Metals may be found everywhere and are used for a variety of purposes. There are two different types of metals, ferrous and non-ferrous—based on how much iron they contain. Non-ferrous metals are a crucial part of our everyday lives, yet many people are unaware of their significance. Here, we will give you more details so you can know more about nonferrous metals.

Non-Ferrous metals refer to metals without iron or ferrous components. Generally, non-ferrous metals are more expensive than ferrous metals. Despite the cost, owing to their amazing properties, like rust and corrosion resistance, ease of fabrication, and non-magnetic abilities, manufacturers still choose them.

Non-ferrous metals also take pride in their recyclability. It's much easier to recycle non-ferrous metals than mine. The processes involved in recycling, such as re-smelting and re-casting, are far more sustainable compared to the environmentally damaging methods used in mining.

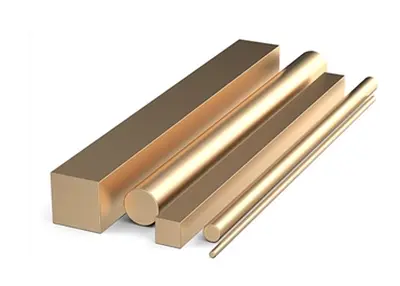

Common materials of non-ferrous metals include aluminium, nickel, tin, copper, lead, titanium and zinc, as well as copper alloys like brass and bronze. Some examples of rare or precious nonferrous metals are gold, silver, and platinum.

Nowadays, non-ferrous metals can be easily seen in commercial, industrial, and residential sections. No matter for commercial, industrial, or residential needs, a careful material selection process based on their mechanical properties is needed. The main properties often include lightweight, conductivity, corrosion resistance, non-magnetic properties, etc. Let's examine these properties!

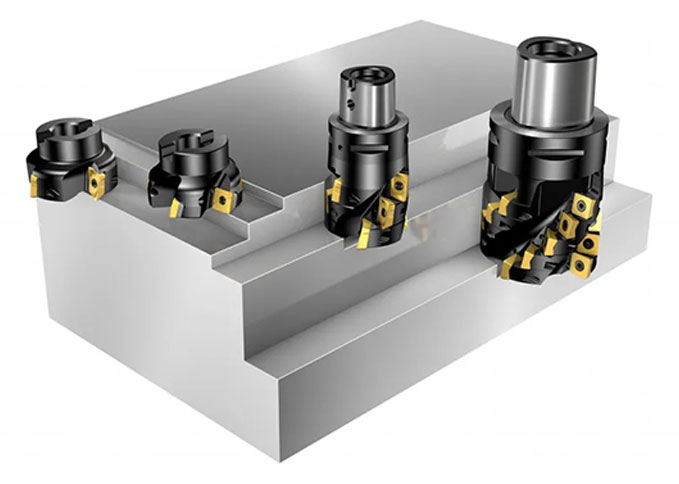

Non-ferrous metals, such as aluminium, copper, and brass, can be easily fabricated through processes like OEM CNC machining, casting, and welding.

Non-ferrous metals are generally more resistant to corrosion than ferrous metals. This is because they do not contain iron, which is susceptible to oxidation and rusting.

Non-ferrous metals, especially copper and aluminum, have excellent thermal and electrical conductivity. This makes them ideal for applications such as electrical wiring and heat transfer.

Non-ferrous metals are typically lighter in weight compared to ferrous metals. This makes them suitable for use in industries where weight reduction is important, such as the aerospace industry.

Unlike ferrous metals, non-ferrous metals are generally non-magnetic. This property makes them useful in applications where magnetic interference needs to be minimized, such as in electrical and electronic devices.

Some non-ferrous metals, like copper and brass, have distinctive colors. This makes them aesthetically pleasing and often utilized in decorative applications.

Today, non-ferrous metals, which do not contain iron, have become more and more popular due to their versatility and durability. They are widely used in construction, transportation, electronics, aerospace industries, and more. Here are the main examples and applications of non-ferrous metals.

One of the most well-known non-ferrous metals is aluminium. It is corrosion-resistant, lightweight, and has outstanding conductivity. These qualities make it an ideal choice for applications such as aircraft construction and electrical wiring. Although it is a rather pricey commodity, aluminium serves as the foundation metal for numerous alloys.

Despite having excellent ductility and malleability, corrosion resistance, and strong heat and electricity conductivity (albeit not as well as copper), aluminium sometimes requires annealing because, after cold working, it becomes hard.

Numerous industries utilize copper and its alloys, including bronze (copper and tin) and brass (copper and zinc). This is because of its excellent electrical conductivity, corrosion resistance and durability, and high thermal and electrical conductivity. It is soft and ductile when it is not alloyed.

These properties have allowed copper and its alloys to be used in electrical wiring. Copper is an excellent conductor of electricity, making it ideal for transmitting electrical current with minimal resistance. It is also commonly used in other electrical components and devices. However, copper can tarnish over time, especially when exposed to air and moisture.

Zinc is a chemical element with the symbol Zn. It is a bluish-white metal that is commonly found in the Earth's crust. Zinc can be alloyed with various metals to create alloys with a wide range of properties, making it highly versatile in different industries.

Zinc is often used as an alloying agent to create different types of alloys. For example, brass is made by combining zinc with copper, while nickel silver contains zinc, copper, and nickel. These alloys possess unique properties that make them suitable for various applications, including construction, electrical equipment, and musical instruments.

