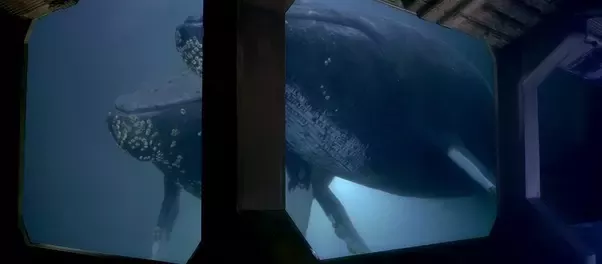

Transparent aluminum is a fascinating and futuristic material that has many advantages and disadvantages. It is a material that was first mentioned in the 1986 science fiction film Star Trek IV: The Voyage Home, where the crew of the USS Enterprise used it to construct a tank for transporting two humpback whales. However, transparent aluminum is also a real material that was invented in the 1980s by researchers at the Naval Research Laboratory and the Air Force Research Laboratory. The first transparent aluminum samples were produced in 1985 by sintering aluminum oxynitride powder at high temperature and pressure. The first commercial transparent aluminum products were introduced in the 1990s by Surmet Corporation, a company that produces and markets transparent aluminum products.

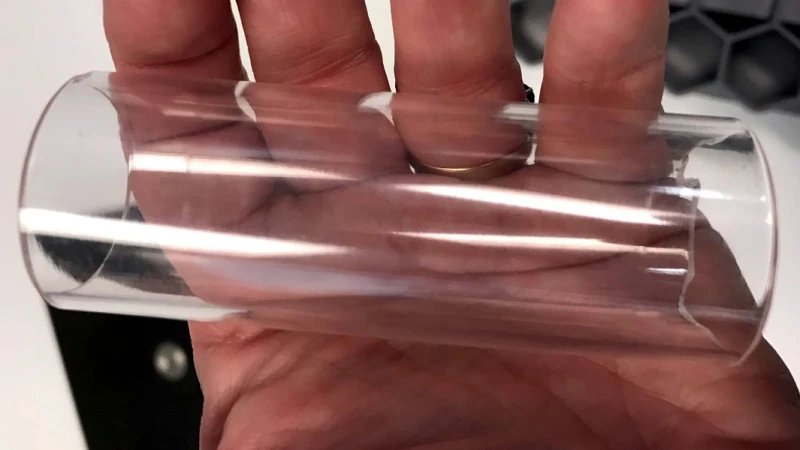

Transparent aluminum, also known as aluminum oxynitride or ALON, is a type of polycrystalline ceramic with a cubic spinel crystal structure. A polycrystalline ceramic is a material that consists of many small crystals that are bonded together. A cubic spinel crystal structure is a geometric arrangement of atoms that forms a cube with eight atoms at the corners and one atom in the center. The chemical formula of transparent aluminum is Al23O27N5, which means that it contains 23 atoms of aluminum, 27 atoms of oxygen, and 5 atoms of nitrogen.

Transparent aluminum is made from aluminum oxynitride powder, which is a mixture of aluminum, oxygen, and nitrogen. The powder is pressed into rubber molds and subjected to high pressure (15,000 pounds per inch) in a hydraulic press. The resulting material, which is opaque and molded, is then heated to 2000 °C and kept at this temperature for two days. The material is then cooled, ground, and polished to achieve transparency and strength.

Transparent aluminum has many advantages over other transparent materials, such as glass, sapphire, and diamond. Transparent aluminum is optically transparent (≥ 80%) in the near-ultraviolet, visible, and mid-wave-infrared regions of the electromagnetic spectrum. This means that it can transmit light of different wavelengths and colors, making it useful for optical and infrared systems. Transparent aluminum is also four times as hard as fused silica glass, 85% as hard as sapphire, and nearly 115% as hard as magnesium aluminate spinel. This means that it can resist scratches, cracks, and impacts, making it ideal for harsh environments. Transparent aluminum can also withstand temperatures up to 1200 °C and resist various acids, bases, and water. This means that it can maintain its stability and performance under extreme conditions, making it suitable for high-temperature and high-pressure applications.

