In a world where Precision Machining innovation, Richconn stands as a pioneer in CNC machining technology, redefining the landscape of iPhone protection. Dive into the intricacies of CNC machining for iPhone cases and discover a realm where design meets durability, guided by a commitment to excellence.

In the realm of precision engineering, CNC machining stands as the cornerstone of innovation. At Richconn, our commitment to excellence is intertwined with our mastery of CNC machining technology. Let's delve deeper into the intricacies of this cutting-edge process.

CNC machining, or Computer Numerical Control machining, is a sophisticated manufacturing process that utilizes computerized controls to operate and manipulate machining tools. The precision achieved through CNC machining is unparalleled, making it the preferred choice for crafting intricate components with high accuracy.

In the context of iPhone case manufacturing, CNC machining takes center stage due to its ability to transform digital designs into physical products with remarkable precision. The process involves feeding digital design data into a computer, which then controls the movement of the machining tools, ensuring every cut and operation is executed with meticulous accuracy.

Beyond the world of iPhone cases, CNC machining finds extensive application across various industries. From aerospace components to medical devices, the versatility of CNC machining allows for the production of intricate parts that meet stringent quality standards.

In the iPhone case manufacturing process, CNC machining plays a pivotal role in shaping the final product. The technology enables the creation of precise molds and patterns, ensuring a seamless fit for the iPhone while maintaining a sleek and stylish design.

The adoption of CNC machining in crafting iPhone cases brings forth a multitude of advantages. Firstly, the level of precision achievable ensures that each case is tailored to the exact specifications of the digital design. This not only enhances the aesthetics but also contributes to the functional aspects of the case.

Moreover, CNC machining allows for rapid prototyping, facilitating the quick testing and refinement of designs. This agility in the manufacturing process enables Richconn to stay at the forefront of design trends, offering customers the latest and most innovative iPhone cases.

Ensuring the highest quality in CNC machined iPhone cases is a top priority at Richconn. Rigorous quality control measures are implemented at every stage of the manufacturing process. From material inspection to the final inspection of the finished product, our commitment to excellence is unwavering.

To provide a clear overview of our quality control process, let's explore a table detailing the key inspection points and criteria:

| Inspection Stage | Criteria |

|---|---|

| Material Inspection | Check for material integrity and compliance |

| Machining Process | Validate precision against design parameters |

| Surface Finish Control | Ensure a smooth and flawless finish |

| Final Product Inspection | Confirm overall quality and adherence to specifications |

This meticulous approach to quality control guarantees that each CNC machined iPhone case leaving our facility meets the highest standards, providing customers with a product they can trust.

In the dynamic world of iPhone accessories, design flexibility and durability are paramount. Richconn's utilization of CNC machining technology not only ensures precision but also significantly impacts the design flexibility and durability of our iPhone cases.

One of the defining features of CNC machining is its ability to translate intricate digital designs into tangible products with unmatched accuracy. This capability empowers our designers to push the boundaries of creativity, offering customers a diverse range of iPhone cases that cater to various tastes and preferences.

From intricately engraved patterns to personalized designs, CNC machining allows for the realization of virtually any design concept. The flexibility to experiment with shapes, textures, and details ensures that each iPhone case produced by Richconn is a unique work of art.

To illustrate the design possibilities, consider the following table showcasing different design elements achievable through CNC machining:

| Design Element | Description |

|---|---|

| Engraved Patterns | Intricate and precise patterns for a premium look |

| Customized Logos | Brand your iPhone case with a personalized touch |

| Texture Variations | Explore different textures for a tactile experience |

| Unique Shapes | Design cases with unconventional and eye-catching shapes |

By harnessing the capabilities of CNC machining, Richconn brings forth a collection of iPhone cases that not only protect your device but also serve as a reflection of your personal style.

In addition to design flexibility, CNC machining contributes significantly to the durability of our iPhone cases. The precision with which each case is crafted ensures that it seamlessly fits the iPhone, providing optimal protection without compromising on aesthetics.

The structural stability achieved through CNC machining results in iPhone cases that can withstand daily wear and tear. Whether it's accidental drops, impacts, or exposure to various environmental factors, our cases are engineered to endure, ensuring the longevity of both the case and the device it protects.

To further illustrate the durability of our CNC machined iPhone cases, consider the following table outlining key durability features:

| Durability Feature | Description |

|---|---|

| Impact Resistance | Absorbs and disperses impact energy for enhanced protection |

| Scratch Resistance | Surface treated to resist scratches and maintain a pristine appearance |

| Environmental Resilience | Withstands exposure to elements such as water, dust, and UV radiation |

Richconn's commitment to providing durable iPhone cases goes beyond aesthetics, aiming to safeguard your device in every circumstance.

To bring these concepts to life, let's explore a few real-world scenarios where design flexibility and durability intersect in our CNC machined iPhone cases:

Professional Elegance: Our engraved pattern designs cater to professionals who seek an iPhone case that not only protects their device but also complements their sophisticated style in business settings.

Outdoor Adventure: For those who lead an active lifestyle, our durable cases with impact resistance and environmental resilience are the ideal companions, ensuring their iPhones remain intact during outdoor adventures.

Customized Branding: Businesses looking to elevate their brand image can opt for customized logos on iPhone cases, turning them into promotional tools that showcase their unique identity.

