Titanium has carved an impressive niche for itself within a myriad of industries and applications, all thanks to its extraordinary and unparalleled properties. The element of Titanium is symbolized by Ti and holds the atomic number 22. If you've ever pondered what is titanium used for; in pursuit of insights into titanium applications, how is titanium used, and the common uses of titanium, you've landed on the right place.

Titanium is relatively abundant in the Earth's crust. It is typically found in minerals like ilmenite, rutile, and titanite, which are widespread in geological formations. It was first discovered in 1791 by the English geologist William Gregor. In 1795, the German chemist Martin Heinrich Klaproth officially named the element "titanium."

Symbol and Atomic Number: Titanium is represented by the chemical symbol Ti and has the atomic number 22.

Appearance: It is a metallic element with a distinctive silvery-gray color.

Strength-to-Weight Ratio: Titanium boasts an exceptional strength-to-weight ratio, making it prized for various applications.

Corrosion Resistance: Titanium exhibits remarkable resistance to corrosion, even when exposed to water, air, and a wide range of chemicals.

High-Temperature Tolerance: It can withstand high temperatures and extreme pressures, making it suitable for demanding environments.

In 1910, titanium was isolated in pure form by Matthew A. Hunter, an American metallurgist, who reduced titanium tetrachloride with sodium in a steel cylinder.

The first uses of titanium were in laboratory experiments and chemical applications. Titanium was used to make electrodes for electroplating and welding, as well as catalysts for the production of synthetic rubber and other organic compounds. Titanium was also used to make alloys with other metals, such as iron, copper, and aluminum, to improve their strength and corrosion resistance.

During World War II, titanium was recognized as a strategic metal for military and aerospace applications. Titanium was used to make armor plates, aircraft parts, rockets, missiles, and submarine hulls. After the war, titanium became more widely available and affordable due to the development of new extraction and fabrication methods. Titanium was used to make jet engines, propellers, landing gears, and other components for high-speed aircraft and spacecraft.

As people dig further into what titanium used for over time, the applications of titanium have become increasingly extensive, ranging from everyday consumer goods to cutting-edge technologies.

When soaring through the skies or hurtling into space, weight is a critical factor. Titanium alloys provide a compelling solution, as they offer the strength required to withstand extreme stresses while remaining remarkably lightweight. This unique combination not only enhances fuel efficiency but also enables these air vehicles to reach greater altitudes and velocities.

On another hand, Submarines and ships benefit immensely from titanium's corrosion resistance, a property that is particularly vital in the harsh, corrosive environment of the sea. Unlike traditional metals that succumb to rust and deterioration, titanium stands strong, ensuring the longevity and reliability of marine vessels and equipment.

Titanium's chemical properties have found a pivotal role as a catalyst in the production of polymers. Titanium is a metal that has the ability to form strong bonds with oxygen atoms. This property makes titanium an effective catalyst for the polymerization of various monomers, such as lactide, ethylene, propylene, and styrene. Titanium catalysts can enhance the rate, selectivity, and efficiency of the polymerization reactions, as well as influence the molecular weight, stereochemistry, and architecture of the resulting polymers.

One of the most common types of titanium catalysts is the Ziegler-Natta catalyst. Ziegler-Natta catalyst is based on titanium compounds supported on inert materials, such as magnesium chloride or silica. It is used in combination with organoaluminum compounds, such as triethylaluminum or methylaluminoxane, as cocatalysts. This catalyst is widely used in the industrial production of polyethylene and polypropylene, two of the most important and widely used plastics.

Titanium is bringing durability and sophistication to items we use on a daily basis.

Eyeglass Frames

Titanium frames not only offer a stylish and sleek look but also boast incredible strength and corrosion resistance. This ensures that your eyeglasses maintain their form and appearance despite exposure to moisture and the elements, making them a long-lasting investment for your visual needs.

Watches and Jewelry

The use of titanium in watchcases and jewelry has gained popularity due to its lightweight nature and resistance to tarnishing.

Bicycles and Sports Equipment

Titanium's low density makes it a favorite in the world of sports. Bicycles made with titanium frames offer a smooth, comfortable ride without compromising on strength.

Other sports equipment like tennis rackets and golf clubs benefit from titanium's ability to enhance performance without adding unnecessary weight.

As we peer into nuclear waste management, titanium emerges as a compelling candidate for a pivotal role.

The safe disposal of nuclear waste is one of the most pressing challenges facing humanity in the 21st century. Finding a reliable, long-term solution for the isolation of these materials is paramount. Titanium's corrosion resistance is nearly unparalleled among metals, making it exceptionally well-suited to withstand the harsh chemical conditions within nuclear waste repositories.

