Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an indispensable step and also affects the success or failure of subsequent surface treatment. Therefore, metal pretreatment technology plays a very important role in surface treatment technology and engineering. Today, let's take a look at the purpose and importance of metal surface pretreatment.

Preparation for metal coating technology and metal protection technology mainly includes substrate pretreatment such as degreasing, rust removal, phosphating, rust prevention, etc. The quality of substrate pretreatment has a great impact on subsequent coating preparation and the use of metals. For example, if the same coating is subjected to salt spray test after phosphatization and non-phosphatization treatment, the result is that the corrosion resistance ability differs by about twice. Therefore, degreasing, rust removal, rust prevention, phosphating, and oil stain cleaning agents play a crucial role in the rust prevention ability of coatings and the protection ability of metals.

Metal surface treatment increases the bond strength between the coating and the substrate, i.e. increases adhesion.

Metal surface finish improves the functions of the coating, such as corrosion resistance, wear resistance, and lubrication, etc.

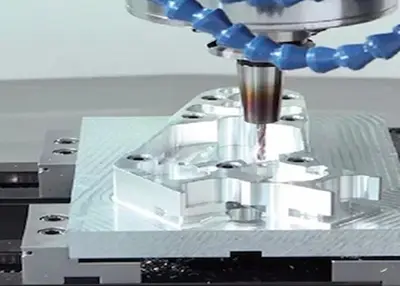

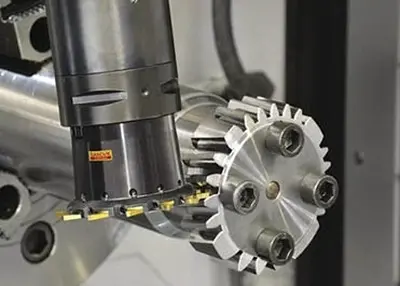

The rapid development of railway manufacturing industry, metal processing industry, and automobile industry has put higher demands on the quality of various metal products and railway and automotive parts products. Through long-term practice, some simple and easy pretreatment and cleaning methods with heavy oil stain cleaning agents cannot meet the basic requirements of metal processing and coating. Therefore, choosing low-cost, low-energy-consumption, and high-quality CNC surface finish products is an important factor for enterprises to ensure the stability of coating quality and protection quality.

Degreasing and oil stain cleaning is the first barrier of metal finishing tech. The main factor affecting the next process operation is whether degreasing is thorough, which also affects the quality and service life of the entire product. From the processing of materials to various links in the process of part machining, as well as the oil stains attached to prevent rust and corrosion during storage and transportation, these are all oil stains on the surface of metal, usually cleaned with oil stain cleaning agents.

The requirements of special industries for metal surface finish are extremely strict, such as the surface cleanliness level, primer, topcoat, and protective coating type of parts and products in extreme weather conditions. Shenzhen Richconn Technology has a complete surface finishing plant. Metals can be sprayed with tungsten carbide, zirconia, alumina, nitrided, carburized, electrophoretic, vacuum-coated (PVD), electroplated with nickel, zinc, chrome, sandblasted, anodized, fluorinated, fingerprint protection coating, etc. Welcome to consult online for different CNC machining materials!

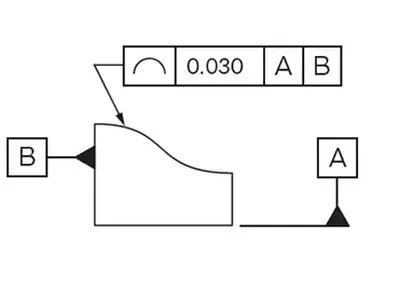

Unveiling the Precision: The Line Profile UnraveledNovember 21, 2023In the vast realm of engineering and manufacturing, the significance of line profiles cannot be overstated. These seemingly simple geometric elements play a pivotal role in ensuring precision, guiding us through the intricacies of design and production.view

Unveiling the Precision: The Line Profile UnraveledNovember 21, 2023In the vast realm of engineering and manufacturing, the significance of line profiles cannot be overstated. These seemingly simple geometric elements play a pivotal role in ensuring precision, guiding us through the intricacies of design and production.view What is CNC: Unveiling the Precision RevolutionSeptember 20, 2023CNC (Computer Numerical Control) is an automated manufacturing technology that utilizes computer control systems to precisely manipulate machine tools and equipment for machining and manufacturing purposes.view

What is CNC: Unveiling the Precision RevolutionSeptember 20, 2023CNC (Computer Numerical Control) is an automated manufacturing technology that utilizes computer control systems to precisely manipulate machine tools and equipment for machining and manufacturing purposes.view Anodized Aluminum: A Durable and Versatile MaterialJuly 27, 2023Anodized aluminum is a metal with widespread use and advantages. It is a process of treating metal with electricity to create an oxide protective layer on the surface. This layer helps to protect alum...view

Anodized Aluminum: A Durable and Versatile MaterialJuly 27, 2023Anodized aluminum is a metal with widespread use and advantages. It is a process of treating metal with electricity to create an oxide protective layer on the surface. This layer helps to protect alum...view Challenge the Production of Mirror Discharge Mold Parts with H2 Grade Machining AccuracyMarch 2, 2023Challenge time: February 2023Challenge location: Longhua, Shenzhen, ChinaCustomer information: Singaporean high-quality mold vendorsNo nonsense, first upload the customer photo:Customer physical photo...view

Challenge the Production of Mirror Discharge Mold Parts with H2 Grade Machining AccuracyMarch 2, 2023Challenge time: February 2023Challenge location: Longhua, Shenzhen, ChinaCustomer information: Singaporean high-quality mold vendorsNo nonsense, first upload the customer photo:Customer physical photo...view Define Polished: Process, Benefits & ApplicationsAugust 31, 2023Have you ever imagined transforming a raw piece of stainless steel into a shining masterpiece? When we say something is polished, we are describing a transformation from a rough and lackl...view

Define Polished: Process, Benefits & ApplicationsAugust 31, 2023Have you ever imagined transforming a raw piece of stainless steel into a shining masterpiece? When we say something is polished, we are describing a transformation from a rough and lackl...view What is the Basic Principle of Electrophoresis Coating?September 16, 2022Electrophoresis coating is a coating method that uses an external electric field to make particles such as pigments and resins suspended in an electrophoretic solution directionally migrate and deposi...view

What is the Basic Principle of Electrophoresis Coating?September 16, 2022Electrophoresis coating is a coating method that uses an external electric field to make particles such as pigments and resins suspended in an electrophoretic solution directionally migrate and deposi...view

EN

EN

ru

ru