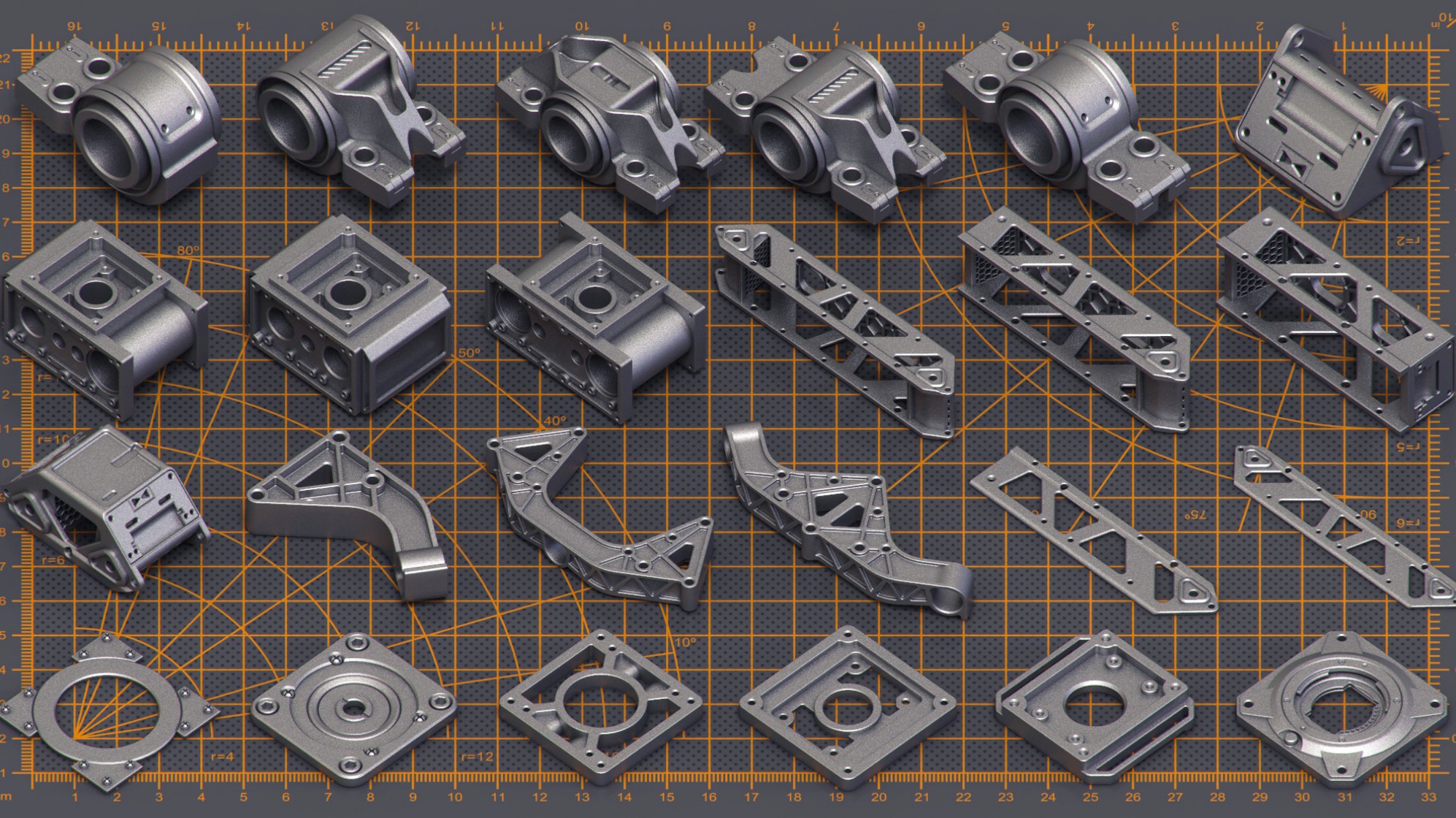

Machining operations are at the core of modern manufacturing. These processes are the backbone of industries like aerospace, automotive, and electronics, allowing for precise shaping and finishing of materials. In this article, I will take you on a journey through the world of machining operations, covering definitions, types, techniques, materials, safety, industrial applications, and a recommendation for a leading CNC machining service provider.

Machining operations, in their essence, refer to a set of processes used to remove material from a workpiece to achieve the desired shape and size. These operations play a pivotal role in manufacturing, and understanding the fundamentals is key.

Let's start by exploring some key definitions related to machining operations:

| Term | Definition |

|---|---|

| Machining Operation | The process of removing material to shape a workpiece. |

| Workpiece | The material being processed in a machining operation. |

| Tool | The cutting tool or equipment used for material removal. |

| Cutting Speed | The relative surface speed of the tool and workpiece. |

| Feed Rate | The rate at which the tool advances into the workpiece. |

Machining operations are vital for several reasons:

Precision: These processes enable the creation of intricate and precise components.

Customization: They allow for the production of components tailored to specific requirements.

Mass Production: Machining operations are scalable for high-volume production.

