Boring is a very widely used process that involves drilling, reaming, boring, reaming and internal surface broaching tools. Compared to other machining, boring is a difficult process. It only relies on the adjustment of a blade (or blade seat) to be processed like H7, H6, such as micron-level holes. With the spread of machining centers, now the boring process only requires programming, operation by button, etc.. Because of this, there is a need for more simple, more convenient, more precise tool to ensure product quality. Here mainly from the point of view of tooling skills to analyze the boring process on the machining center.

Let's talk about the characteristics of boring on the machining center:

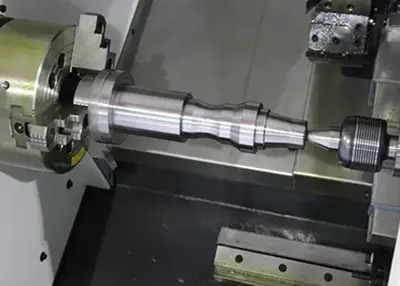

And lathe processing is different, machining center processing because the tool rolling, will not be able to grasp the situation of the tip of the tool in time to adjust the amount of feed and so on. Can not be like a CNC lathe that can only adjust the CNC button can change the processing diameter. This has become a great obstacle to the complete active processing. Because of this, so it is necessary to require the boring tool with fine-tuning organization or active compensation function, especially in fine boring according to the requirements of the public service is sometimes necessary in the micron level adjustment. In addition, the machining center boring because the direction of the chip outflow is constantly changing, so the tip of the tool, the cooling of the workpiece as well as the discharge of chips are much more difficult than the lathe processing.

Boring processing is the most common, but also the most headache is vibration. In the machining center on the vibration of the main reasons are as follows:

1) the rigidity of the system: including toolholder, boring bar, and the center of the rigidity of the articulation part. Because it is cantilever machining, especially small holes, deep holes and hard workpiece processing, the rigidity of the system is particularly important.

2) The dynamic balance of the tool detailed system: relative to the rolling axis of the tool detailed system, the tool itself has an unbalanced mass, when rolling due to the effect of unbalanced centrifugal force and lead to the onset of vibration. Especially in high-speed machining, the dynamic balance of the tool has a great impact.

3) Workpiece itself or the workpiece fixed rigidity: like some smaller, thinner parts because of its own lack of rigidity, or because of the shape of the workpiece can not use a reasonable fixture for adequate fixation.

4) Blade tip shape: the blade's front angle, tip radius, chipbreaker groove shape of the different cutting resistance is also different.

5) Cutting conditions: including cutting speed, feed, feed amount, as well as to the cutting oil methods and varieties.

6) machine spindle system: the rigidity of the machine spindle itself, the function of the bearings and gears, as well as the rigidity of the connection between the spindle and the shank.

In boring holes, the most important thing is to correctly clamp the tool on the machining center. In small hole boring, the center height of the tool is an important factor leading to tool failure. If the tool device is lower than the center height, will affect the processing function of the tool. The primary manifestations are:

1) The main rear angle of the cutting edge relative to the workpiece is reduced, resulting in the rear face of the tool contacting the workpiece, so that the conflict between the insert and the workpiece occurs, and when the insert is rotated, this conflict will further cause the tip of the tool to violate, resulting in the tool cutting deeper into the workpiece. The several parameters of the cutting edge have a great influence on the bump of cutting efficiency and the quality of machining. Increase the front angle, can reduce the plastic deformation of the front face kneading cutting layer, reduce the chip flow through the front of the conflict resistance, and then reduce the cutting force and cutting heat. But increase the front angle, at the same time will reduce the strength of the cutting edge, reduce the heat dissipation volume of the cutter head.

2) When the back angle of the tool decreases, the front angle of the insert relative to the workpiece also increases, which then causes the tool to scrape the workpiece, causing the tool to vibrate and damage the tool. This situation is more serious when boring small holes.

For this reason, it is advocated that the tool device should be slightly higher than the center height (but should be as close as possible to the center height). This can make the tool relative to the workpiece normal back angle increases, cutting conditions have been improved, if the processing of vibration, the tip of the tool will be down and to the center of the deflection, and then close to the center of the desired high. The tool can also be slightly withdrawn, reducing the possibility of chipping the workpiece. In addition, the front angle of the tool is reduced, which stabilizes the operating pressure. If the front angle is reduced to 0°, too much operating pressure will occur, resulting in tool failure. So in the boring, should choose a positive front angle of the boring tool, in the boring of 1mm hole, the diameter of the boring bar as long as 0.75mm or so, so that the tool to accept the cutting force is reduced.

In boring holes, the effective discharge of chips is critical. Processing, because the tool in the hole, cutting fluid is difficult to reach the cutting edge, the formation of chip discharge difficulties, affecting tool life. In order to deal with this problem, some tool makers began to announce a kind of cutting edge along the cutting edge with cooling groove inserts, so that the cutting fluid flows directly to the cutting edge, to avoid chip blockage and tool damage.