The price of transparent aluminum depends on the size, shape, and quality of the product. According to Surmet Corporation, the price of transparent aluminum ranges from $10 to $15 per square inch for windows and plates, and from $3,000 to $5,000 per piece for domes and other complex

Transparent aluminum is a revolutionary material that has many potential applications in various industries, such as aerospace, military, and electrical.

• Infrared windows: Transparent aluminum can be used as infrared windows for sensors, cameras, and lasers, as it has high transparency and low absorption in the infrared region. Transparent aluminum windows can also withstand high temperatures, pressures, and impacts, making them ideal for harsh environments.

• Sensor components: Transparent aluminum can be used as sensor components, such as lenses, prisms, and mirrors, for optical and infrared systems. Transparent aluminum components can provide high optical quality, low dispersion, and high thermal stability, making them suitable for high-performance and high-reliability systems.

• Armor: Transparent aluminum can be used as armor for vehicles, aircraft, and personnel, as it has high strength and hardness, as well as high transparency. Transparent aluminum armor can provide protection against bullets, shrapnel, and blasts, as well as visibility and situational awareness. Transparent aluminum armor can also reduce the weight and thickness of the armor, compared to conventional glass or ceramic armor.

Above is the detailed knowledge of transparent aluminum, transparent aluminum is not widely used in the metal manufacturing industry at present, our understanding of transparent aluminum is still only on the surface, if you need CNC machining services for aluminum materials, you can contact Richconn.

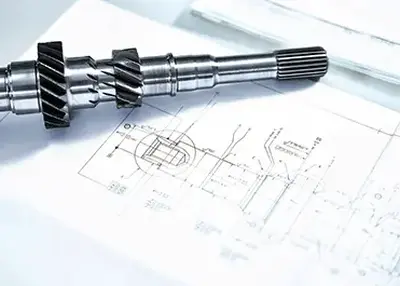

Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view

Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view Common Cheap CNC Material - An Overview of PlasticsJune 17, 2024Cheap CNC Material——ABSABS is one of the most common cheap CNC material, with good mechanical properties, excellent impact strength, high heat resistance, and good machinability.ABS has a low densit...view

Common Cheap CNC Material - An Overview of PlasticsJune 17, 2024Cheap CNC Material——ABSABS is one of the most common cheap CNC material, with good mechanical properties, excellent impact strength, high heat resistance, and good machinability.ABS has a low densit...view Thriving Outsourcing PartnershipsOctober 12, 2023Manufacturers now view outsourcing not just as a supplier relationship, but as a partnership. Lei Sheng, product manager at Richconn, explains why outsourcing projects with reliable partners make sense.view

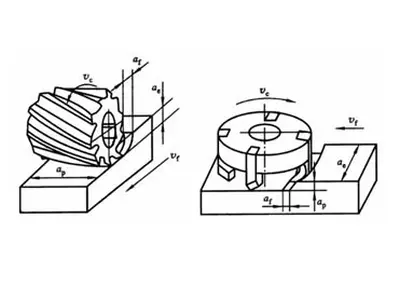

Thriving Outsourcing PartnershipsOctober 12, 2023Manufacturers now view outsourcing not just as a supplier relationship, but as a partnership. Lei Sheng, product manager at Richconn, explains why outsourcing projects with reliable partners make sense.view Process Analysis of CNC MachiningAugust 10, 2022CNC machining refers to the processing that the control system issues commands to make the tool perform various movements that meet the requirements, and express the shape and size of the workpiece in...view

Process Analysis of CNC MachiningAugust 10, 2022CNC machining refers to the processing that the control system issues commands to make the tool perform various movements that meet the requirements, and express the shape and size of the workpiece in...view UNF Threads vs UNC Threads and What Are UNF Threads and UNC ThreadsNovember 17, 2023In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.view

UNF Threads vs UNC Threads and What Are UNF Threads and UNC ThreadsNovember 17, 2023In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.view Top 12 CNC Machining Manufacturers in ChinaJune 6, 2024Among the numerous CNC machining services, why choose CNC machining manufacturers in China for your projects? This article will reveal the answer for you.view

Top 12 CNC Machining Manufacturers in ChinaJune 6, 2024Among the numerous CNC machining services, why choose CNC machining manufacturers in China for your projects? This article will reveal the answer for you.view

EN

EN

ru

ru