Titanium's ability to form stable compounds with radioactive elements adds another layer of protection. In such environments, where highly corrosive substances can compromise containment structures, titanium's stability is one of the best fits. Titanium's longevity also ensures the durability of containment systems, reducing the need for costly maintenance and replacement. This long-term approach to waste management contributes to cost-effectiveness and provides a sustainable solution for future generations.

Titanium is a preferred choice for electroplating electrodes, welding materials, and equipment used in chlor-alkali production. In chemical, oil, and gas industries, as well as power generation, titanium pipes, valves, and heat exchangers provide long-lasting performance.

Electroplating, a technique used to coat surfaces with a layer of metal, relies on electrodes to facilitate the process. Besides, welding, a fundamental industrial process, also benefits from titanium's presence. For electroplating, Richconn as a prominent player in the electroplating industry, recognizes the value of titanium in achieving impeccable plating results. They utilize titanium electrodes to ensure durability and consistent performance, factors crucial in delivering high-quality electroplated products. As for welding, Richconn, renowned for its expertise in welding materials, incorporates titanium alloys into its product line.

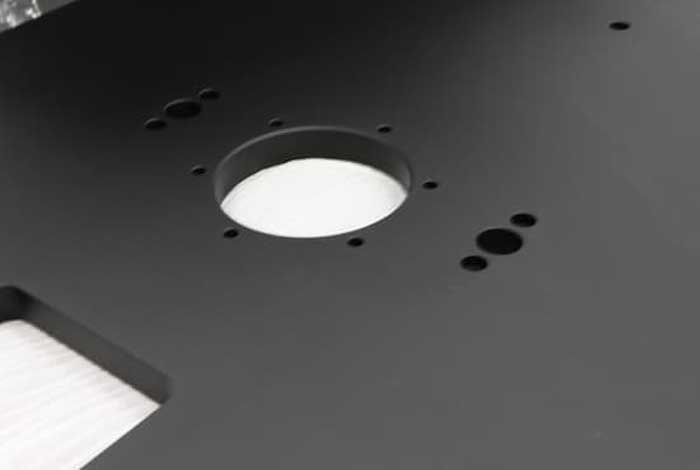

In the chemical, oil, and gas industries, where harsh and corrosive environments are the norm, titanium shines as a CNC machining material choice. It is used in the manufacturing of pipes, valves, and heat exchangers, components critical for safe and efficient operations. Titanium-based components in power generation such as pipes, valves, and heat exchangers are enhancing the longevity and reliability of power plants as well.

Titanium's remarkable properties, including exceptional strength-to-weight ratio, corrosion resistance, and high-temperature tolerance, have Versatile applications across the board. From aerospace engineering to its role in shaping the plastics industry, titanium has left an indelible mark on modern technology and manufacturing. As we peer into the future, the unwavering strength, corrosion resistance, and adaptability of titanium continue to pave the way for groundbreaking solutions in fields as diverse as nuclear waste management and industrial processes.

If you have any questions about titanium related to OEM precision CNC machining, click here for assistance!

Beyond Aesthetics: The Practical Benefits of Blackening Surface TreatmentDecember 4, 2023When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment...view

Beyond Aesthetics: The Practical Benefits of Blackening Surface TreatmentDecember 4, 2023When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment...view All About Hardness Definition: Types, Testing Methods & UnitsOctober 12, 2023Here is an in-depth overview of hardness definition. Follow this article to learn metal hardness for different materials and choose the suitable one for your project.view

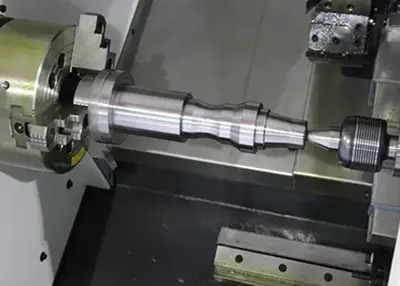

All About Hardness Definition: Types, Testing Methods & UnitsOctober 12, 2023Here is an in-depth overview of hardness definition. Follow this article to learn metal hardness for different materials and choose the suitable one for your project.view What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view

What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view Aluminium Anodizing Services Process FlowApril 25, 2023The general process of anodizing aluminum and aluminum alloys can be roughly divided into pre-treatment, anodizing, and post-treatment (non-decorative products can skip coloring).Mechanical pre-treatm...view

Aluminium Anodizing Services Process FlowApril 25, 2023The general process of anodizing aluminum and aluminum alloys can be roughly divided into pre-treatment, anodizing, and post-treatment (non-decorative products can skip coloring).Mechanical pre-treatm...view Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view

Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view Unveiling the Power of Galvanized Materials: Your Ultimate GuideSeptember 28, 2023Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization.view

Unveiling the Power of Galvanized Materials: Your Ultimate GuideSeptember 28, 2023Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization.view

EN

EN

ru

ru