In the meticulous process of crafting CNC machined iPhone cases, material selection plays a pivotal role in ensuring not just aesthetics, but also the overall quality and performance of the final product. At Richconn, we prioritize materials that not only meet industry standards but exceed them, providing customers with a product they can trust.

The materials used in CNC machining for iPhone cases encompass a range of options, each with its unique characteristics. From metals to polymers, the choice of material influences not only the physical appearance of the case but also factors such as durability, weight, and texture.

Aluminum Alloy: Renowned for its lightweight yet robust nature, aluminum alloy is a popular choice for CNC machined iPhone cases. Its malleability allows for intricate designs, while its durability ensures optimal protection for the device.

Polycarbonate: Recognized for its impact resistance, polycarbonate is often used in the manufacturing of iPhone cases. Its ability to withstand shocks and impacts makes it an ideal material for customers seeking rugged protection without compromising on style.

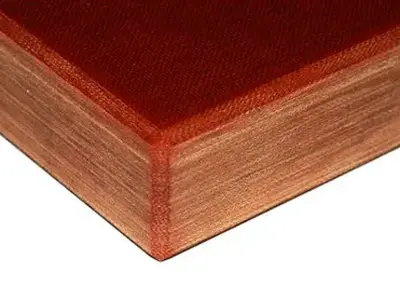

Premium Wood Veneers: For those with a penchant for natural aesthetics, Richconn offers CNC machined iPhone cases with premium wood veneers. These cases provide a unique blend of sophistication and environmental consciousness.

To assist customers in making informed choices, let's break down the key characteristics of the materials commonly used in CNC machined iPhone cases:

| Material | Characteristics |

|---|---|

| Aluminum Alloy | Lightweight, durable, and allows for intricate designs |

| Polycarbonate | Impact-resistant, provides rugged protection |

| Premium Wood Veneers | Offers a natural and sophisticated aesthetic |

By understanding these characteristics, customers can align their preferences with the material that best suits their lifestyle and protection needs.

Ensuring the quality of materials is a critical aspect of Richconn's commitment to excellence. Let's explore the stringent quality assurance measures implemented:

Material Sourcing: Richconn collaborates with trusted suppliers to source high-quality materials. Regular audits and inspections are conducted to ensure consistency and adherence to specifications.

Material Testing: Before entering the production phase, materials undergo rigorous testing. This includes assessments for durability, resistance to environmental factors, and compliance with industry standards.

Supplier Certifications: Suppliers are required to provide certifications that validate the quality and authenticity of the materials. This ensures transparency and builds confidence in the materials used for CNC machined iPhone cases.

Richconn takes pride in not just providing CNC machined iPhone cases but in offering a comprehensive service that encompasses quality, customization, and customer satisfaction. This section sheds light on the background and strength of Richconn, offering a detailed purchasing guide for those looking to experience the epitome of precision and design.

Established as pioneers in CNC machining services, Richconn brings decades of expertise to the table. Our journey has been marked by a relentless pursuit of excellence, blending traditional craftsmanship with cutting-edge technology. Let's explore what sets Richconn apart:

In-House Expertise: Richconn boasts an in-house team of skilled technicians and designers. This in-house expertise allows for seamless collaboration, ensuring that design concepts translate flawlessly into CNC machined iPhone cases.

State-of-the-Art Facilities: Our manufacturing facilities are equipped with state-of-the-art CNC machining equipment. This technology, coupled with stringent quality control measures, guarantees the production of iPhone cases that meet the highest standards.

Commitment to Innovation: Richconn continuously invests in research and development, staying ahead of technological advancements. This commitment to innovation ensures that customers receive iPhone cases that reflect the latest in design and functionality.

The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view

The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view

Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view

Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view Bakelite: The First Synthetic Plastic and Its ApplicationsDecember 7, 2023Bakelite is a synthetic material that was invented in the early 20th century by Leo Baekeland, a Belgian-American chemist. Bakelite is considered to be the first true plastic, as it was the first material that was not derived from natural sources, such as cellulose, rubber, or horn.view

Bakelite: The First Synthetic Plastic and Its ApplicationsDecember 7, 2023Bakelite is a synthetic material that was invented in the early 20th century by Leo Baekeland, a Belgian-American chemist. Bakelite is considered to be the first true plastic, as it was the first material that was not derived from natural sources, such as cellulose, rubber, or horn.view What Is CNC Process? CNC Machining Process Design PrinciplesMarch 6, 20231, the maximum concentration of CNC machining process, a positioning principleGenerally in the CNC machine tools, especially in the machining center on the processing parts, the process can be maximal...view

What Is CNC Process? CNC Machining Process Design PrinciplesMarch 6, 20231, the maximum concentration of CNC machining process, a positioning principleGenerally in the CNC machine tools, especially in the machining center on the processing parts, the process can be maximal...view Roller Design and Manufacturing Analysis - Everything You Want to Know is Here: Revealing the Complexities of Roller Design and ManufacturingJuly 17, 2023IntroductionWelcome to this comprehensive guide on roller design and manufacturing analysis - everything you want to know is here. Rollers play a key role across industries, providing support, guidanc...view

Roller Design and Manufacturing Analysis - Everything You Want to Know is Here: Revealing the Complexities of Roller Design and ManufacturingJuly 17, 2023IntroductionWelcome to this comprehensive guide on roller design and manufacturing analysis - everything you want to know is here. Rollers play a key role across industries, providing support, guidanc...view

EN

EN

ru

ru