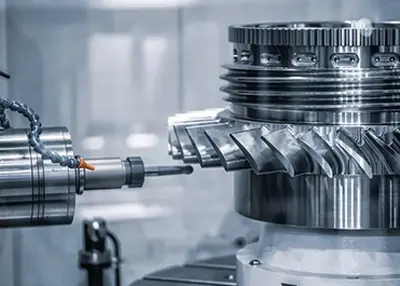

CNC machining technology is always changing and improving. If you work in manufacturing or machining, you've probably heard about the concept of 5-axis computer numerical control (CNC) machines. The 5axis CNC machine exemplifies how sophisticated computational control can enable unparalleled manufacturing capabilities, and it is truly fascinating to observe its movements and rotations around its axes. Learn about 5-axis CNC machining, its benefits and limitations, and why a 5-axis machine may fit your needs in this guide.

The normal functioning of CNC machines involves the movement of cutting tools across three axes of Z, X, and Y simultaneously. The five axes’ machines have two more axes accessible, which are namely A and B, which enhance their capability to manipulate and fabricate complex and intricate components. The increasing usage of five-axis machines can be attributed to their ability to streamline production timelines by reducing manufacturing time.

The usage of a spinning cutting fitting allows the CNC machines to rapidly achieve desired part geometries. With the table being able to position and rotate along all five axes, the amount of stress on the cutting tools is minimized, consequently prolonging the lifespan of the CNC machine.

To help understand the axes in a CNC 5 axis milling machine, Let's delve into the concept of axes in a 5 axis CNC milling machine. The axis count in machining refers to the number of directions in which the cutting tool (or raw material) can move to shape the desired product. For example, traditional CNC machines are typically equipped with three axes, limiting the movement of their cutting tools to the X, Y, and Z axes.

The cutting tool includes:

X-axis: The operator can move the worktable to the left or right.

Y-axis: The table can move forward or backward.

Z-axis: The operator can move the head of the cutting tool up or down to adjust the depth of the cut.

In addition to moving along the X, Y, and Z axes, a 5 axis machining center also has two rotary axes, known as the A-axis and B-axis. This configuration enables all five axes to work simultaneously to carry out intricate cutting maneuvers. Unlike machines with a fixed tool head, the presence of the 4th and 5th axes allows the cutting tool to approach the workpiece from multiple directions. By utilizing a single setup, an operator can machine various sides of a component. 5thaxis should be noted that certain machines may also feature a C-axis for rotation around the Z-axis.

These specialized 5-axis machines offer a wide range of motion to produce highly complex shapes. For instance, creating a partial cavity or an overhang typically requires repositioning the part midway through the process on a standard 3-axis horizontal machining center. In contrast, with a 5-axis CNC machine, one can input the instructions and avoid the need to adjust the material or tool positioning. This results in reduced setup times, enhanced capability for manufacturing intricate components, and improved repeatability.

The main variance between the types of 5 axis machine is where the rotational axes appear on the machine. The three major types of 5-axis CNC machines are:

Rotary Table and Pivoting Spindle Head

This machine features a B-axis, 360-degree rotary table beneath the workpiece, providing a workspace of 50 inches in diameter and height. It is designed for components like holed cylinders with angled holes, such as turbine housings. Unlike other 5-axis CNC machines requiring multiple axis movements to reach different hole positions on a cylindrical component, this machine only needs one axis motion thanks to its pivoting head/rotary table configuration. This results in a more repeatable drilling process with reduced chances of position errors. Moreover, the limited rotational axis motion of the material allows for efficient machining of large parts, especially tall cylindrical materials.

Double Rotary Table

This CNC machine features a large primary table that allows for flexibility in positioning the A-axis unit. Efficient programming requires precise knowledge of the A-axis table's position relative to the B pivot. Ideal for holed cylindrical components, this machine may require manual orientation of the A-axis unit. While it can handle large parts if the axis is correctly positioned, its material size limitations are more pronounced compared to enclosed machines. Despite restrictions on material size due to the A-axis position, the machine's extensive XYZ movement makes it suitable for long tool extensions and unconventional angles.

Trunnion Table Machine

The trunnion setup, known as the Table-Table configuration, features both rotary axes in the trunnion table with a stationary head. It is user-friendly for programmers transitioning from standard three-axis CNC machining. This setup allows for easy material positioning and offers superior undercut capabilities compared to swivel head designs. The trunnion setup also maximizes work volume by providing the full range of motion for the X, Y, and Z axes. It is suitable for heavy metal removal and offers high torque at low RPMs with belt-driven or geared spindles, reducing the risk of head misalignment during machining.

The benefits of 5-axis CNC machining centers are numerous, offering advanced capabilities that contribute to enhanced precision, flexibility, and efficiency in manufacturing processes. Listed below are the key benefits of 5-axis CNC machines:

Cost-effective Way of Manufacturing Complex Parts

Using 5-axis CNC machines is a cost-effective solution for manufacturing intricate parts. These machines streamline the machining process, boosting productivity by allowing complex designs to be machined in a single setup.