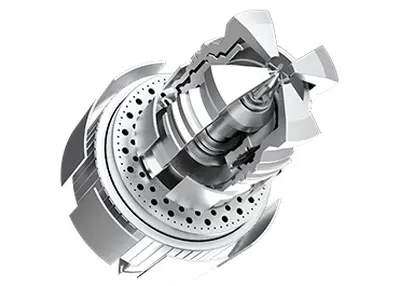

Titanium stands out for its exceptional strength-to-weight ratio and resistance to extreme temperatures. This makes it indispensable in the aerospace industry for constructing aircraft frames and engine components. It is also widely used in the agricultural, medical, sporting, military, and automotive industries. But titanium has limited availability due to its scarcity. This can lead to higher lead times and difficulties in sourcing these materials.

Non-ferrous metal casting can be made through sand casting, metal mold casting, and investment casting. The metal mold casting process mainly includes two types, low-pressure permanent mold process and high-pressure die-casting process (HDC). Non-ferrous metals are perfect for structural applications due to their low density, high strength-to-density ratio, high conductivity, resistance to rust and corrosion, and non-magnetic ability.

Non-ferrous metals are often refined by manufacturers using electrolysis. Before pouring the cast, manufacturers mix the metal into the iron used in the casting process. This aims to get a special cast iron or alloy steel with enhanced properties.

Richconn, a leading China CNC company, can help you manufacture metal parts like non-ferrous metals and prototypes beyond your expectation at a lower price.

Richconn is known for its efficient production and fast handling processes. They prioritize meeting customer timelines and ensuring short lead times for orders.

Richconn has extensive experience in CNC metal machining including manufacturing non-ferrous metals. Equipped with cutting-edge technologies and advanced machinery, the manufacturing process offered by Richconn can be more efficient and the precision of parts can be increased.

Richconn offers extensive and strong manufacturing capabilities for every customer. With comprehensive services from CNC machining, sheet metal fabrication, CNC surface finish to 3D printing services, and more. Our solution satisfies a wide spectrum of industries and applications.

Non-ferrous metals have been utilized by humans for a variety of purposes for thousands of years. Nowadays, they still have a wide range of uses, from decoration to electronics, aerospace, and other fields. To maximize their benefits, it is important to choose the best manufacturing service provider. Looking for a trusted and reliable one to help you achieve your goals? Richconn must be the best pick for you! To get a quote, all you need to do is upload your design file and fill in the basic information here. So what are you waiting for? Contact Richconn NOW!

What is face milling?November 22, 2023Face milling is a metalworking process that is widely used in manufacturing and machining. It is a process in which the surface of a workpiece is cut by a milling cutter on a milling machine to obtain the desired shape, size and surface quality. Face milling can be used to process a variety of metallic and non-metallic materials, including steel, aluminum, copper, plastics and so on.view

What is face milling?November 22, 2023Face milling is a metalworking process that is widely used in manufacturing and machining. It is a process in which the surface of a workpiece is cut by a milling cutter on a milling machine to obtain the desired shape, size and surface quality. Face milling can be used to process a variety of metallic and non-metallic materials, including steel, aluminum, copper, plastics and so on.view What Kind of Common CNC Metal Machining Technology Do You Know?August 10, 20221. CNC metal machining technology: selective laser meltingIn a tank filled with metal powder, a computer-controlled high-power carbon dioxide laser selectively sweeps the surface of the metal powder. ...view

What Kind of Common CNC Metal Machining Technology Do You Know?August 10, 20221. CNC metal machining technology: selective laser meltingIn a tank filled with metal powder, a computer-controlled high-power carbon dioxide laser selectively sweeps the surface of the metal powder. ...view Unleashing Precision: Richconn's CNC Machined Steel ExcellenceNovember 10, 2023Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining.view

Unleashing Precision: Richconn's CNC Machined Steel ExcellenceNovember 10, 2023Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining.view What Are Machining Operations?November 3, 2023Machining operations are at the core of modern manufacturing. These processes are the backbone of industries like aerospace, automotive, and electronics, allowing for precise shaping and finishing of materials.view

What Are Machining Operations?November 3, 2023Machining operations are at the core of modern manufacturing. These processes are the backbone of industries like aerospace, automotive, and electronics, allowing for precise shaping and finishing of materials.view Applications of CNC Machining in Automotive IndustryJune 14, 2024As we know, CNC machining is widely used in automotive manufacturing. What is the specific application of CNC machining in the field of automotive manufacturing? Here come the answers!view

Applications of CNC Machining in Automotive IndustryJune 14, 2024As we know, CNC machining is widely used in automotive manufacturing. What is the specific application of CNC machining in the field of automotive manufacturing? Here come the answers!view Chip Types Of Automatic Gear Production Line And Application Scope Of Chip Treatment SystemApril 12, 2022This paper studies the characteristics of different kinds of chips produced in the process of gear machining and gives the corresponding treatment scheme, which provides technical support for the auto...view

Chip Types Of Automatic Gear Production Line And Application Scope Of Chip Treatment SystemApril 12, 2022This paper studies the characteristics of different kinds of chips produced in the process of gear machining and gives the corresponding treatment scheme, which provides technical support for the auto...view

EN

EN

ru

ru