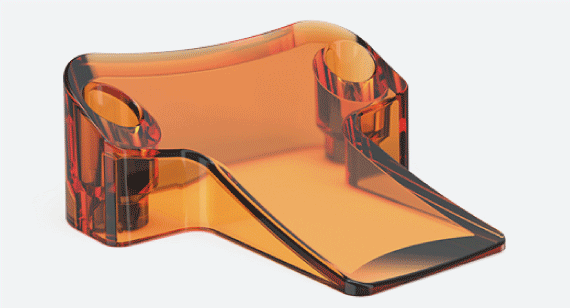

The manufacturing sector is constantly evolving as new trends and processes emerge. Among the most interesting trends is the relatively new idea of designers to replace metal parts with plastic injection molding.

If this trend is new to you, the idea may seem a bit unusual. Ever since mankind learned how to machine the material, metal parts have been the gold standard in many applications.

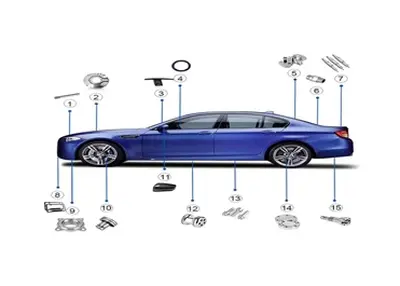

However, with advances in both technology and materials, this view is slowly beginning to be challenged. In many high-tech industries, such as automotive and aerospace, there has been a significant shift toward the use of advanced, sophisticated plastics in areas that were once the exclusive domain of metals.

The exact reasons for this can vary from part to part, but there are several factors that typically come into play:

* Weight

* Strength

* Reliability

* Sustainability

* Surface area

* Cost

One of the most important reasons for switching to plastics is weight. In the vast majority of situations, metal parts are heavier than plastic parts. And when these parts are incorporated into a high-performance car or even an airplane, every single gram that can be saved in the design can lead to improved performance.

But weight doesn't just play a role in billion-dollar high-performance projects. Even relatively mundane products can benefit from weight reduction when it comes to factors such as ease of use and transportation costs. Even a seemingly minor reduction of ten percent can have a noticeable impact on the amount you pay to get your product to customers or into stores.

While it's true that metals are generally stronger than plastics, in fact, switching to plastic components can result in increased strength and performance in certain situations. Engineering plastics can outperform metals in terms of tensile strength - the maximum load a material can take when stretched before breaking.

This advantage is particularly evident when considering strength-to-weight ratios, a factor that is of paramount importance in many applications.

In addition, plastic parts can be more reliable and stronger over time than their metal counterparts. This is due to the use of additives in the plastic that slow oxidation and degradation processes, which in turn increases the durability of the product.

Many plastics also have greater chemical resistance than metals and do not corrode as easily. This often has the advantage of reducing the need to treat products and parts before they are used, or making it possible to sell products that last longer or require less maintenance.

Despite improved reliability, every product eventually reaches the end of its useful life. Even in this case, plastics can offer an advantage because they are much easier to recycle. Melting and remelting metals takes much more time and energy than recycling thermoplastics.

Although surface finish is rarely important for internal parts, for external parts, the various finishes of plastics can offer many advantages over the uniform metallic appearance of metals. Injection molded plastic parts can be produced with virtually any color or texture imaginable.

So not only can designers show off their creativity, but they can also easily add a company logo to parts. You don't have to paint or glue a logo on, you can make it an integral part of the design.

The smooth surface of plastics can also be an advantage for finishing. Plastic parts don't need to be deburred as intensively as metal parts, and assembling the finished product is much easier because there's no welding involved.

Plastic parts are generally much less expensive to manufacture than metal parts. There are also lower shipping and assembly costs. Since the cycle time for injection molding plastic parts is much shorter than for metal parts, such plastic parts are generally easier and less expensive to produce.

Of course, plastics will never be able to replace metals in every situation, but their use is certainly worth considering. If in doubt, you can always consult the experts if you plan to replace some metal parts with plastic ones.

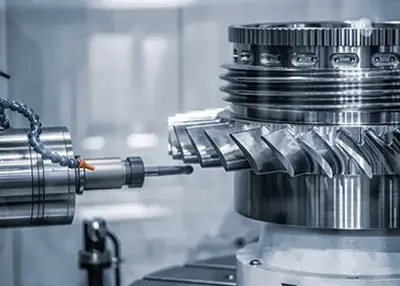

The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view

The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view What Are the Processing Principles of Precision Machining?December 30, 2022What are the processing principles of precision CNC machining? What safety precautions are there when performing precision CNC machining?1. Processing principles of precision NC machining (1) In order...view

What Are the Processing Principles of Precision Machining?December 30, 2022What are the processing principles of precision CNC machining? What safety precautions are there when performing precision CNC machining?1. Processing principles of precision NC machining (1) In order...view How to DIY CNC Machine?November 2, 2023Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.view

How to DIY CNC Machine?November 2, 2023Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.view The Importance of Material Science in Component Interaction.October 18, 2023Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.view

The Importance of Material Science in Component Interaction.October 18, 2023Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.view What Are The 3-Axis, 4-Axis, And 5-Axis In Cnc Machining, And What Is The Difference Between Them?June 21, 20223-axis CNC machining, 4-axis CNC machining, and 5-axis CNC machining are terms that are often heard in our industry work. Some users can't tell. For these types of CNC machining, there are still C...view

What Are The 3-Axis, 4-Axis, And 5-Axis In Cnc Machining, And What Is The Difference Between Them?June 21, 20223-axis CNC machining, 4-axis CNC machining, and 5-axis CNC machining are terms that are often heard in our industry work. Some users can't tell. For these types of CNC machining, there are still C...view Safety Issues in CNC Turning TechnologyApril 25, 2023Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves,...view

Safety Issues in CNC Turning TechnologyApril 25, 2023Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves,...view

EN

EN

ru

ru