By opting for 5-axis CNC machines, you can save time and reduce labor costs associated with re-fixture. Minimizing the need for operator intervention decreases overall running expenses and minimizes the risk of errors during loading.

Additionally, 5-axis CNC machines offer various cost-saving benefits, such as reducing floor space requirements, maximizing flexibility and spindle utilization, cutting down on expensive fixtures, and lowering inventory investments. The ability to machine complex parts in fewer setups not only saves money but also allows staff resources to be reallocated efficiently.

Enhanced Surface Quality and Tool Longevity

The versatility of 5-axis machining enables the manipulation of parts through rotations and tilting, offering access to features that a 3-axis machine cannot reach. This capability allows for the potential use of shorter cutting tools operating at higher speeds, reducing vibration and leading to superior surface finishes.

By minimizing tool deflection, vibration, and heat generation, 5-axis machines contribute to prolonged tool life. Optimization of cutting angles and reduced tool re-entry paths helps to mitigate tool wear. Additionally, the heightened precision and accuracy of 5-axis CNC machines minimize tool chatter and ensure more consistent cutting forces, ultimately enhancing tool longevity.

Increased Precision in Parts

Part precision is elevated as there is no requirement to transfer the same workpiece across multiple workstations.

Moreover, by eliminating multiple setups and additional operations, the potential for expensive errors and misalignments is minimized. This streamlined process also decreases waste material, resulting in enhanced cost efficiency.

Faster Machining

The utilization of multiple axes allows for the complete machining of the workpiece in a single operation rather than multiple steps, leading to an increased output capacity at a quicker pace. By saving time for users, 5-axis machines also result in direct cost savings.

5-axis CNC machines are capable of simultaneous movement along five axes, enabling intricate and complex cuts to be achieved in a single setup. This eliminates the necessity for multiple setups and significantly reduces machining time.

With 5-axis machines, operations can be carried out from various angles without the need for frequent tool changes. This eliminates downtime from tool changes and minimizes disruptions to the machining process.

While 5-axis CNC machining centers offer numerous advantages, it's important to consider some limitations associated with this advanced machining technology.

High Initial Costs

Acquiring a 5-axis CNC machine and necessary software incurs substantial upfront costs, surpassing those of 3-axis machining centers. Additionally, maintaining the machine poses more challenges compared to traditional tools, further elevating the overall machining expenses for 5-axis components.

Demands Complex Programming

Typically, 5-axis machining necessitates more intricate programming, requiring operators to undergo advanced training. However, many machine tool manufacturers are incorporating features to streamline and simplify programming processes to some extent.

Higher Skill Requirement

To fully utilize a 5-axis CNC machine, operators must possess significant experience and expertise.

Given that these machines can perform intricate movements and complex machining tasks from multiple angles, operators must possess in-depth knowledge of the machine's capabilities and the fundamentals of 5-axis machining.

Proficient technicians can effectively configure the machine, program necessary tool paths, and oversee a seamless machining process. Nonetheless, the heightened skill demand for operating 5-axis machines can lead to increased labor expenses for businesses. Recruiting and retaining highly skilled operators typically comes at a higher cost, influencing overall operational expenditures.

5-axis CNC machines are utilized across various industrial and commercial sectors. Some typical applications of 5-axis machinery include:

Energy Production

In the energy sector, intricate and sophisticated components are frequently needed for applications like solar power systems and power stations. The increasing adoption of 5-axis machining technology enables precise CNC machining of intricate and precise parts for energy-related equipment. These components are manufactured to be robust and offer stability to operational environments.

Healthcare

Due to their high precision capabilities, 5-axis CNCs are well-suited for crafting intricate medical equipment, devices, and implants.

Aerospace

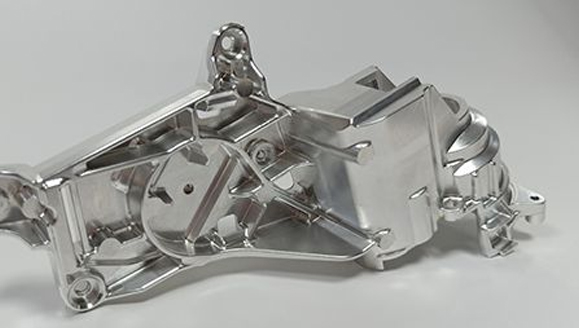

The aviation and aerospace fields require precisely machined components with sleek, curved features.

Automotive

5-axis CNC machines are efficient in manufacturing intricate parts such as gearboxes and drive axles.

