of alloy steel and carbon steel depend on their composition and heat treatment. Different alloying elements and heat treatment methods can produce different strength, hardness, toughness, and ductility of steel. The table below shows some typical mechanical properties of some common alloy steels and carbon steels in different heat treatment states:

| Steel Grade | Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| 4140 | Annealed | 655 | 415 | 25.7 | 197 |

| 4140 | Q&T | 1480 | 1275 | 17.7 | 444 |

| 4130 | Annealed | 560 | 360 | 28.2 | 156 |

| 4130 | Normalized | 670 | 460 | 22.4 | 187 |

| 4130 | Q&T | 860 | 700 | 18.1 | 321 |

| 8620 | Annealed | 530 | 385 | 22 | 149 |

| 8620 | Q&T | 980 | 785 | 10 | 331 |

| 4340 | Annealed | 745 | 470 | 22 | 217 |

| 4340 | Q&T | 1620 | 1480 | 12 | 477 |

| A36 | As-rolled | 400-550 | 250 | 20 | 119-159 |

| 1018 | As-rolled | 370-490 | 210 | 15 | 126 |

From the table, we can see that alloy steels generally have higher tensile strength, yield strength, and hardness than carbon steels, especially after quenching and tempering (Q&T). This indicates that alloy steels are more suitable for applications that require high load-bearing capacity and wear resistance. Carbon steels generally have lower tensile strength, yield strength, and hardness than alloy steels, but higher elongation. This indicates that carbon steels are more suitable for applications that require high formability and impact resistance.

The applications of alloy steel and carbon steel depend on their properties and prices. Different steels are suitable for different fields and industries. Here are some examples of the applications of alloy steel and carbon steel:

• Alloy steel: Due to its high strength, hardness, toughness, and corrosion resistance, alloy steel is mainly used for applications that require high performance and durability, such as aerospace, defense, automotive, mining, oil and gas, etc. Some examples of alloy steel products are gears, shafts, axles, bolts, pistons, cylinders, aircraft parts, tubing, chassis, roll cages, etc.

• Carbon steel: Due to its low cost, good weldability, and easy fabrication, carbon steel is mainly used for applications that require low to moderate strength and hardness, such as construction, machinery, transportation, etc. Some examples of carbon steel products are beams, plates, pipes, rails, wires, nails, screws, etc.

The alloy steel and carbon steel are two different types of steel, they have the following main differences and advantages:

Alloy steel contains more alloying elements than carbon steel, which can improve strength, hardness, toughness, corrosion resistance or wear resistance. Alloy steel has higher tensile strength, yield strength and hardness than carbon steel, especially after quenching and tempering. After fire, but the elongation is lower. Alloy steel is more suitable for applications requiring high load-bearing capacity and wear resistance.

Carbon steel contains a lower proportion of alloying elements than alloy steel, making it less expensive and easier to weld and fabricate. Carbon steel has lower tensile strength, yield strength and hardness than alloy steel, but has higher elongation. This makes it more suitable for applications requiring high formability and impact resistance.

Richconn has rich experience in CNC machining of Alloy Steel and Carbon Steel. It can select the appropriate Alloy Steel and Carbon Steel materials and processing technology according to your design requirements and application occasions to ensure the performance and quality of your products and provide you with precision CNC machining Serves.

In-Depth Overview: What Are Non-Ferrous Metals?August 7, 2023Metals may be found everywhere and are used for a variety of purposes. There are two different types of metals, ferrous and non-ferrous—based on how much iron they contain. Non-ferrous metals are a c...view

In-Depth Overview: What Are Non-Ferrous Metals?August 7, 2023Metals may be found everywhere and are used for a variety of purposes. There are two different types of metals, ferrous and non-ferrous—based on how much iron they contain. Non-ferrous metals are a c...view Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view

Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view

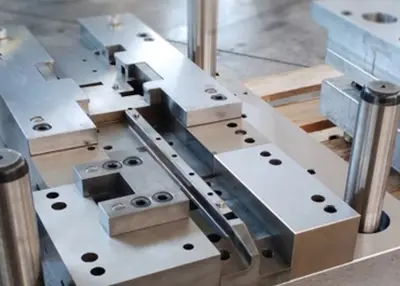

Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view Experience Sharing on Design and Manufacturing of Metal Stamping DiesJuly 21, 2023Here, we will share some specific design and manufacturing experiences to provide our understanding of dies accumulated over the years. Through this article, we hope to give you a better understanding...view

Experience Sharing on Design and Manufacturing of Metal Stamping DiesJuly 21, 2023Here, we will share some specific design and manufacturing experiences to provide our understanding of dies accumulated over the years. Through this article, we hope to give you a better understanding...view![Examining Alloy Definition and Alloying Examples [Basic Guide]](/uploads/image/20240226/14/basic-guide_400x400.webp) Examining Alloy Definition and Alloying Examples [Basic Guide]February 26, 2024Learn from alloy definitions and alloying examples, which can help you choose the best alloy for your project.view

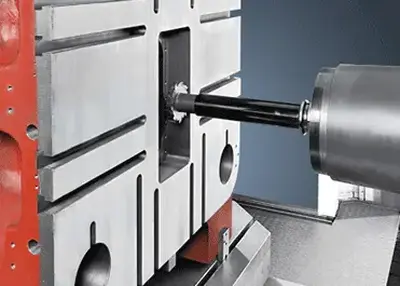

Examining Alloy Definition and Alloying Examples [Basic Guide]February 26, 2024Learn from alloy definitions and alloying examples, which can help you choose the best alloy for your project.view Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view

Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view

EN

EN

ru

ru