CNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increased in recent years due to their ability to increase productivity, reduce waste and improve efficiency.

Machining centers are critical outfit for machining essence corridor and factors in addition to their primary purpose of bones manufacture. As an illustration, machining centers in the machine assiduity are used for effective grinding and drilling of machine corridor as well as for making dies for body factors.

Vertical machining centers (VMCs) are used for milling, drilling and turning. They have a spindle that is positioned at the center of the machine and can be moved up and down by an electric or hydraulic power system. The column supporting the spindle is connected to this power system as well so that it can move with it.

Horizontal machining centers are used to mill parts in a horizontal plane. They can be used to machine large parts, such as aircraft fuselages or tank hulls. Horizontal machining centers are more accurate than vertical machining centers and are used for high volume production of small components or low volume production of large components.

You can use a universal machining center to machine a wide range of CNC machining materials. They're commonly used in industries like aerospace, automotive, and medical, but can also be found in other sectors such as electronics and consumer goods. These machines are often used for large parts and components—such as engine crankshafts or transmission housings—as well as smaller components that require complex geometries.

CNC is used in a variety of industries. The aerospace industry typically uses CNC to create parts that are too complex to make by hand, while the medical industry uses CNC medical parts to create custom implants and prosthetics. In the automotive industry, CNC can be used to create custom parts for vehicles or as a way to save time and money when manufacturing parts.

CNC machining services are used in a variety of industries, from aerospace and medical to automotive. They're also used for non-industrial purposes such as custom furniture and architectural milling. As a leading China CNC factory, Richconn can provide you with quality OEM CNC machining in China and custom precision machining for varied needs. Feel free to contact us at any time.

Analysis of Process Characteristics for CNC Machining PartsApril 4, 2023Choose the appropriate machine tool based on the material, contour shape, machining accuracy and other factors of the processed workpiece. Develop a machining plan, determine the processing sequence o...view

Analysis of Process Characteristics for CNC Machining PartsApril 4, 2023Choose the appropriate machine tool based on the material, contour shape, machining accuracy and other factors of the processed workpiece. Develop a machining plan, determine the processing sequence o...view CNC Machining and AI: How Artificial Intelligence is Impacting the FieldOctober 25, 2023Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:view

CNC Machining and AI: How Artificial Intelligence is Impacting the FieldOctober 25, 2023Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:view All the Information You Need to Know About Polishing Surface FinishMarch 1, 2024Here is all the information. Learn more about the necessary details to guarantee your project's success. Check it out.view

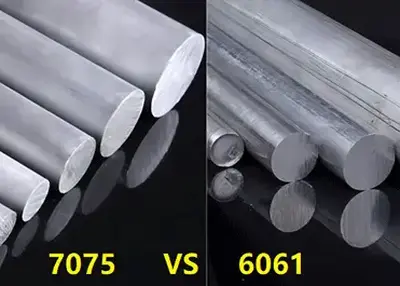

All the Information You Need to Know About Polishing Surface FinishMarch 1, 2024Here is all the information. Learn more about the necessary details to guarantee your project's success. Check it out.view Comparison of 7075 Aluminum Alloy vs 6061 Aluminum AlloyNovember 27, 2023Aluminum alloy is a widely used metal material with the advantages of light weight, high strength, corrosion resistance and recyclability. There are many types of aluminum alloys, and different alloying elements and heat treatment processes affect the properties and uses of aluminum alloys.view

Comparison of 7075 Aluminum Alloy vs 6061 Aluminum AlloyNovember 27, 2023Aluminum alloy is a widely used metal material with the advantages of light weight, high strength, corrosion resistance and recyclability. There are many types of aluminum alloys, and different alloying elements and heat treatment processes affect the properties and uses of aluminum alloys.view Spray painting, powder spraying, electrophoresis: three common surface treatment methodsMarch 6, 2024Spray painting is a common way of surface treatment, its principle is to use air pressure to spray paint from the nozzle, forming tiny droplets, that and evenly attached to the surface of the painted object.view

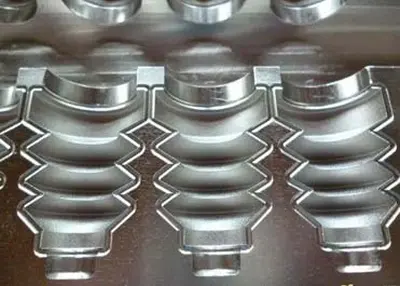

Spray painting, powder spraying, electrophoresis: three common surface treatment methodsMarch 6, 2024Spray painting is a common way of surface treatment, its principle is to use air pressure to spray paint from the nozzle, forming tiny droplets, that and evenly attached to the surface of the painted object.view Must-Read for Procurement Professionals! 2023 Report on China's Rubber Molds and Parts IndustryAugust 16, 2023Overview: This report provides an in-depth analysis of the development trends, competitive landscape, and key characteristics of China's rubber molds and parts industry in 2023. It serves as an im...view

Must-Read for Procurement Professionals! 2023 Report on China's Rubber Molds and Parts IndustryAugust 16, 2023Overview: This report provides an in-depth analysis of the development trends, competitive landscape, and key characteristics of China's rubber molds and parts industry in 2023. It serves as an im...view

EN

EN

ru

ru