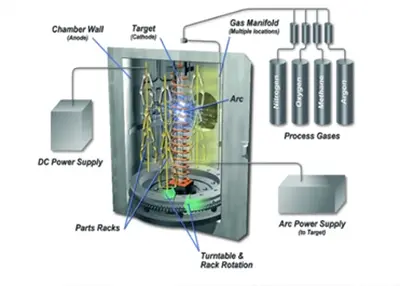

The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties. In this article, we will discuss in-depth the three common types of electroplating processes: chrome plating, galvanizing, and nickel plating to help readers better understand the differences between them and their respective areas of application.

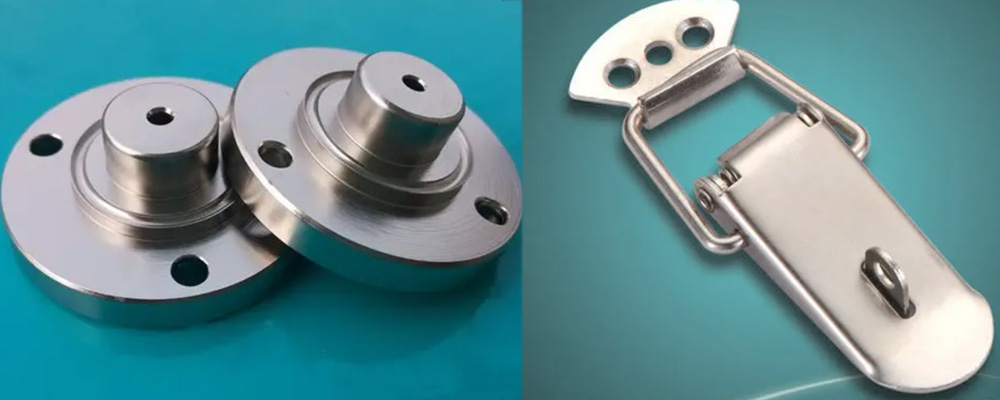

Chromium plating is a process in which a layer of chromium is applied to a metallic or non-metallic surface. Chrome is a silvery-white metal, usually with a blue tint. Chrome plating can be categorized into two types: decorative and functional.

Decorative chrome plating is used to enhance the splendor of an exterior, reduce rust resistance, improve wear resistance, etc. This type of chrome plating is usually used on home appliances, hardware, faucets and other products to add a decorative element and make them more attractive.

Functional chrome plating, on the other hand, is mainly used to improve the hardness and wear resistance of parts. This type of chrome plating is widely used on industrial and mechanical parts that need to withstand high levels of wear and tear. For example, chrome plating on automotive engine parts and machine tools significantly increases their durability.

Zinc plating is a surface treatment that provides aesthetic appeal and rust resistance by applying a layer of zinc to the surface of a metal, alloy, or other material. Zinc plating is usually shiny white in color and provides excellent corrosion protection. This treatment is widely used in a variety of fields, including construction, the power industry, and industrial equipment manufacturing.

A major application of galvanizing is in construction materials. Galvanizing steel prevents it from rusting, improves its service life, and makes it more durable in outdoor environments. In addition, the wire and cable industry uses galvanization to improve the rust resistance of their products and ensure their reliability.

Nickel plating is a process in which a layer of nickel is applied to a metallic or non-metallic surface by electrolysis or other chemical methods. Nickel plating usually appears as a bright white or yellow color and is very attractive, so it is primarily used for decorative applications.

Despite its relative complexity, nickel plating is still widely used in a number of products. For example, energy saving lamp holders are often nickel plated to provide a bright appearance, while coins are often coated with a layer of nickel to improve their durability and aesthetics.

The plating process is an indispensable tool in industrial design, allowing for a wide range of functionality and aesthetics by forming a metallic or alloy layer on the surface of an object. Chrome plating, galvanizing and nickel plating are three of the common types, and they play a key role in different applications. Choosing the right plating method depends on the specific needs, whether it is for aesthetics or to improve the performance of the material, you can find the right choice among these processes.

We hope this article has been helpful in understanding and differentiating between plating processes. Electroplating is a complex and diverse field that will continue to play a key role in various industrial sectors as technology continues to advance.

For those seeking plating services, it is worth noting that one precision machine shop, Richconn, founded in 2008, offers a full range of services. Not only do we offer CNC machining services and sheet metal services, but we also offer plating services for a variety of industrial design and production needs. Whether you need chrome plating, galvanizing, or nickel plating, Richconn can provide you with a professional solution to ensure that your product meets the expected quality and performance standards. If you have any questions about our services or need further information, please feel free to contact them for more information.

Waterjet Cutting: Methods, Applications, and BenefitsJune 21, 2024Waterjet cutting is a special cutting technique that is progressively drawing interest from an increasing number of industries. The technical underpinnings, benefits, and areas of application of waterjet cutting will be thoroughly covered in this article.view

Waterjet Cutting: Methods, Applications, and BenefitsJune 21, 2024Waterjet cutting is a special cutting technique that is progressively drawing interest from an increasing number of industries. The technical underpinnings, benefits, and areas of application of waterjet cutting will be thoroughly covered in this article.view Switching From Metal to PlasticOctober 18, 2023The manufacturing sector is constantly evolving as new trends and processes emerge. Among the most interesting trends is the relatively new idea of designers to replace metal parts with plastic injection molding.view

Switching From Metal to PlasticOctober 18, 2023The manufacturing sector is constantly evolving as new trends and processes emerge. Among the most interesting trends is the relatively new idea of designers to replace metal parts with plastic injection molding.view Alloy Steel vs Carbon Steel: Which Is Better?September 5, 2023Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific ...view

Alloy Steel vs Carbon Steel: Which Is Better?September 5, 2023Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific ...view CNC Machining Aerospace Parts Need to Know 8 Points of MattersOctober 25, 2023CNC machining is one of the most widely used manufacturing methods in the aerospace industry. While you probably know at least a little about it, here are 8 things you need to know when CNC machining aerospace parts.view

CNC Machining Aerospace Parts Need to Know 8 Points of MattersOctober 25, 2023CNC machining is one of the most widely used manufacturing methods in the aerospace industry. While you probably know at least a little about it, here are 8 things you need to know when CNC machining aerospace parts.view The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view

The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view

Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view

EN

EN

ru

ru