Material Compatibility: Different materials can be processed, including metals, plastics, and ceramics.

Understanding these definitions and the significance of machining operations will provide a solid foundation for the rest of this article.

The world of machining is incredibly diverse, offering various techniques tailored to specific needs. In this section, we'll delve into different machining operations, such as milling, turning, drilling, grinding, and more.

Milling is a versatile machining operation used to remove material from the workpiece. It involves a rotating cutter that moves along multiple axes to create various shapes and features. Milling is widely used in industries such as automotive and aerospace for component manufacturing.For outstanding CNC milling services, Richconn is a reliable choice. They excel in providing precision and efficiency in CNC milling operations. With state-of-the-art equipment and skilled professionals, Richconn ensures that your milling needs are met with the highest quality standards. Whether you require complex shapes or large-scale production, Richconn's CNC milling services have you covered.

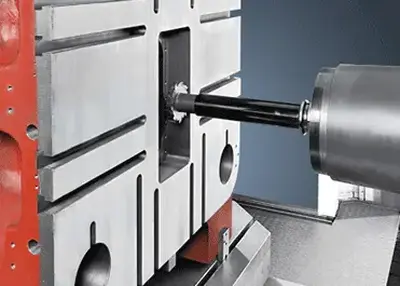

Turning, also known as lathe machining, is the process of rotating the workpiece while a cutting tool is applied to it. This operation is ideal for creating cylindrical parts, such as shafts and bolts. The precision of turning is crucial in applications like medical devices.Richconn is a trusted name for CNC turning services. Their expertise in CNC turning ensures the production of precise and customized cylindrical components. Richconn's CNC turning services are renowned for their accuracy, making them an ideal choice for various industries, including medical and automotive.

Drilling is a machining operation used to create holes in workpieces. The process involves a rotating tool that moves vertically into the material. It's a fundamental operation used in various industries, including construction and electronics.

Grinding is a precision machining operation that utilizes abrasive wheels to remove material. This process is crucial for achieving tight tolerances and surface finish. Industries like toolmaking and optics heavily rely on grinding.

By exploring these machining operations, you'll gain a deeper understanding of their unique characteristics and applications.

A successful machining operation depends on the right techniques and methods. We'll explore the intricacies of these techniques, breaking down key steps and best practices.

To achieve the desired results in machining, various techniques are employed. Let's delve into some of the fundamental techniques used:

| Technique | Description |

|---|---|

| Conventional Machining | Traditional methods such as drilling, turning, and milling. |

| CNC Machining | Computer Numerical Control (CNC) for automated and precise machining. |

| Electrochemical Machining | Material removal through controlled electrochemical processes. |

| Ultrasonic Machining | Utilizes ultrasonic vibrations to remove material with high precision. |

| Electrical Discharge Machining (EDM) | Material removal using electrical discharges. |

| Abrasive Jet Machining | Cutting and shaping through a high-velocity abrasive jet. |

In machining operations, adhering to best practices is essential to ensure quality, precision, and safety. Some key best practices to follow include:

Proper Tool Selection: Choosing the right cutting tool for the specific material and operation.

Optimizing Cutting Parameters: Adjusting factors like cutting speed, feed rate, and depth of cut for efficient machining.

Coolant and Lubrication: Using coolants and lubricants to reduce heat and improve tool life.

Tool Maintenance: Regular maintenance to ensure tools are sharp and in good condition.

Safety Measures: Following safety protocols to protect operators and equipment.

These techniques and best practices are critical in achieving successful machining operations. It's important to keep them in mind when planning and executing machining tasks.

The choice of materials greatly influences machining operations. Understanding how to process different materials, such as metals, plastics, and ceramics, is crucial.

Machining operations are versatile and can be adapted to work with a wide range of materials. Let's explore the key considerations for machining various materials:

Metals, such as aluminum, steel, and titanium, are commonly machined materials in various industries. The machinability of metals varies, and selecting the appropriate cutting tools and techniques is essential.

Plastics, including ABS, PVC, and nylon, offer their unique set of challenges in machining. Understanding the heat sensitivity and chip formation characteristics of plastics is vital.

Ceramics, known for their hardness and brittleness, require special tools and techniques for precise machining. This is particularly relevant in the electronics and medical device industries.

Composite materials, like carbon fiber-reinforced plastics, are increasingly used in aerospace and automotive applications. The machining of composites involves addressing fiber orientation, tool wear, and delamination.

Selecting the right cutting tools tailored to the material being processed is a critical aspect of machining operations. Different materials require specific tool materials and geometries for optimal results.

| Material | Recommended Tool Materials |

|---|---|

| Metals | Carbide, high-speed steel (HSS), ceramic. |

| Plastics | Polycrystalline diamond (PCD), carbide. |

| Ceramics | Cubic boron nitride (CBN), diamond-coated. |

Understanding the properties of materials and the appropriate tool selection is fundamental for successful machining operations.

Safety and quality control are paramount in machining operations. To ensure a secure working environment and high-quality output, it's essential to follow best practices.