If you’re considering adding 5-axis CNC machining to your business, here are a few recommendations:

Consider Your Needs

Uncertain about choosing between a 5-axis router or a continuous 5-axis machine? Evaluate the nature of your projects. Typically, 5-axis CNC machines are more suitable for intricate contour surface machining, while 3+2 machining is predominantly utilized for flat surface processing. If you require tighter tolerances and aim to manufacture intricate final products, continuous 5-axis machining is likely the better option. Additionally, consider the specific additional features and software integration you require.

Research Your Choices

Subsequently, explore local dealers and compare prices for available options. You must determine whether it is economically advantageous to purchase a standard machine or invest additional funds in a custom design tailored to your workshop's requirements. Given that 5-axis models come with a higher price tag compared to 3-axis CNC machines, numerous businesses choose CNC financing as a method to gradually repay the machine cost over time.

Prepare for Maintenance

Although 5-axis machines offer labor cost savings, they necessitate consistent maintenance. Planning for maintenance costs is essential to guarantee the machine's optimal performance. Additionally, budgeting for ongoing training for yourself or your staff is necessary to acquire the skills needed to operate a 5-axis machine effectively.

With a detailed explanation of 5-axis machining provided, a comprehensive understanding of 5-axis CNC machining has been achieved. Now is the time to take control of the manufacturing process. 5-axis CNC machines streamline fabrication procedures, ensuring quicker and cost-effective production, as well as enhancing precision and accuracy. However, they may not be suitable for all designs. For instance, 3- or 4-axis CNC machines could be more appropriate and cost-efficient for precise cutouts, holes, and cavities.

Hence, it is crucial to consult a CNC machining expert before initiating your project. Richconn, a prominent global CNC machining services provider, offers robust 5-axis CNC machining services for the production of high-precision CNC machined parts. The team possesses the necessary tools and expertise to accomplish this task efficiently. From metal components to intricate assembly features, Richconn excels in flawlessly executing projects and delivering top-notch results promptly.

Customer satisfaction is paramount at Richconn, with all services offered at competitive rates. Simply reach out to us or send your design file today to receive an instant quote and kickstart the project without delay.

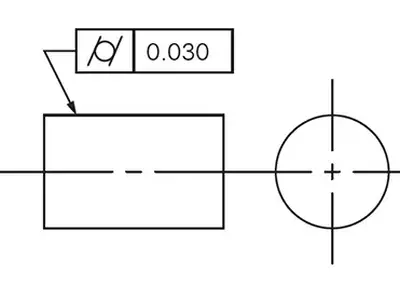

Unlocking Precision: Mastering Cylindricity for Engineering ExcellenceNovember 21, 2023In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.view

Unlocking Precision: Mastering Cylindricity for Engineering ExcellenceNovember 21, 2023In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.view What Is a Shaft?October 30, 2023A shaft is basically a rotating part of any machine, having a circular cross-section, which is used to transmit power from one part to another or from a power generating machine to a power absorbing machine. To transmit power, one end of the shaft is connected to the power source and the other end is connected to the machine. Shafts can be solid or hollow as per requirement, hollow shafts help in reducing weight and provide advantages.view

What Is a Shaft?October 30, 2023A shaft is basically a rotating part of any machine, having a circular cross-section, which is used to transmit power from one part to another or from a power generating machine to a power absorbing machine. To transmit power, one end of the shaft is connected to the power source and the other end is connected to the machine. Shafts can be solid or hollow as per requirement, hollow shafts help in reducing weight and provide advantages.view Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view

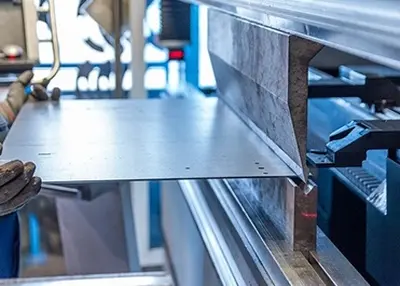

Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view 5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view

5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view CNC Machining Technology and ProcessJuly 27, 2023CNC Machining TechnologyCNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly compl...view

CNC Machining Technology and ProcessJuly 27, 2023CNC Machining TechnologyCNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly compl...view Excellent Corrosion Resistance of Stainless Steel-316L Stainless SteelOctober 24, 2023Dear viewers, today we are going to talk about an amazing material - 316L stainless steel. Did you know? This ordinary-looking material has amazing corrosion resistance! 316L stainless steel as a low carbon series of 316 steel, in addition to the same characteristics with 316 steel, its resistance to grain boundary corrosion is excellent, let's take a look at it!view

Excellent Corrosion Resistance of Stainless Steel-316L Stainless SteelOctober 24, 2023Dear viewers, today we are going to talk about an amazing material - 316L stainless steel. Did you know? This ordinary-looking material has amazing corrosion resistance! 316L stainless steel as a low carbon series of 316 steel, in addition to the same characteristics with 316 steel, its resistance to grain boundary corrosion is excellent, let's take a look at it!view