In the field of precision medical device manufacturing, the choice of materials plays a crucial role in the success of the final product. CNC milling is a widely used process in this industry for its ability to produce complex and precise components with high accuracy. The selection of the right materials for CNC milling is essential to ensure the quality, performance, and durability of medical devices. In this blog, we will discuss the importance of CNC milling materials in precision medical device manufacturing.

CNC milling materials refer to the types of materials that can be used in the CNC machining process to create medical device components. These materials are selected based on various factors such as the desired properties of the final product, the complexity of the design, and the cost-effectiveness of the material. Some common CNC milling materials used in precision medical device manufacturing include metals like stainless steel, titanium, and aluminum, as well as engineering plastics like PEEK and ABS.

The selection of CNC milling materials is crucial in the manufacturing of precision medical devices for several reasons. First and foremost, the chosen material should possess the required mechanical properties, such as strength, hardness, and biocompatibility, to meet the specific functional requirements of the medical device. For instance, materials like titanium are often preferred for their high strength-to-weight ratio and corrosion resistance, making them ideal for the production of surgical instruments and implants.

Furthermore, the choice of materials can also impact the manufacturability and cost-effectiveness of the CNC machining process. Some materials may be more challenging to machine than others, leading to longer machining times, increased tool wear, and higher production costs. By carefully selecting the right CNC milling materials, manufacturers can optimize the machining process and ensure the efficient production of high-quality medical devices.

Using the right CNC milling materials in precision medical device manufacturing can offer several benefits, including:

Enhanced precision and accuracy: CNC milling allows for the production of complex and intricate components with tight tolerances, thanks to the high precision and repeatability of the machining process.

Improved quality and performance: The use of high-quality materials ensures that medical devices meet the necessary performance standards and are safe and reliable for use in medical applications.

Cost-effectiveness: By selecting materials that are suitable for CNC milling and optimizing the machining process, manufacturers can reduce production costs and improve overall profitability.

Flexibility and versatility: CNC milling materials come in a wide range of options, allowing manufacturers to choose the best material for each specific application and design requirements.

In conclusion, CNC milling materials play a crucial role in precision medical device manufacturing, as they directly impact the quality, performance, and cost-effectiveness of the final product. By choosing the right materials for CNC machining and considering factors like mechanical properties, manufacturability, and cost, manufacturers can ensure the successful production of high-quality medical devices. With advancements in CNC machining technologies and materials, the future of precision medical device manufacturing looks promising, with even more innovative and efficient solutions on the horizon.

What Are the Advantages of Cast Aluminum PartsOctober 19, 2023The continuous development of society, people's lives are increasingly high demand for aluminum casting process is also increasing in demand. In our use and use of aluminum casting process, do we understand the aluminum casting production out of aluminum die casting parts have what advantages?view

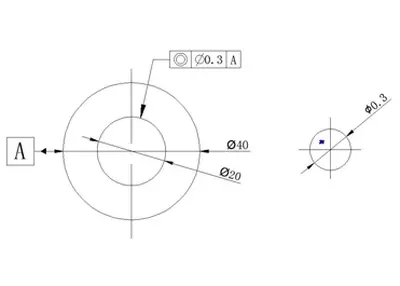

What Are the Advantages of Cast Aluminum PartsOctober 19, 2023The continuous development of society, people's lives are increasingly high demand for aluminum casting process is also increasing in demand. In our use and use of aluminum casting process, do we understand the aluminum casting production out of aluminum die casting parts have what advantages?view Positioning control - concentricity/coaxialityNovember 17, 2023When manufacturing cylindrical CNC milled parts, concentricity is the unit of measure of part accuracy. Concentricity, is the degree to which the inner diameter of the insert is offset from the center of the entire circle.view

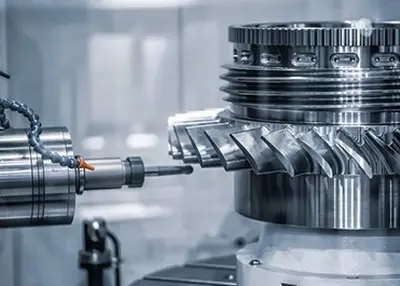

Positioning control - concentricity/coaxialityNovember 17, 2023When manufacturing cylindrical CNC milled parts, concentricity is the unit of measure of part accuracy. Concentricity, is the degree to which the inner diameter of the insert is offset from the center of the entire circle.view Machining Commonly Used 24 Kinds of MaterialsOctober 23, 2023Can be used for CNC machining, mold processing of more than a hundred kinds of materials, metal, plastic, but according to the actual needs of different, each material use as well as the demand varies, the most commonly used 24 kinds of materials.view

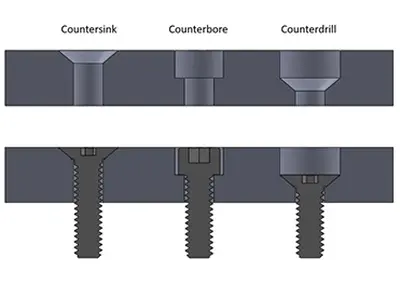

Machining Commonly Used 24 Kinds of MaterialsOctober 23, 2023Can be used for CNC machining, mold processing of more than a hundred kinds of materials, metal, plastic, but according to the actual needs of different, each material use as well as the demand varies, the most commonly used 24 kinds of materials.view What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view

What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view Protect, Enhance, Beautify: The Versatility of Blackening Surface TreatmentsDecember 4, 2023Surface treatments play a vital role in maintaining and enhancing the durability and appearance of various materials. Whether it is for aesthetic purposes, rust prevention, or to improve wear resistan...view

Protect, Enhance, Beautify: The Versatility of Blackening Surface TreatmentsDecember 4, 2023Surface treatments play a vital role in maintaining and enhancing the durability and appearance of various materials. Whether it is for aesthetic purposes, rust prevention, or to improve wear resistan...view What Is the Difference Between 304 Stainless Steel and 316 Stainless Steel?October 27, 2023It is alloyed from steel, chromium, nickel and other elements, where steel is the main component of stainless steel, while chromium is the main corrosion prevention element of stainless steel, and nickel helps to improve the corrosion resistance and strength of stainless steel.view

What Is the Difference Between 304 Stainless Steel and 316 Stainless Steel?October 27, 2023It is alloyed from steel, chromium, nickel and other elements, where steel is the main component of stainless steel, while chromium is the main corrosion prevention element of stainless steel, and nickel helps to improve the corrosion resistance and strength of stainless steel.view

EN

EN

ru

ru