Gel electrophoresis, a foundational technique in the field of molecular biology, serves as a crucial tool for scientists to unravel the complexities of genetic material. At the heart of this precision-driven process stands an often-overlooked hero – electrophoresis metal coating. This blog aims to explore in greater detail the indispensable role played by electrophoresis metal coating in enhancing the accuracy and efficiency of gel electrophoresis.

Gel electrophoresis involves the separation of molecules, typically DNA fragments, based on their size and charge. The precision of this separation is paramount for the accurate analysis of genetic material. Electrophoresis metal coating, although often unnoticed, plays a pivotal role in achieving and maintaining this precision.

Electrophoresis metal coating entails the application of a thin layer of metal – commonly platinum or gold – onto the surfaces of electrodes used in gel electrophoresis. This coating acts as a catalyst, facilitating a more controlled and uniform flow of electrical current during the process. The consequence is a heightened level of precision in guiding molecules through the gel matrix, resulting in a sharper and more accurate separation of genetic material.

The coated electrodes create a conducive environment for the migration of charged molecules, ensuring a consistent and predictable movement through the gel matrix. This controlled environment minimizes irregularities that could lead to distorted or inaccurate separation of DNA fragments. In essence, electrophoresis metal coating transforms the electrodes into finely-tuned instruments, orchestrating the intricate dance of genetic material with precision.

In the realm of gel electrophoresis, particularly when the goal is the separation of DNA fragments based on size, the role of electrophoresis metal coating becomes even more crucial. The even electrical field created by the coated electrodes becomes a guiding force, minimizing deviations and allowing for a highly accurate sizing of DNA fragments. This precision is especially vital in applications ranging from genetic research to forensic analysis, where reliable and reproducible results are imperative.

Beyond its role in precision, electrophoresis metal coating significantly contributes to the overall efficiency of gel electrophoresis. The smooth and conductive surface provided by the coating ensures a consistent electrical current, reducing the risk of uneven migration of molecules. This efficiency translates into faster and more reliable results, saving researchers valuable time and resources.

Researchers and scientists benefit from the increased efficiency in data generation, as electrophoresis metal coating minimizes the potential for variations in migration patterns that could lead to ambiguous or inconclusive results. The reliability and reproducibility of data become paramount, especially in longitudinal studies or experiments requiring consistency.

As we journey into the intricate world of molecular biology, electrophoresis metal coating emerges as a silent yet indispensable player in the quest for precision. Its subtle yet transformative influence on the accuracy, efficiency, and reliability of gel electrophoresis sets a higher standard for molecular analysis.

In the ongoing pursuit of unraveling the mysteries of genetic material, electrophoresis metal coating stands as a testament to the commitment to precision in scientific research and molecular diagnostics. As technologies advance and scientific inquiries become more nuanced, the role of this unassuming coating will continue to be pivotal in shaping the landscape of molecular biology, elevating the field to new heights of accuracy and understanding.

Deburring Guide: Everything You Need to Know about DeburringNovember 2, 2023This deburring guide helps you get the best understanding of the deburring process. Learn more to eliminate the part burrs.view

Deburring Guide: Everything You Need to Know about DeburringNovember 2, 2023This deburring guide helps you get the best understanding of the deburring process. Learn more to eliminate the part burrs.view 5 Important Facts About 5 Axis Machining | Basics Information, Benefits, Limitations, Applications & TipsFebruary 20, 20245 axis CNC machining technology is important in manufacturing. Learn more about its basics, pros &cons, applications, and tips to enhance your project performance.view

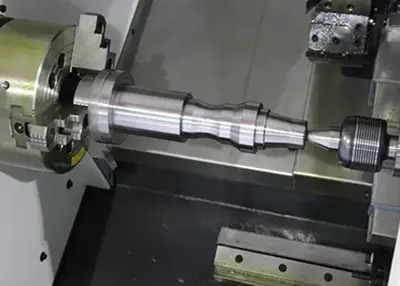

5 Important Facts About 5 Axis Machining | Basics Information, Benefits, Limitations, Applications & TipsFebruary 20, 20245 axis CNC machining technology is important in manufacturing. Learn more about its basics, pros &cons, applications, and tips to enhance your project performance.view What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view

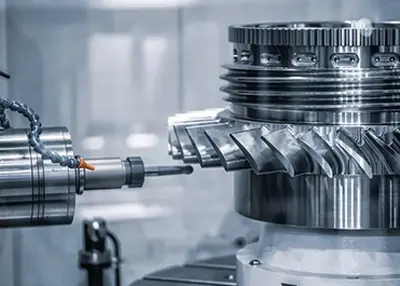

What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view

Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view The Importance of Material Science in Component Interaction.October 18, 2023Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.view

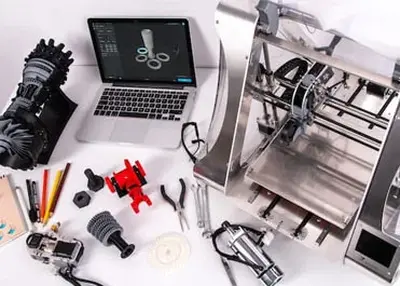

The Importance of Material Science in Component Interaction.October 18, 2023Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.view How Much Do 3D Prints Cost: An In-Depth Guide to ExpensesAugust 15, 20233D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arise...view

How Much Do 3D Prints Cost: An In-Depth Guide to ExpensesAugust 15, 20233D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arise...view

EN

EN

ru

ru