In the realm of metal fabrication, the choice between cast aluminum and machined aluminum holds the key to unlocking a world of possibilities. As a CNC machining service provider, we, at Richconn, understand the importance of making informed decisions in the manufacturing process. Let's embark on a journey to explore the nuances of these two techniques, dissecting their processes, comparing their performance, and uncovering their diverse applications.

In the realm of metal casting, the process of shaping aluminum is nothing short of an art. The journey begins with the meticulous preparation of the mold, a crucial step that sets the stage for the entire casting process. From sand casting to die casting, each method carries its nuances, influencing the final product's characteristics. The molten aluminum, heated to precision, flows into the mold, capturing every contour and detail. Cooling is a crucial phase, affecting the material's structural integrity and, consequently, its performance in real-world applications.

As we explore the advantages of cast aluminum, it's not merely about cost-effectiveness and efficiency. Cast aluminum's innate ability to assume complex shapes opens doors to design possibilities that machining might find challenging. The adaptability of cast aluminum in large-scale production scenarios stands testament to its prowess. Beyond the production line, the versatility of cast aluminum extends into applications demanding intricate geometries, where the casting process becomes a facilitator of creativity.

While cast aluminum brings a myriad of benefits, it's essential to navigate the limitations. Surface smoothness, a concern in certain applications, requires additional post-casting treatments for optimal results. Dimensional tolerances, although adequate for many applications, might pose challenges in precision-demanding industries. Acknowledging these limitations is pivotal for engineers and manufacturers to make informed decisions on the feasibility of cast aluminum for a given project.

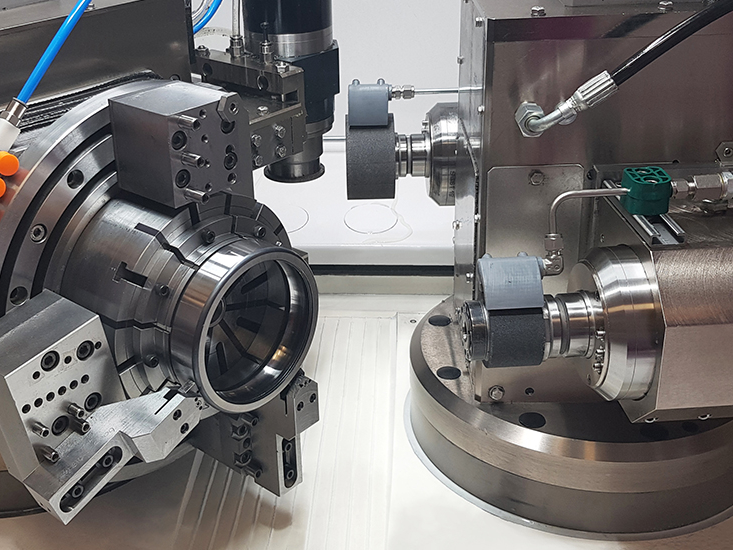

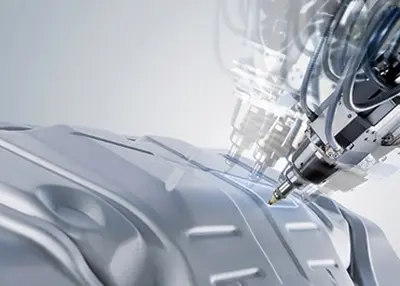

In the realm of machining aluminum, precision takes center stage. The process begins with carefully selected raw materials, often extruded or cast, to ensure a solid foundation for machining. Various cutting techniques, from milling intricate details to turning cylindrical forms, showcase the versatility of machining. The precision achievable through these methods is unparalleled, making machined aluminum the go-to choice for components demanding exacting specifications.

The advantages of machined aluminum extend far beyond its precise nature. In sectors where tight tolerances and impeccable surface finishes are paramount, machining emerges as the undisputed champion. The ability to achieve near-perfect symmetry and accuracy makes machined aluminum the preferred material for critical components in aerospace, medical devices, and electronic systems. Its versatility spans from prototyping to full-scale production, offering a level of customization that meets the most stringent requirements.

While machining aluminum elevates precision, it comes with its set of considerations. The intricacy and precision achieved contribute to higher costs, both in terms of equipment and labor. Scaling up production might encounter challenges, especially with larger components. Manufacturers must weigh the benefits against the costs, ensuring that the exceptional precision of machined aluminum aligns with the project's budgetary constraints.

As we pit cast against machined aluminum in the arena of physical performance, the clash of attributes becomes evident. Cast aluminum, with its slightly lower density, often proves advantageous in applications where weight is a critical factor. However, machined aluminum, boasting higher strength and hardness, asserts dominance in scenarios demanding structural integrity and durability. Understanding these nuanced differences empowers engineers to select the optimal material based on the specific requirements of their projects.

