What are the processing principles of precision CNC machining? What safety precautions are there when performing precision CNC machining?

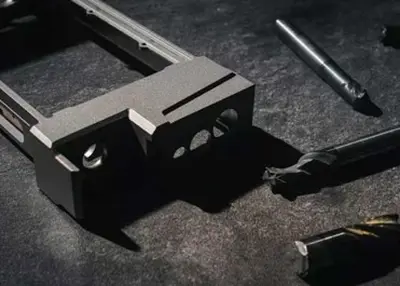

(1) In order to ensure the machining accuracy, it is best to carry out rough and finish machining separately. Because during rough machining, the cutting amount is large, the cutting force and clamping force on the workpiece are large, the heat generation is large, and the machined surface has obvious work hardening phenomenon, and there is a large internal stress inside the workpiece. If it is carried out continuously, the accuracy of the parts after precision CNC machining will be quickly lost due to the redistribution of stress. For some parts that require high machining accuracy. After rough machining and before finishing, a low temperature annealing or aging treatment process should be arranged to eliminate internal stress.

(2) Choose equipment reasonably. Rough machining is mainly to cut off most of the machining allowance, and does not require high machining accuracy. Therefore, rough machining should be carried out on a machine tool with high power and low precision, and the finishing process requires higher precision machine tools. Machine tool processing. Rough and fine machining are processed on different machine tools, which can not only give full play to the equipment capabilities, but also prolong the service life of precision machine tools.

(3) In the precision CNC machining process route, a heat treatment process is often arranged. The location of the heat treatment process is arranged as follows: In order to improve the cutting performance of metals, such as annealing, normalizing, quenching and tempering, etc., it is generally arranged before precision CNC machining. In order to eliminate internal stress, such as aging treatment, quenching and tempering treatment, etc., are generally arranged after rough machining and before finishing machining. In order to improve the mechanical properties of parts, such as carburizing, quenching, tempering, etc., are generally arranged after precision CNC machining. If there is a large deformation after heat treatment, the final processing procedure must be arranged.

(1) Easy to operate, reduce walking back and forth, and avoid unnecessary bending and tiptoe movements.

(2) The positioning is accurate and reliable, preventing misoperation due to slight vibration.

(3) The movement direction of the operating parts of the precision CNC machining machine tool equipment and the movement direction of the operated parts must comply with the regulations, and there are simple symbols.

(4) Install necessary interlocking mechanisms to prevent uncoordinated actions of operating parts and accidents caused by uncoordinated operations by multiple people.

(5) The structure and arrangement of handles, handwheels and buttons must comply with the regulations. The start button should be installed in the casing or equipped with a guard ring to prevent accidental touch. The hand wheel and handle installed on the shaft will rotate with the shaft and hurt people when the knife is automatically fed, so an automatic ejection device should be installed.

Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view

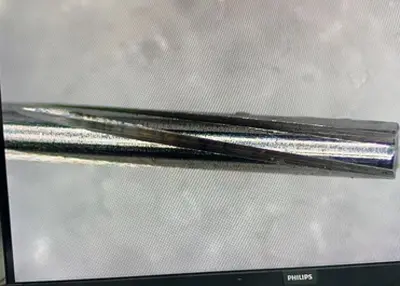

Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view Case Study 2023: Improving the Yield of Precision Mandrel Parts ProductsDecember 22, 2023Key production process design and high-quality processing give us the basic characteristics that customers like, and we can also provide you with the services you need.view

Case Study 2023: Improving the Yield of Precision Mandrel Parts ProductsDecember 22, 2023Key production process design and high-quality processing give us the basic characteristics that customers like, and we can also provide you with the services you need.view What Is Prototype Manufacturing? Process, Benefits, and Vital TipsOctober 25, 2023A good understanding of prototype manufacturing will help you make the best choice for your project. Learn more about it from this passage.view

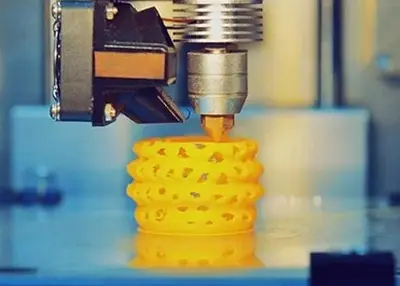

What Is Prototype Manufacturing? Process, Benefits, and Vital TipsOctober 25, 2023A good understanding of prototype manufacturing will help you make the best choice for your project. Learn more about it from this passage.view Affordable 3D Printing Service: Tips for Cost-Effective SolutionsSeptember 1, 2023Whether you're an entrepreneur seeking rapid prototyping or a hobbyist looking to bring your creative ideas to life, 3D printing service offers a world of possibilities. However, have you ever tho...view

Affordable 3D Printing Service: Tips for Cost-Effective SolutionsSeptember 1, 2023Whether you're an entrepreneur seeking rapid prototyping or a hobbyist looking to bring your creative ideas to life, 3D printing service offers a world of possibilities. However, have you ever tho...view Types of Springs | Guidelines, Spring Types, and ApplicationsOctober 18, 2023Springs play a crucial role in various products, providing motion and shock absorption. This article will show you different types of springs and how to choose the right one.view

Types of Springs | Guidelines, Spring Types, and ApplicationsOctober 18, 2023Springs play a crucial role in various products, providing motion and shock absorption. This article will show you different types of springs and how to choose the right one.view 3D Printing Materials GuideOctober 9, 20233D printing, also known as additive manufacturing, has a wide range of materials available for creating objects. The choice of material depends on factors such as the desired properties of the final o...view

3D Printing Materials GuideOctober 9, 20233D printing, also known as additive manufacturing, has a wide range of materials available for creating objects. The choice of material depends on factors such as the desired properties of the final o...view

EN

EN

ru

ru