Hot chamber die casting is a metal casting process used to create complex-shaped metal parts and has applications in industrial products such as heavy machinery, gears, construction materials and even vehicles. Richconn provides hot chamber die casting services for your metal parts, materials include aluminum alloy, magnesium alloy, zinc alloy, copper alloy.

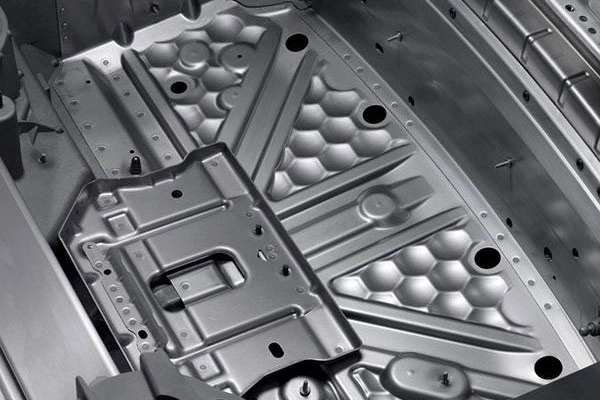

Hot chamber die casting is a metal casting process typically used to produce metal parts with complex geometries and high quality requirements. The process involves heating a metal alloy (usually an aluminum, zinc or magnesium alloy) to a liquid state and then injecting the molten metal into a metal mold to create the desired shape of the part. Hot chamber die casting is commonly used to produce high-precision parts such as automotive parts, electronic equipment housings, and industrial machinery parts. The process is very popular in many applications because it provides excellent surface quality and complex geometries.

The hot chamber die casting process offers several advantages over cold chamber die casting. It enables the production of high-precision parts with superior dimensional accuracy and surface quality, reduces porosity and impurities, is suitable for a wide range of metal alloys including aluminum, zinc, and magnesium, and creates thin-walled parts and complex geometries, often without the need for secondary operations. In addition, hot chamber die casting does not waste a lot of material and is more environmentally friendly. However, it also has some limitations, such as high equipment costs, unsuitability for high-volume production and possible challenges when working with metals with high melting points. Therefore, engineers need to weigh specific project needs and material choices when making a selection.

Due to the design characteristics of hot chamber die casting machines, this method is only suitable for those metal alloys that have relatively low melting points. Certain hot chamber die casting machine components have difficulty with high temperatures and are therefore only suitable for handling metal alloys with melting points between 600°F and 1200°F.

Hot chamber die casting allows for easy mass production because the parts are made in a die casting mold with little or no machining and thousands of identical castings can be produced.Richconn hot chamber die cast parts offer superior dimensional accuracy and stability, heat resistance and durability. They are stronger than injection-molded parts of the same size, especially thin-walled castings, because they are not made from multiple individual parts welded or fastened together, and their strength is largely dependent on the alloy itself.

Richconn has extensive experience as a die casting supplier in China. We also offer cold chamber die casting processes to meet the needs of different applications. Whichever process you require, the experts at Richconn Die Casting can provide customized advice on project requirements and provide you with a quote for your hot chamber die casting project. Since 2008, Richconn has been your trusted die casting and machining supplier, providing quality solutions for your projects.

Achieve complex part shapes and improve part performance: The process allows for the manufacture of parts with complex shapes, which can improve part performance without the need for tedious assembly work.

Produce durable and dimensionally stable die castings: Richconn hot chamber die casting allows for durable die castings with specified shapes that often require no or minimal machining.

Multiple Finishing Techniques and Surface Treatment Options: Die castings can be finished using a variety of finishing techniques to achieve smooth or textured part surfaces.

Achievement of Net Shape Part Configurations: The Richconn hot chamber die casting process helps produce net shape part configurations with fewer subsequent processing steps.

Reduce casting defects: The process helps reduce part porosity and improve part quality.

Extended Mold Life: Richconn hot chamber die casting molds last longer due to their lower melting point, increasing the efficiency of mold design and reducing waste.

Fast production cycle times: The process has fast cycle times of approximately 15 cycles per minute, resulting in increased productivity.

Convenient metal melting: In casting machinery, the Richconn hot chamber die casting process provides a convenient way to melt metal, making the production process more efficient.

We proudly sell our hot chamber die casting products all over the world, including the United States, Canada, Australia, the United Kingdom, Germany, France, South Africa, and more. Our manufacturing processes are ISO 9001-2015 certified and have been reviewed by SGS for certification.

We specialize in providing you with tailor-made hot chamber die casting services in China, aiming to provide costeffective and durable castings to meet your specific needs in a wide range of industries, including automotive, medical, aerospace, electronics, food, construction, security, marine, and more. You can quickly send your inquiry or submit relevant drawings now so that we can provide you with a free quote in the shortest possible time. Why not contact us at or send an email to sales@richconn.com.cn to learn more about how our team, equipment, and tools can provide superior quality and the most competitive pricing for your hot chamber die casting project.

When you have a complex part design, Richconn Casting Company is your trusted partner in transforming it into a tangible product. With state-of-the-art equipment, extensive technical expertise and an unwavering commitment to quality, we guide your project from the initial tool design through the finishing stages, guaranteeing each stage is executed to exacting standards and your order Consistently delivered on time.

EN

EN

ru

ru