In the quest for corrosion resistance, both cast and machined aluminum exhibit commendable performance, albeit with subtle distinctions. Cast aluminum, being more porous, might require additional protective coatings in corrosive environments. On the other hand, the smoother surface finishing of machined aluminum provides a natural barrier against corrosion.

The battleground shifts to temperature stability as we assess how cast and machined aluminum fare under extreme thermal conditions. Cast aluminum, with its generally lower melting point, may encounter limitations in high-temperature environments. In contrast, machined aluminum's robustness and resistance to thermal deformation position it favorably for applications demanding resilience in varying temperature ranges. Navigating this face-off ensures that the chosen material aligns seamlessly with the project's thermal requirements.

The dominance of cast aluminum in various industries unfolds as we explore its versatile applications. In the automotive sector, where complex designs meet durability requirements, cast aluminum components find their niche. The construction industry benefits from cast aluminum's cost-effectiveness and ability to assume diverse shapes, contributing to structural integrity. In aerospace, the lightweight nature of cast aluminum becomes a pivotal factor, enhancing fuel efficiency without compromising strength.

Machined aluminum carves out its niche in sectors demanding the utmost precision. In the realm of electronics, where miniaturization and intricate detailing are paramount, machined aluminum components find their home. Aerospace applications leverage the precision of machined aluminum for critical parts requiring flawless performance. The medical equipment industry relies on machined aluminum's biocompatibility and precision for instruments and implants.

Deciphering the economics of cast and machined aluminum involves a comprehensive analysis. Cast aluminum's cost-effectiveness stems from the efficiency of the casting process, but considerations like post-processing treatments add nuances. On the other hand, the precision and customization offered by machined aluminum come with a higher price tag. Availability, influenced by market demand and production scalability, further shapes the economic landscape for both variants.

In the intricate world of aluminum fabrication, the choice between cast and machined aluminum holds profound implications for project success. As we navigate the complexities, it's imperative to recognize that each method brings unique advantages and considerations to the table. At Richconn, we stand at the intersection of craftsmanship and innovation, offering tailored CNC machining services to meet the diverse needs of our clients.

The strategic decision between cast and machined aluminum hinges on a thorough understanding of project requirements. While cast aluminum excels in scenarios demanding cost-effectiveness and versatility in design, machined aluminum emerges as the frontrunner in applications requiring unparalleled precision. At Richconn, our expertise lies in guiding clients through this decision-making process, ensuring that the chosen material aligns seamlessly with their project objectives.

Collaboration is the cornerstone of success in aluminum fabrication. At Richconn, our commitment extends beyond providing CNC machining services. We collaborate closely with clients, understanding the intricacies of their projects, and offering insights that optimize the chosen manufacturing method. This collaborative approach ensures that the final product not only meets but exceeds expectations, embodying the perfect synergy of design and functionality.

In the pursuit of precision, our CNC machining capabilities stand as a testament to Richconn's commitment to excellence. Our state-of-the-art machining centers, operated by skilled technicians, enable the production of components with meticulous accuracy. Whether it's creating intricate prototypes or fulfilling large-scale production requirements, our advanced CNC machining capabilities empower clients to push the boundaries of what's achievable in aluminum fabrication.

In the realm of cast aluminum vs. machined aluminum, the journey is not just about choosing a material; it's about making an informed decision that aligns with your project's vision. Richconn, with its blend of expertise, innovation, and collaborative spirit, stands as your partner in this journey. As you embark on the path of aluminum fabrication, let Richconn be the catalyst that transforms your concepts into tangible excellence. Empower your aluminum journey with Richconn – where precision meets innovation.

What Does Color Flaw Detection Mean?October 19, 2023Color flaw detection is a method of non-destructive testing, it is a surface inspection method, mainly used to detect such as the naked eye can not identify the cracks and other surface damage, such as the detection of stainless steel material near the surface defects (cracks), porosity, porosity, delamination, unwelded and unfused and other defects (also known as PT detection).view

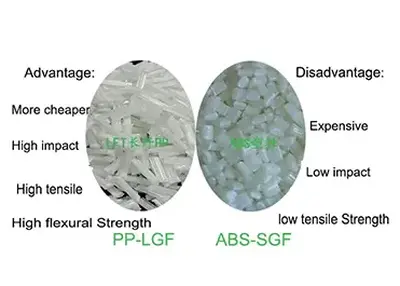

What Does Color Flaw Detection Mean?October 19, 2023Color flaw detection is a method of non-destructive testing, it is a surface inspection method, mainly used to detect such as the naked eye can not identify the cracks and other surface damage, such as the detection of stainless steel material near the surface defects (cracks), porosity, porosity, delamination, unwelded and unfused and other defects (also known as PT detection).view ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view

ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view How to choose the right material for cnc cnc machining parts?November 1, 2023In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.view

How to choose the right material for cnc cnc machining parts?November 1, 2023In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.view What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view

What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view

The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view

Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view

EN

EN

ru

ru