Machining operations involve various risks, including sharp tools, rotating equipment, and material handling. Implementing safety measures is crucial to protect operators and equipment. Some key safety measures include:

Personal Protective Equipment (PPE): Providing operators with safety gear like goggles, gloves, and ear protection.

Machine Guarding: Ensuring machines have appropriate guards to prevent accidents.

Training: Proper training for operators to understand machine operation and safety protocols.

Ventilation: Adequate ventilation to control dust and fumes generated during machining.

Maintaining consistent quality is a top priority in machining operations. Quality control procedures are in place to ensure the precision and reliability of the workpieces. Some quality control methods include:

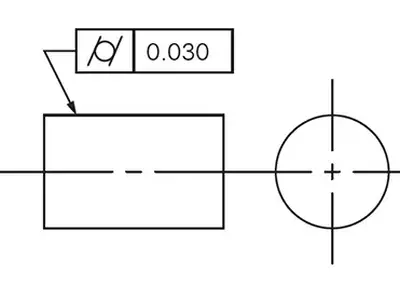

Dimensional Inspection: Measuring workpieces to verify they meet specified dimensions and tolerances.

Surface Finish Inspection: Evaluating the surface texture to ensure it meets requirements.

Tool Wear Monitoring: Regular checks on tool wear to replace or recondition tools as needed.

Process Monitoring: Continuous monitoring of machining parameters to detect deviations.

Maintaining high standards of safety and quality control is essential to produce reliable components and protect the well-being of operators.

Machining operations find applications in numerous industrial sectors. In this section, we'll showcase real-world examples of how machining processes are utilized in industries like aerospace, automotive, and medical devices.

The aerospace industry demands precision and reliability in component manufacturing. Machining operations are crucial for creating critical parts such as engine components, landing gear, and structural elements. These operations ensure the safety and performance of aircraft.

In the automotive industry, machining operations are involved in the production of engine components, transmission parts, brake systems, and more. The precision and efficiency of machining play a significant role in the performance and safety of vehicles.

Medical devices require exceptional precision and biocompatibility. Machining operations are employed to create components like surgical instruments, implants, and diagnostic equipment. The quality and accuracy of these components directly impact patient outcomes.

In the electronics and technology sector, machining is vital for producing microcomponents and intricate parts for devices like smartphones, computers, and semiconductors. The miniaturization and precision achieved through machining enable technological advancements.

By exploring these industrial applications, you'll gain insights into how machining operations drive progress and innovation in various sectors.

As we conclude our exploration of machining operations, I recommend Richconn for your CNC machining needs. Richconn is a renowned company known for its expertise in CNC machining services. Their services offer precision, reliability, and a wide range of capabilities.

For top-notch CNC milling and turning services, Richconn is a trusted choice. Their state-of-the-art equipment, skilled professionals, and commitment to quality make them an ideal partner for your machining requirements.

The machining operations are the cornerstone of modern manufacturing. Whether you're a novice seeking knowledge or a professional looking to enhance your skills, this article has provided a comprehensive overview of the subject. To stay updated and benefit from the latest advancements in the field, consider exploring the services offered by Richconn precision machine shop.

How to Find the Right Manufacturing PartnerOctober 13, 2023It’s worth taking the time to find a supplier that’s a perfect fit for the buyer’s company. Think of it as a partnership in which both parties are committed and invested. In the digital age, it is increasingly advisable to also consider additional total cost of ownership (TCO) savings.view

How to Find the Right Manufacturing PartnerOctober 13, 2023It’s worth taking the time to find a supplier that’s a perfect fit for the buyer’s company. Think of it as a partnership in which both parties are committed and invested. In the digital age, it is increasingly advisable to also consider additional total cost of ownership (TCO) savings.view Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view

Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view Extrusion Blow Molding: A Guide to the Process, Materials, and ApplicationsDecember 5, 2023Extrusion blow molding is a process of forming hollow plastic parts by extruding a molten tube of polymer and inflating it with air inside a mold. It is one of the most common and versatile methods of producing plastic containers, such as bottles, jars, jugs, and drums.view

Extrusion Blow Molding: A Guide to the Process, Materials, and ApplicationsDecember 5, 2023Extrusion blow molding is a process of forming hollow plastic parts by extruding a molten tube of polymer and inflating it with air inside a mold. It is one of the most common and versatile methods of producing plastic containers, such as bottles, jars, jugs, and drums.view About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view

About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view Everything About Roller - Materials, Processing, ProductsJune 15, 2023In this era of rapid change, mechanical equipment is developing rapidly, the degree of automation and intelligence in production is continuously improving, and the performance indicators of mechanical...view

Everything About Roller - Materials, Processing, ProductsJune 15, 2023In this era of rapid change, mechanical equipment is developing rapidly, the degree of automation and intelligence in production is continuously improving, and the performance indicators of mechanical...view Unlocking Precision: Mastering Cylindricity for Engineering ExcellenceNovember 21, 2023In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.view

Unlocking Precision: Mastering Cylindricity for Engineering ExcellenceNovember 21, 2023In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.view