Commonly Used Boring Tool Types:

According to the processing content of the different boring tool selection benchmarks are not the same, in general, attention should be paid to the system's own rigidity, dynamic balance, flexibility, trust, ease of operation and longevity and cost.

The old one-piece boring tool is mainly used in the production line of batch products or specialized machines, but in fact, there are a variety of machine standards: NT, MT, BT, IV, CV, DV, etc. Even if the standard is the same, the size is also different. Even if the standard is the same, the size is different. Even if the standard and size are the same, it is possible that the shape of the spigot, thread is not the same, or the shape of the flange surface is not the same. All of these make the one-piece boring tool in the corresponding encounter great difficulties. Especially in recent years, the structure of the shopping mall, the shopping mall needs faster update speed of goods, the product cycle is increasingly shortened, which requires processing machinery as well as processing tools with more abundant flexibility. So most of the one-piece boring tools have disappeared from the factory.

Modular boring tool is the boring tool is divided into: the base shank, extenders, reducer, boring head, insert holder, and other parts, and then according to the detailed processing content (rough boring, fine boring; hole diameter, depth, shape; workpiece materials, etc.) for free combination. This not only greatly reduces the number of shanks, reduce the cost, but also be able to correspond to a variety of agile processing requirements, and extend the life of the tool as a whole. Now on the market there are a variety of modular boring tool system, their articulation methods are different. For example:

(1) BIG-KAISER method: it just rely on a taper of 15 ° taper screws to articulation, fixed when you only need a small hexagonal wrench, the operation is very convenient;

(2) Side-fixed type: this method of articulation is only to achieve the intention of fixed. The vast majority of its tightening force to the radial direction. Not only the end face of the articulation body can not be close, radial orientation will also change;

(3) Screw-in type: Although the end face is articulated, the phase of the tip of the tool on the circumference will change;

(4) rear tension type: the end face of the articulation and runout are better, but the operability is very poor.

Of course, the type of shopping center has far more than the above types, the user can be based on the need to select the required type of boring tool. As you can see, the modular boring tool has the advantage that the one-piece boring tool can not be compared. Of course, this also requires that the modular boring tool has high articulation accuracy and high articulation rigidity, as well as high repeatability and high reliability. In short, the modular boring tool system has great advantages, but it does not mean that as long as it is modular is good. It is necessary to measure from the articulation rigidity, precision, operability, price and other aspects.

Because in the high temperature, high pressure, high speed, and in corrosive fluid media operation parts, its use of difficult to process more and more materials, boring processing of the active level of slow on the machining accuracy of the requirements of more and more high. In order to get used to this situation, the development of boring tools will be the development and use of new tool materials, in order to better deal with the tool material hardness and strength of the opposition between; further development of the structure of indexable tools; progress in the production of tooling accuracy, reduce product quality of different products, and make the use of tools to complete the optimization.

Richconn is a company that focuses on providing customized precision parts machining with extensive machining experience and technical capabilities. If you're in need of boring machining, consider Richconn as a partner. Our team of professionals can meet your needs and provide high-quality CNC machining services.

Bead Blasting 101: How Does a Bead Blaster Work?November 2, 2023Bead blasting is an abrasive technique where media is projected onto a surface. How does a bead blaster work to ensure a smooth bead blasting process? Read on.view

Bead Blasting 101: How Does a Bead Blaster Work?November 2, 2023Bead blasting is an abrasive technique where media is projected onto a surface. How does a bead blaster work to ensure a smooth bead blasting process? Read on.view Wire EDM: Analyzing Precision Cutting TechnologyNovember 16, 2023The field of machining covers a variety of complex processes, of which wire EDM is an important one. This precision cutting method processes electrically conductive materials into high-precision parts by means of electric spark discharge. In this article, we will take an in-depth look at the working principles of wire EDM, its areas of application and its importance in manufacturing.view

Wire EDM: Analyzing Precision Cutting TechnologyNovember 16, 2023The field of machining covers a variety of complex processes, of which wire EDM is an important one. This precision cutting method processes electrically conductive materials into high-precision parts by means of electric spark discharge. In this article, we will take an in-depth look at the working principles of wire EDM, its areas of application and its importance in manufacturing.view Plastics For Medical Devices and ApplicationsOctober 17, 2023Are you designing medical parts? Just as there are countless medical procedures, there is now a seemingly endless abundance of polymer types. Which ones are best suited for medical applications? Good question.view

Plastics For Medical Devices and ApplicationsOctober 17, 2023Are you designing medical parts? Just as there are countless medical procedures, there is now a seemingly endless abundance of polymer types. Which ones are best suited for medical applications? Good question.view What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view

What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view Alloy Steel vs Carbon Steel: Which Is Better?September 5, 2023Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific ...view

Alloy Steel vs Carbon Steel: Which Is Better?September 5, 2023Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific ...view What Products Can Be Customized with a Five Axis CNC Machining Center?August 14, 2023A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, mi...view

What Products Can Be Customized with a Five Axis CNC Machining Center?August 14, 2023A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, mi...view

EN

EN

ru

ru